-

长波红外8~14 μm光谱区域既是大气窗口,也是常温物体热辐射能量的集中波段。在此区域工作的被动式光电系统主要探测目标源自身的热辐射,可全天时工作、无源、隐蔽性好,军事上可用于目标侦察、捕获及跟踪等,也可用于森林火灾预警、夜间安全监视及搜索救援等应用领域。遥感应用的长波红外探测仪器,通常搭载在卫星、飞机及无人机等平台[1- 2]上,近年来,无人机应用研究热潮涌起,美国不断推进无人机载多光谱成像传感器的使用,2018年3月,美国海军陆战队首次部署小型四旋翼即时眼无人机,飞行高度可达3 657.6 m,搭载了3个红外光电传感器和1个前视热红外传感器。2018年7月,俄罗斯Zala公司借助激光雷达更好的态势感知和更快的数据收集能力,首次在无人机上部署了激光雷达。目前,以色列拉法尔公司的“无人机穹”搭载的MEOS光电传感器,可以实现3.2 km外最小尺寸为20 cm2的目标探测,瞬时视场为0.14 mrad[3]。适用于无人机的光电载荷在功能和性能上发展迅速,能昼夜实时获取高质量的图像和数据,很大程度上提升了侦察监视和目标捕获的能力。然而,由于无人机的携带能力有限,要求载荷性能高、质量轻、体积小,同时面向商业和大规模批量化应用时,亦具备成本低的特点。光电吊舱由于具备姿态大范围高精度可控的优势,在无人机平台上应用较多,而安装在光电吊舱中的光电仪器,其体积和重量约束更为苛刻,其光学系统需要考虑轻小紧凑型的设计。

随着红外光学系统小型化、轻量化的发展趋势,往往使光学镜片的面型更复杂,同时对锗和硒化锌等红外硬脆性材料的光学表面的微观质量也提出了更高的要求。目前,单点金刚石车削技术已经广泛用于红外光学零件的冷加工,在材料和其他参数一定前提下,单点金刚石车削精度、车削参数和机床震动可以达到最优,是目前获得优质均匀红外车削非球面表面的加工方法。

笔者根据仪器的指标要求和平台约束,面向制冷探测器的应用,提出一种简化主光学形式的轻小紧凑折反光学结构,适用于批量化生产的无人机光电吊舱长波红外相机。下文将对此相机的光学设计、加工检测装调及成像实验详细阐述。

-

光学系统安装在光电吊舱内搭载在无人机上,仪器视场中等,通过光电吊舱的二维旋转实现广域目标搜索,发现目标并锁定进行跟踪。

如图1所示,光电吊舱采用球型结构,吊舱半径小于200 mm,窗口口径为165 mm,光学空间为320 mm×310 mm×302 mm(含探测器),要求相机光机质量小于2.0 kg (不含转台及电子设备)。

-

为提高仪器探测器灵敏度,整机选用制冷面阵探测器,像元规模nx×ny为320×256,像元尺寸p为30 μm×30 μm,光学系统设计参数如表1所示。

Parameter Value Wavelength /μm 8-12.5 Focal length /mm 300 F number 2 IFOV/mrad 0.1 Observation range/(°) Azimuth:0-360, Pitch: 0-90 Detection distance/km 100 Field of view/(°) 2.34(1.83×1.47) Distortion Less than 3% Table 1. Parameters of optical system

根据仪器最远探测距离[4]要求,解得系统口径D为150 mm。探测器F数为2,则系统焦距f为300 mm,瞬时视场IFOV=p/f=0.1 mrad,即百公里处的目标分辨率为10 m,视场FOV为:

即对角线圆视场为2.34°。

-

红外光学系统结构包括透射式、反射式和折反式结构。透射镜组由于可选材料少、100%冷屏匹配则前方透镜口径较大、体积重量较大,但加工装调相对容易,适用于中小口径、中低分辨率、大视场场合;反射式系统无色差,但视场相对较小,装调相对较难,适用于中大口径、中高分辨率、小视场场合;折反式系统兼具前两者优点,像差校正能力较强,体积较紧凑,可通过二次成像,实现100%冷屏匹配,适用于中大口径、中高分辨率、中等视场场合。

鉴于以上比较分析,结合无人机装载平台对仪器体积重量资源和探测距离等需求,该系统选择折反光学结构,同时考虑到加工检测及装调的成本和周期,面向制冷探测器的应用,光学设计中提出了一种简化主光学形式的折反光学结构。

-

较多参考文献中的折反式红外相机光学系统采用的两反主系统加校正镜组形式的结构,其光学设计通常先求解两镜式结构的初始解,再加入透镜组进行优化,根据设定的遮拦比和要校正的像差[5]种类,设定对应的像差系数为零,求解出主次镜的曲率半径、圆锥系数和中心间隔,再进行放大,即可进行两镜系统的初始建模。常用的折反式系统中,其主光学为校正球差和彗差的卡式结构,主镜和次镜均为双曲面,其后方加校正镜组,校正镜组一般采用球面面型。

该系统从体积重量、装调难度、研制成本和使用环境考虑,对常用的折反系统进行简化。简化的折反式系统由牛顿折叠主系统加校正镜组组成,主系统的主镜简化为抛物面,次镜简化为平面镜,次镜无光焦度仅用于折叠光路,在校正镜组中加入非球面以校正轴外像差。

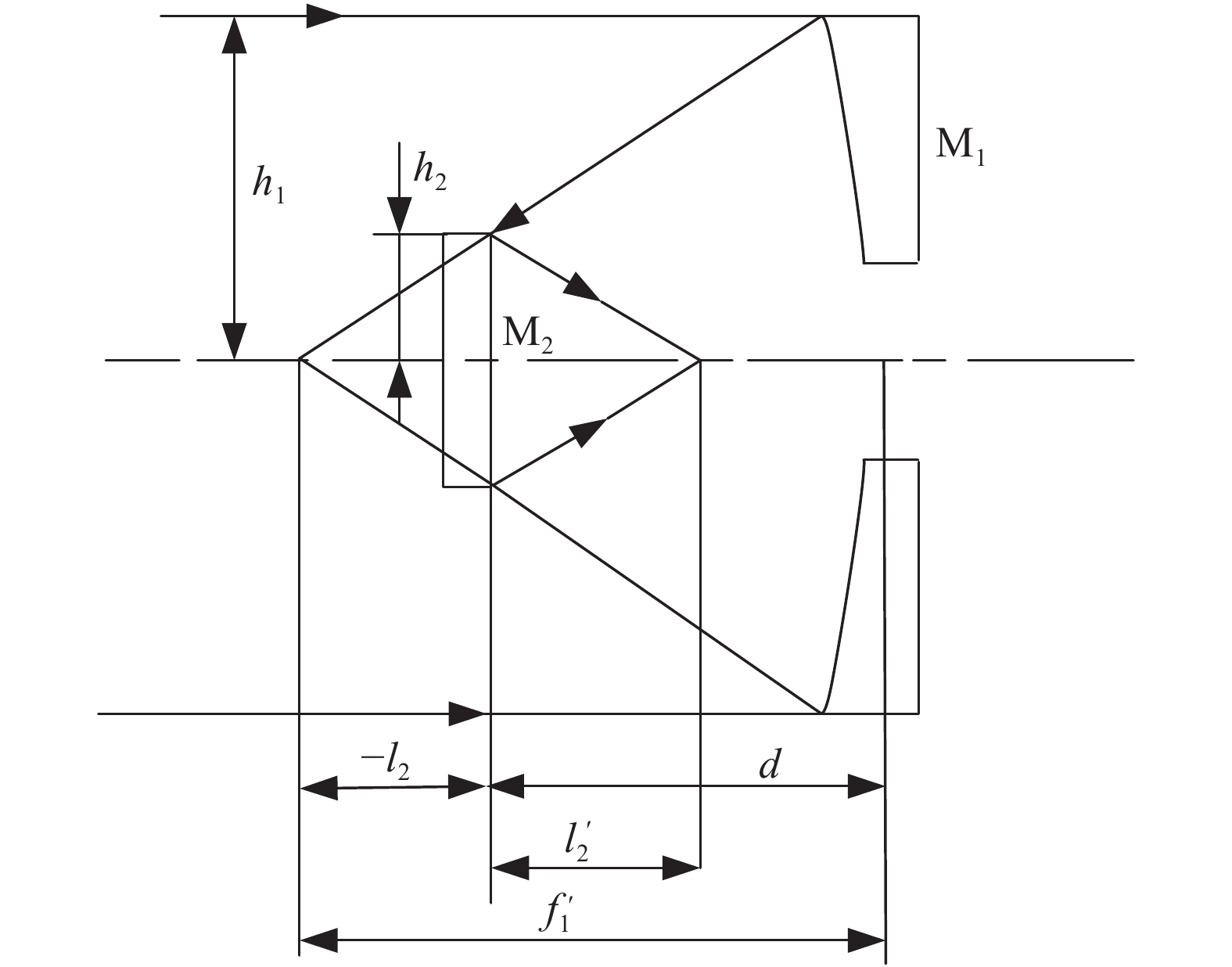

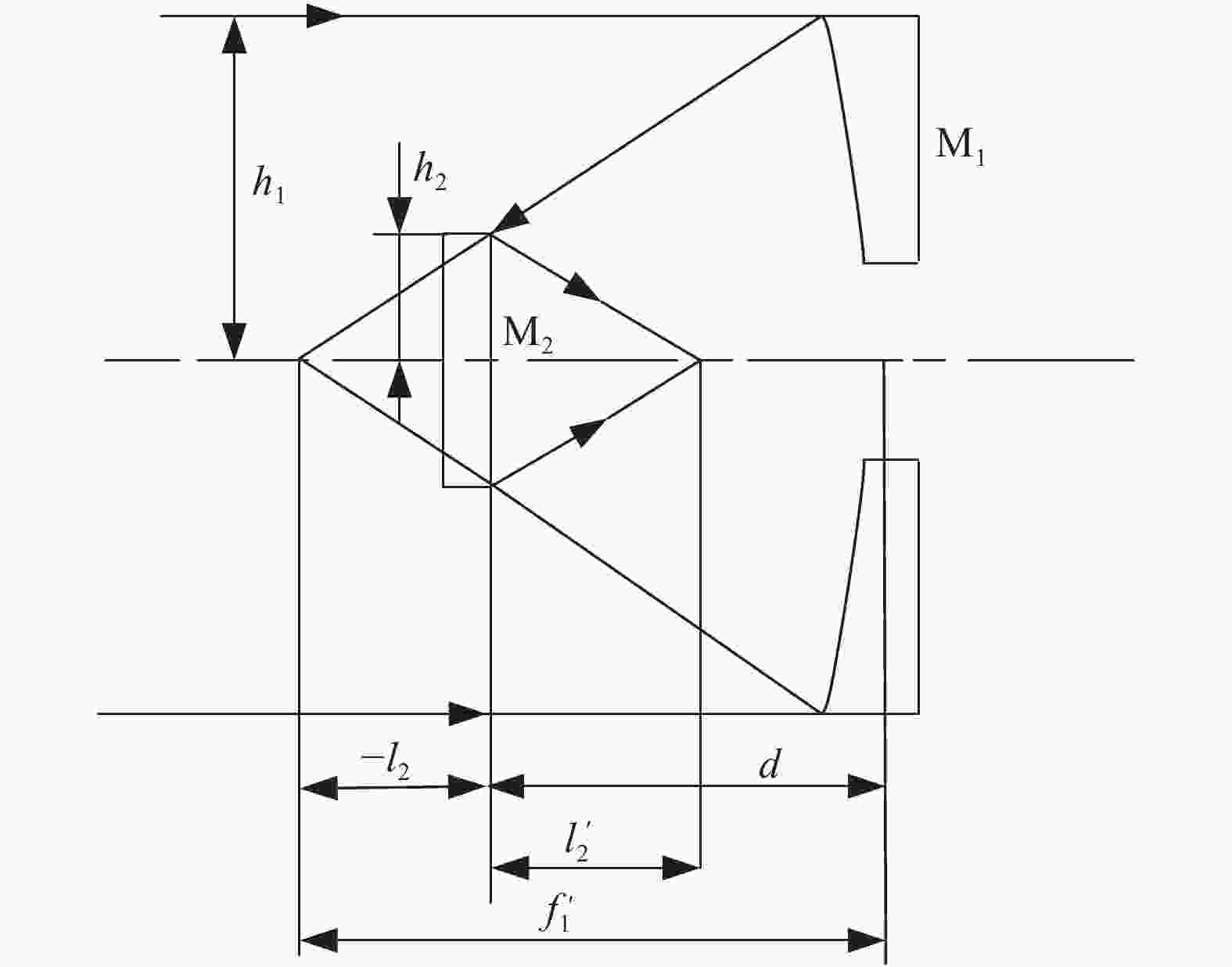

简化的牛顿折叠主系统光路示意图如图2所示,其中

$ {h}_{1} $ 、$ {h}_{2} $ 分别为中心视场边缘光线主次镜上的高度,$ {l}_{2} $ 、$ {{l}_{2}}^{'} $ 分别为次镜的物距和像距,$ {{f}_{1}}^{'} $ 为主镜焦距,$ {R}_{01} $ 为主镜中心曲率半径,$ {R}_{2} $ 为次镜曲率半径,d为主次镜间隔,α为次镜遮拦比,β为次镜放大倍率。对于简化的系统有下列表达式成立:系统的初始结构求解步骤为:(1)分配主光学和校正透镜的光焦度,确定f1′,根据公式(4)确定主镜中心曲率半径

$ {R}_{01} $ ;(2)设定遮拦比α,根据公式(5)求解主次镜间隔d;(3)初步分配校正镜组的光焦度,设定校正镜组的物距。这种设计[6-11]的优点是:抛物面主镜的加工和装调的检测,无需设计补偿镜或全息片,主光学系统的装调主要是主抛物面镜的无应力安装,检测调整比较简单,研制成本低,研制周期短;把非球面移到校正镜组的透镜上,采用单点金刚石车削技术加工,旋转对称非球面和球面的加工工序和成本基本相同,而且小口径透镜面形精度高;光学系统出瞳在校正镜组后方,与探测器冷屏对接,实现100%冷屏匹配,减少热背景影响,提高灵敏度;校正镜组在主次镜之间,系统焦面在主镜附近,探测器的制冷组件和安装部位在主镜背面,有利于缩短相机体积和探测器安装。以上优点适合于轻小紧凑系统的快速批量化研制。

-

将初始结构输入至软件中,简便起见,校正镜组以光焦度按正、负、负、正分配,设定探测器芯面前19.8 mm(冷屏所在处)为系统出瞳(或STOP),编辑绩优函数控制镜片厚度、间隔、焦距、畸变和像质等,尽量控制入瞳在主镜附近进行光线追迹。设计结果如表2所示。

Radius /mm Thickness/mm Glass M1 –309.2 –111.2 Mirror M2 Infinity 46.1 Mirror L1 –14.7 6.0 Germanium –17.1 9.7 L2 –99.6 6.0 ZnSe –250.9 2.92 L3 27.7 5.9 Germanium 23.5 2.1 L4 37.9 7.0 Germanium –368.1 6.6 Window Infinity 1.0 Germanium Infinity 2.7 Filter Infinity 0.3 Germanium Infinity 19.8 Table 2. Lens data of system design

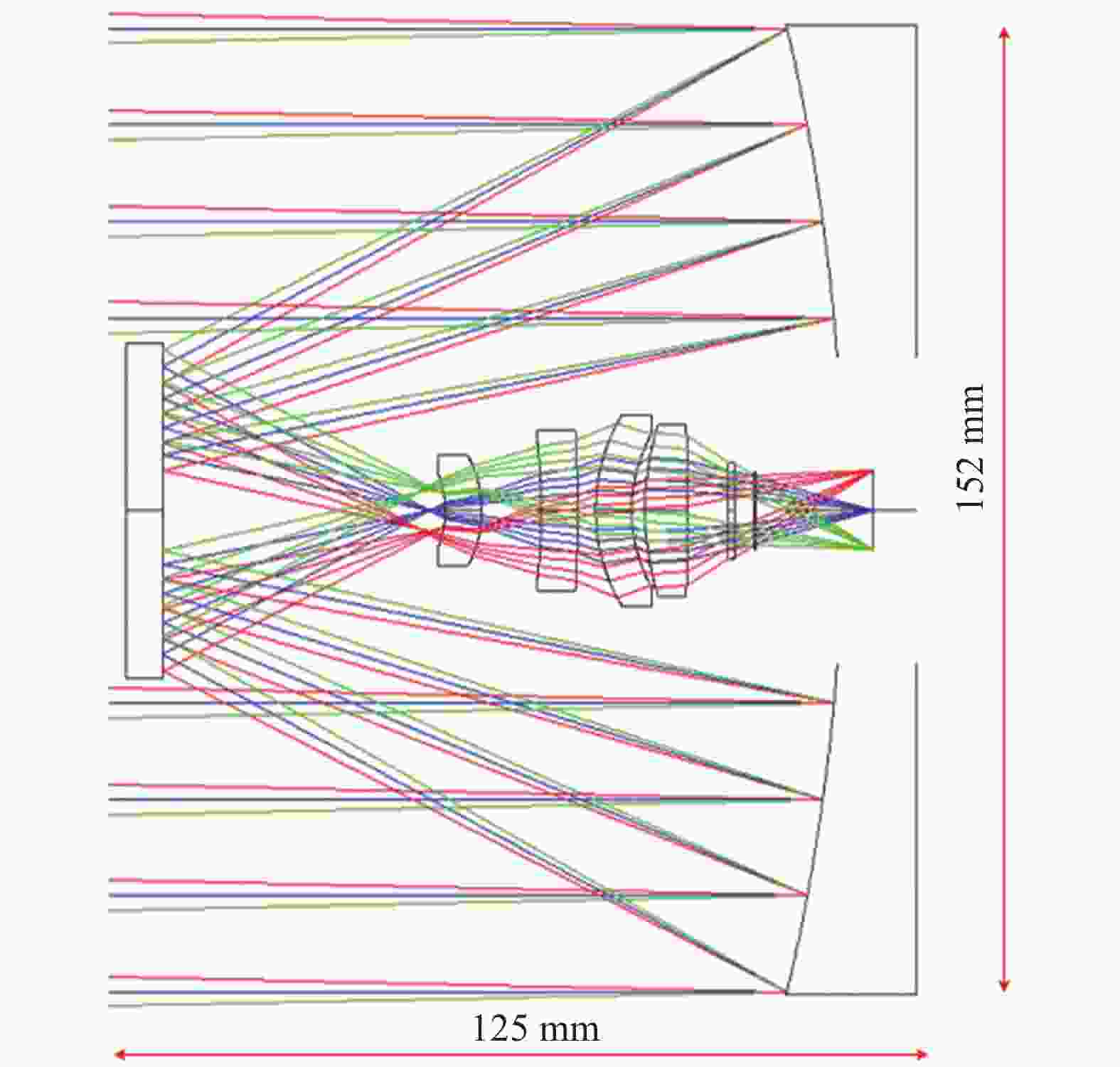

图3是红外相机光路图,主镜为抛物面,次镜为平面,校正镜组中镜1的前表面和镜3的后表面为二次曲面,系统轴向总长为125 mm。

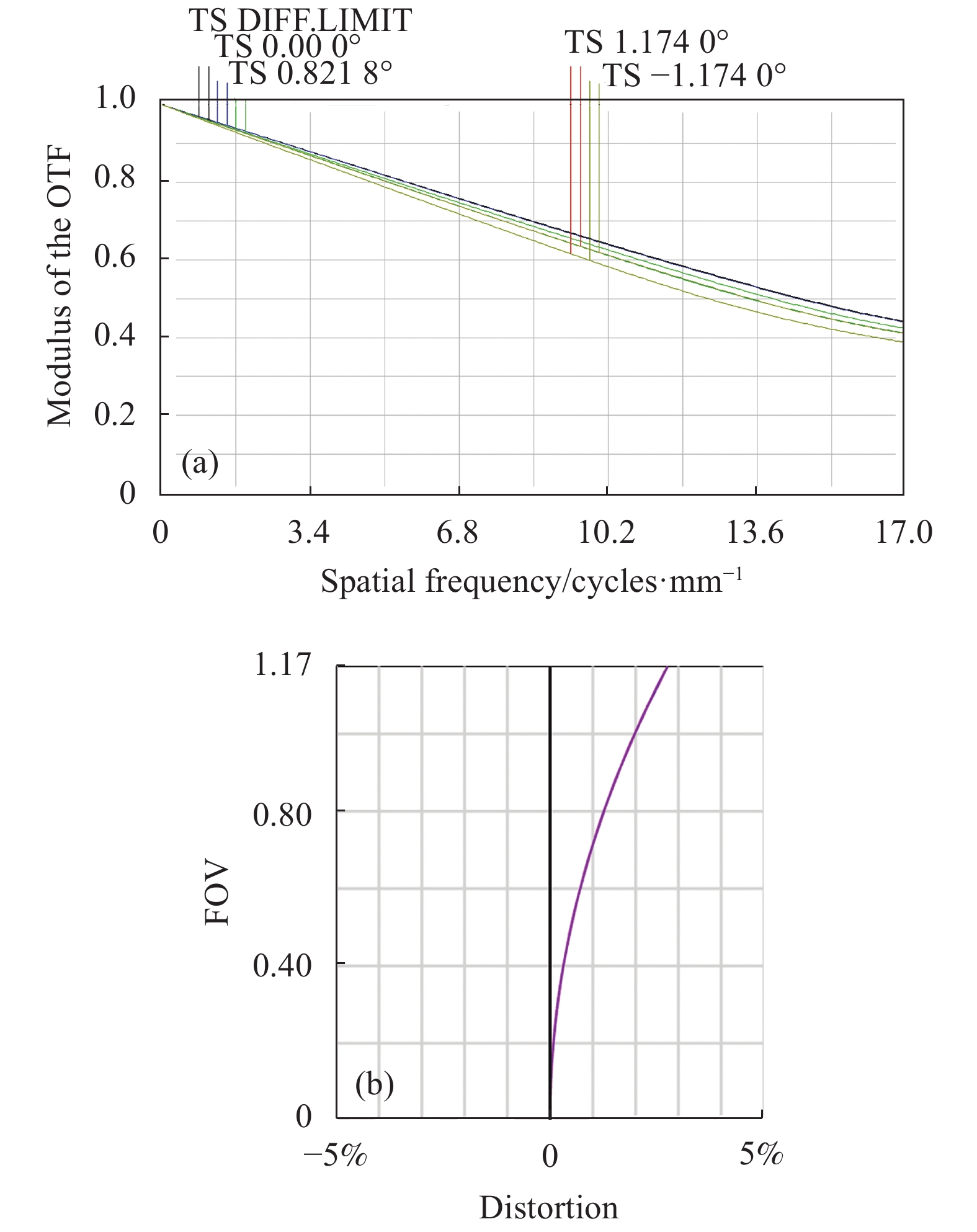

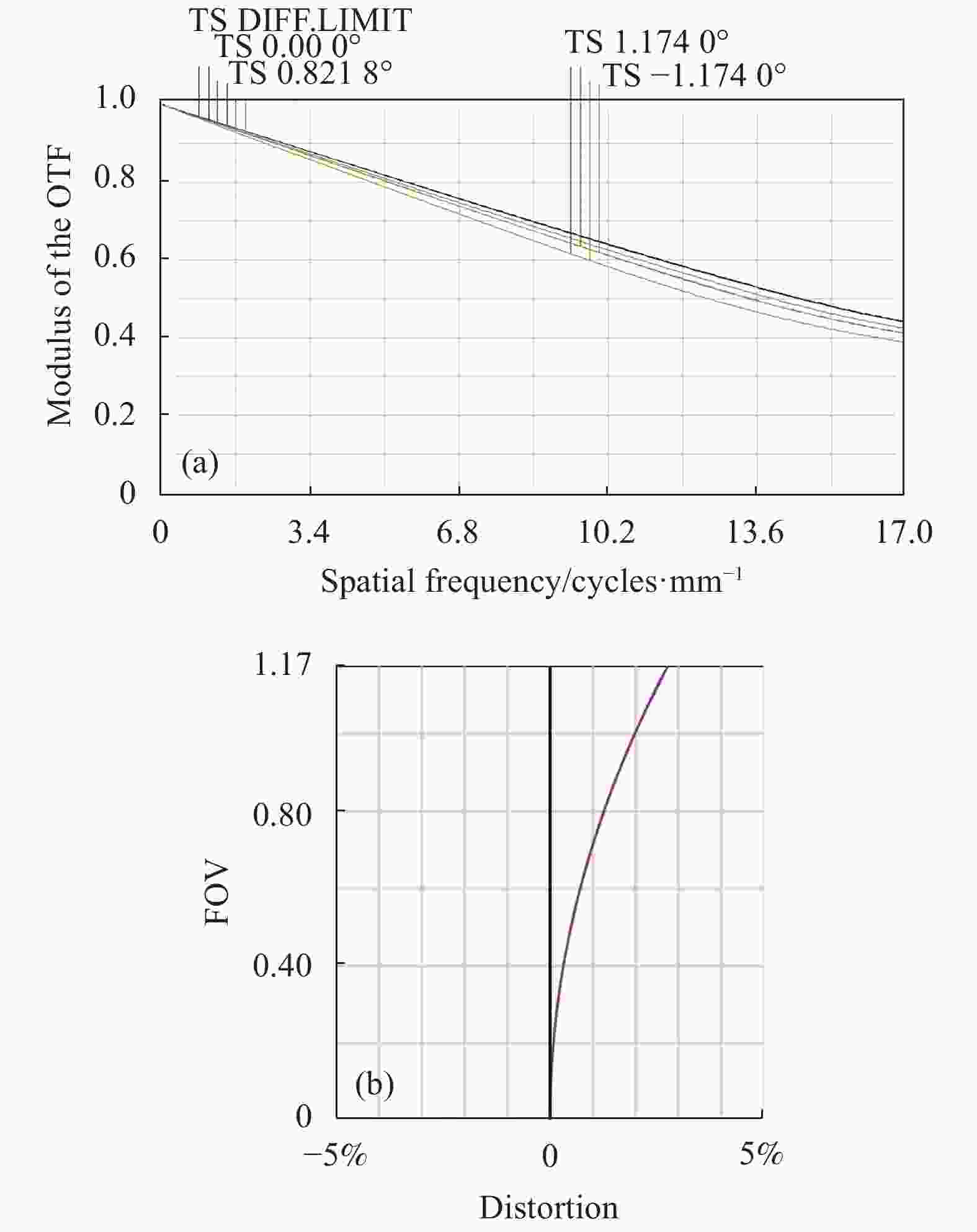

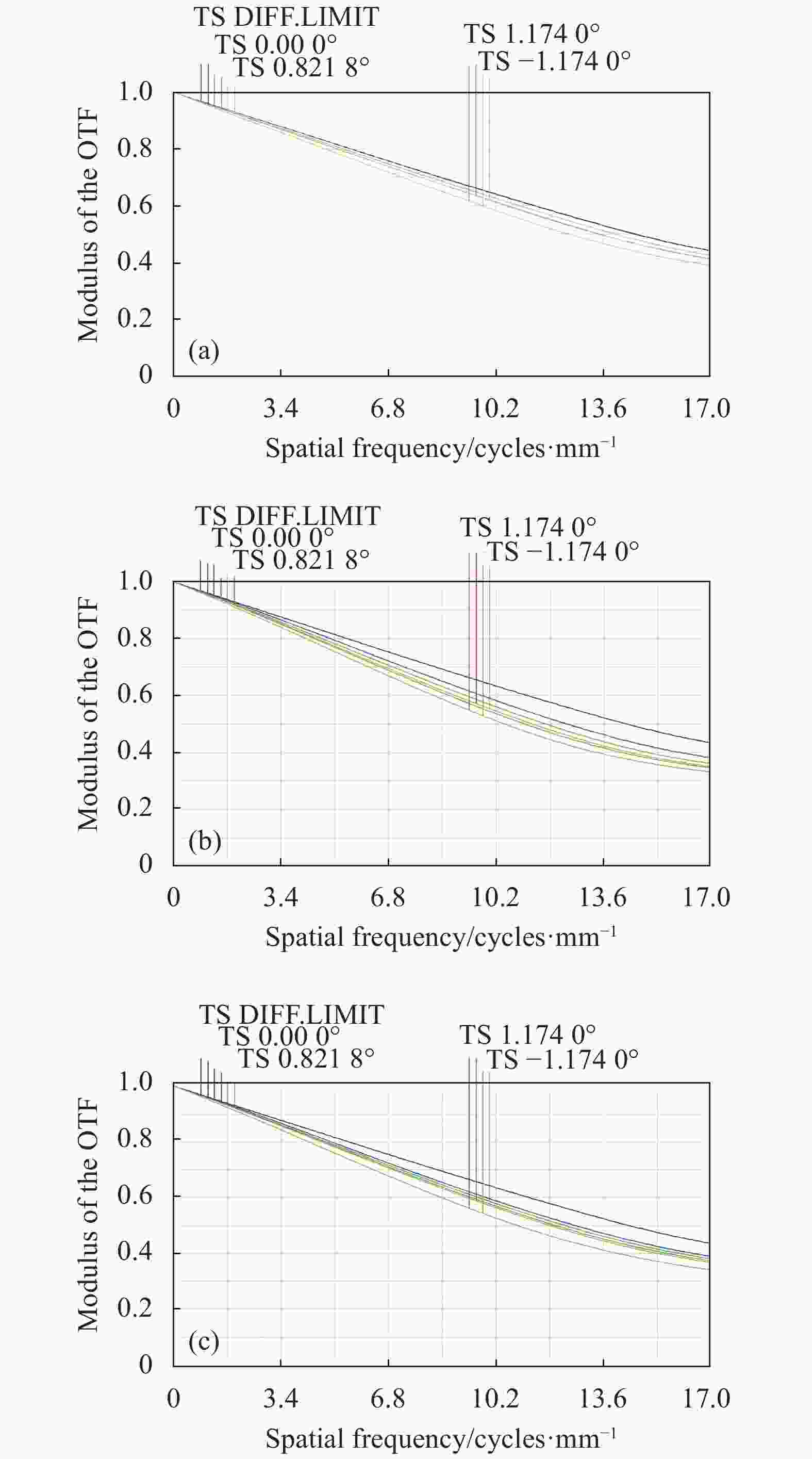

如图4所示,8~12.5 μm光谱范围内的各视场MTF值在奈奎斯特频率处接近衍射受限值,均大于0.4;系统畸变全视场内小于2.8%。

-

公差分析是为光机零件加工和组部件装调提供精度控制参考值。该系统设定光学镜片的面型、面偏心和倾斜、元件偏心和倾斜、中心厚度和间隔,设定焦面补偿变量,通过蒙特卡洛随机分析得出最敏感参数,调整敏感参数使得蒙特卡洛法分析使传函的下降量在15%以内。

对全系统进行了公差分析,敏感公差项列于表3,较弯曲的第3片透镜的表面偏心(TSD)和倾斜(TST)比较敏感,在光机系统研制过程中需予以重视。其余未列出公差比较常规。

Parameter Value Decrease of MTF TSDX3_rear 0.015 mm 0.065 TSDX3_front 0.015 mm 0.065 TSDY3_rear 0.015 mm 0.064 TSDY3_front 0.015 mm 0.063 Table 3. The most sensitive tolerance

-

无热控情况下,无人机载光电吊舱的工作环境温度约为–40~60 ℃。但考虑成本和光电吊舱给予光学系统的体积资源,其热设计方案为:初级热控结合有限温度范围内光学适应性设计。即通过初级热控控制光电吊舱内温度在15~25 ℃,(径向温差小于2 ℃,轴向温差小于5 ℃),在此温度范围内,在不调焦的情况下,需要仪器像面温漂能满足空间分辨率要求。这样,初步热控较易实现,既减轻了光学系统的压力,代价较小,但系统性能能满足载荷应用需求。

校正镜组通过材料匹配和光焦度分配,在以上工作温度范围内有效的消热差,具有结构简单,重量体积较小的特点。主系统的光机材料均采用铝金属,校正镜组采用锗、硒化锌、锗、锗4片透镜,镜筒结构采用铝材。

相机的环境适应性方案是采取初级热控和有限温度范围内的光学适应性设计。权衡光电吊舱给予光学系统的体积资源,通过初级热控控制光电吊舱内温度在15 ~25 ℃。

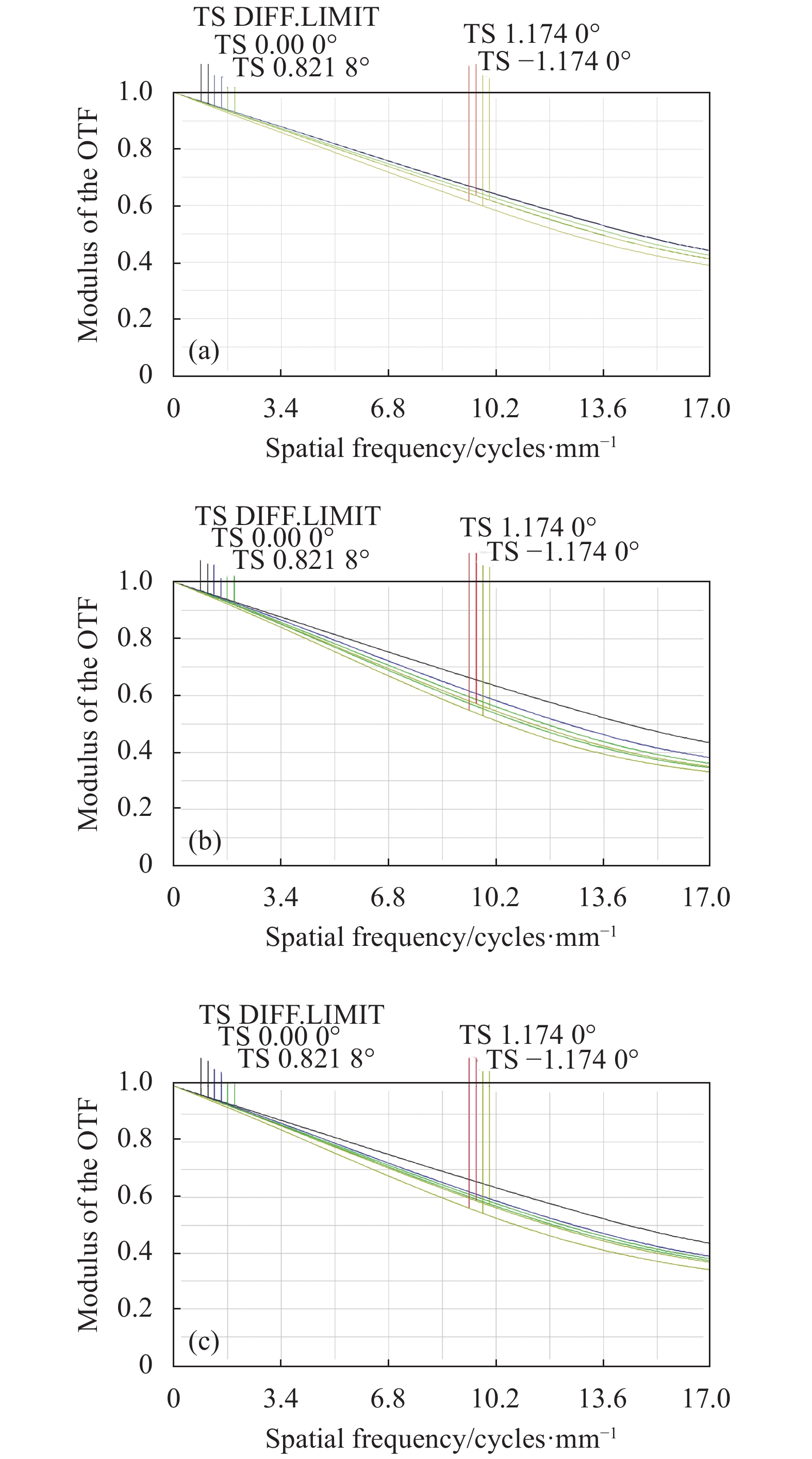

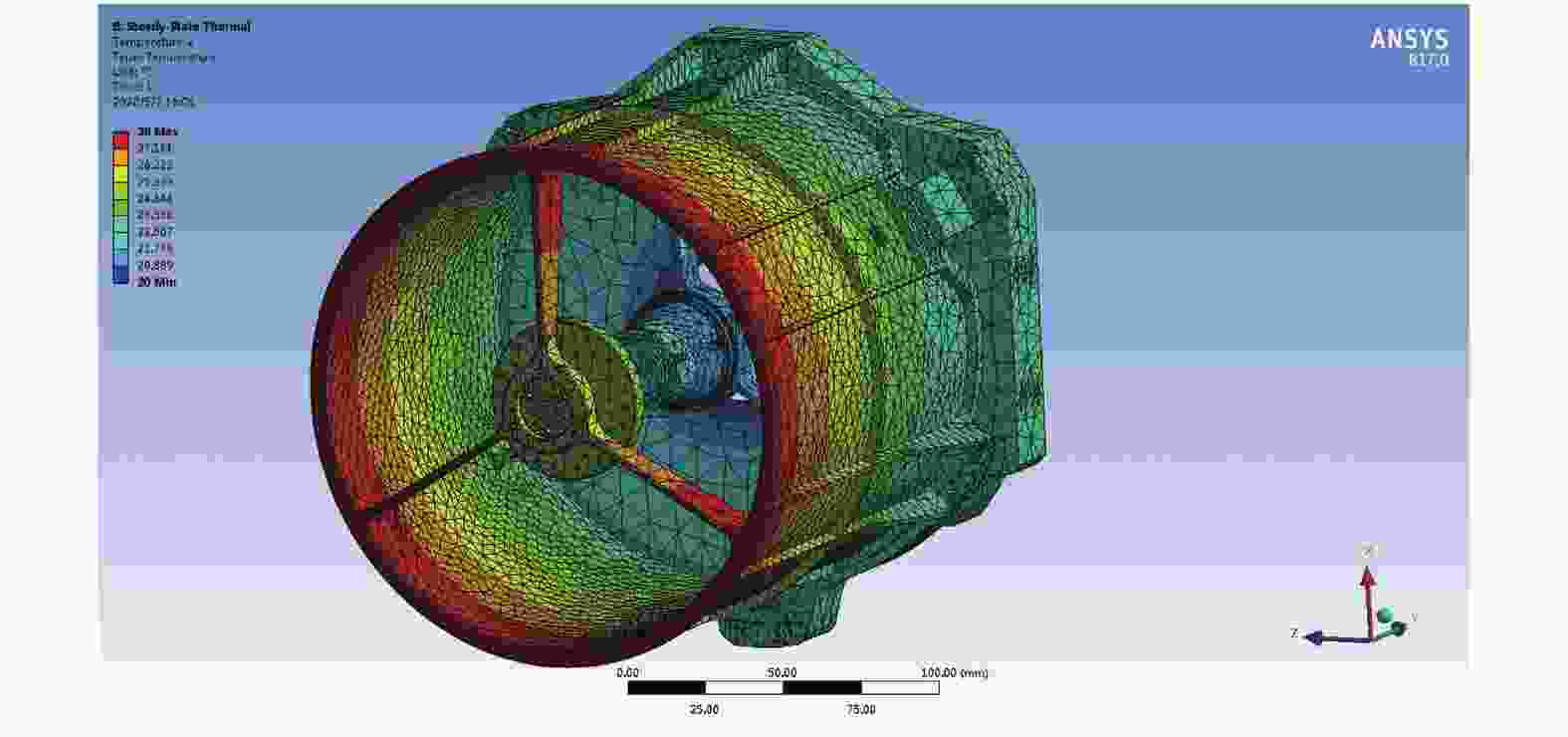

主系统镜坯和相机结构均选择铝,相机质量为1.8 kg (含探测器)。设定基准温度20 ℃,径向温差2 ℃,轴向温差5 ℃,通过有限元进行光机热仿真分析,如图5所示。光学传函在奈奎斯特频率处均大于0.3,如图6(a)所示。此外,软件仿真15 ℃和25 ℃两端温度点对应的传函均大于0.33,如图6(b)和(c)所示。

-

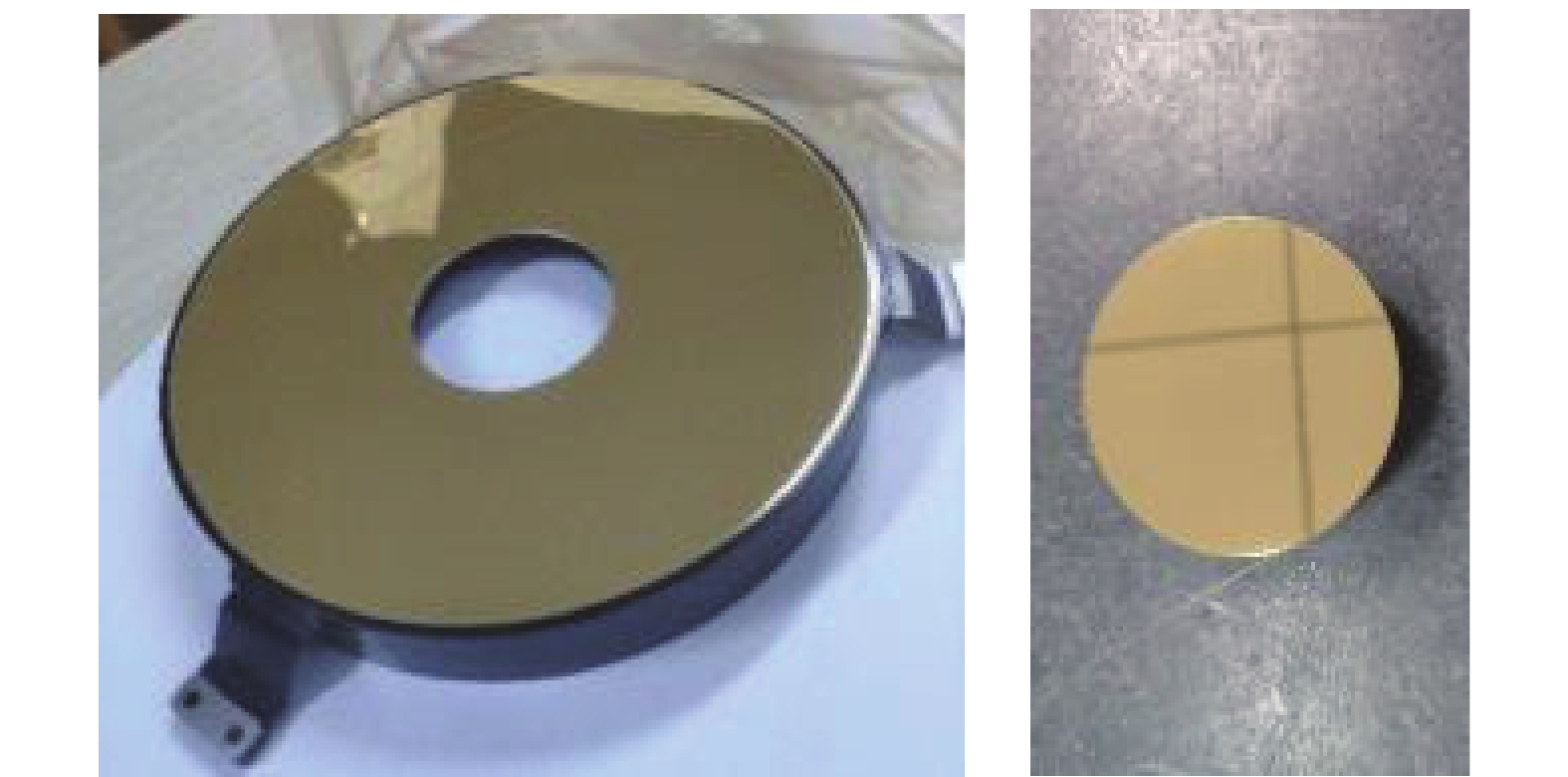

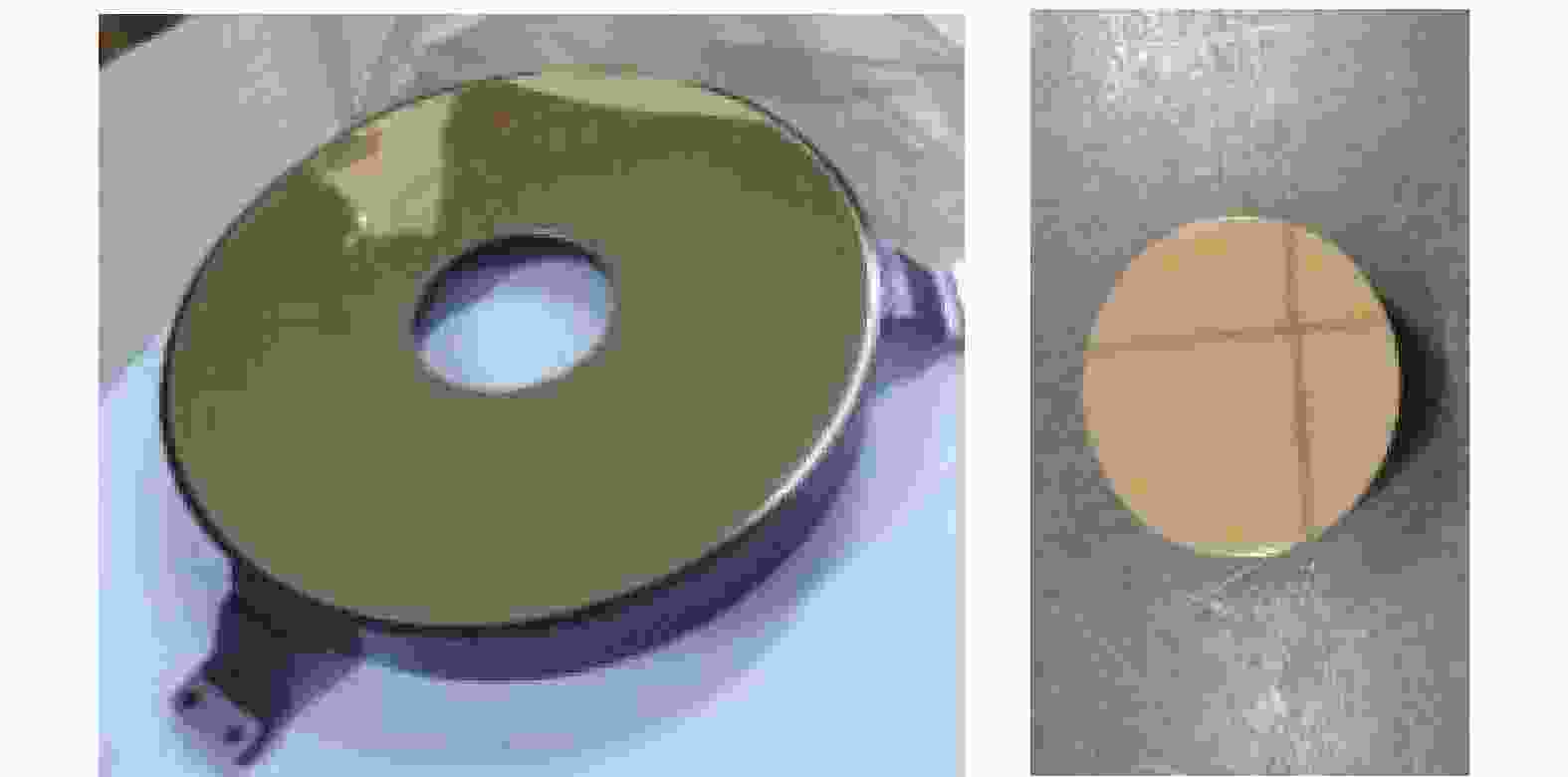

主系统中的反射镜和校正镜组中的透镜,均采用单点金刚石车削技术(SPDT)[12-14]进行加工。主光学中的主镜和次镜,镜坯材质为光学铝T6061,如图7所示,车削后再结合抛光工艺进一步提高面形精度,均优于λ/20@632.8 nm;校正镜组中的透镜,均为旋转对称的球面或非球面,镜坯材质为锗或者硒化锌,口径小的红外材料易于加工,面形精度均优于1/20λ@632.8 nm。

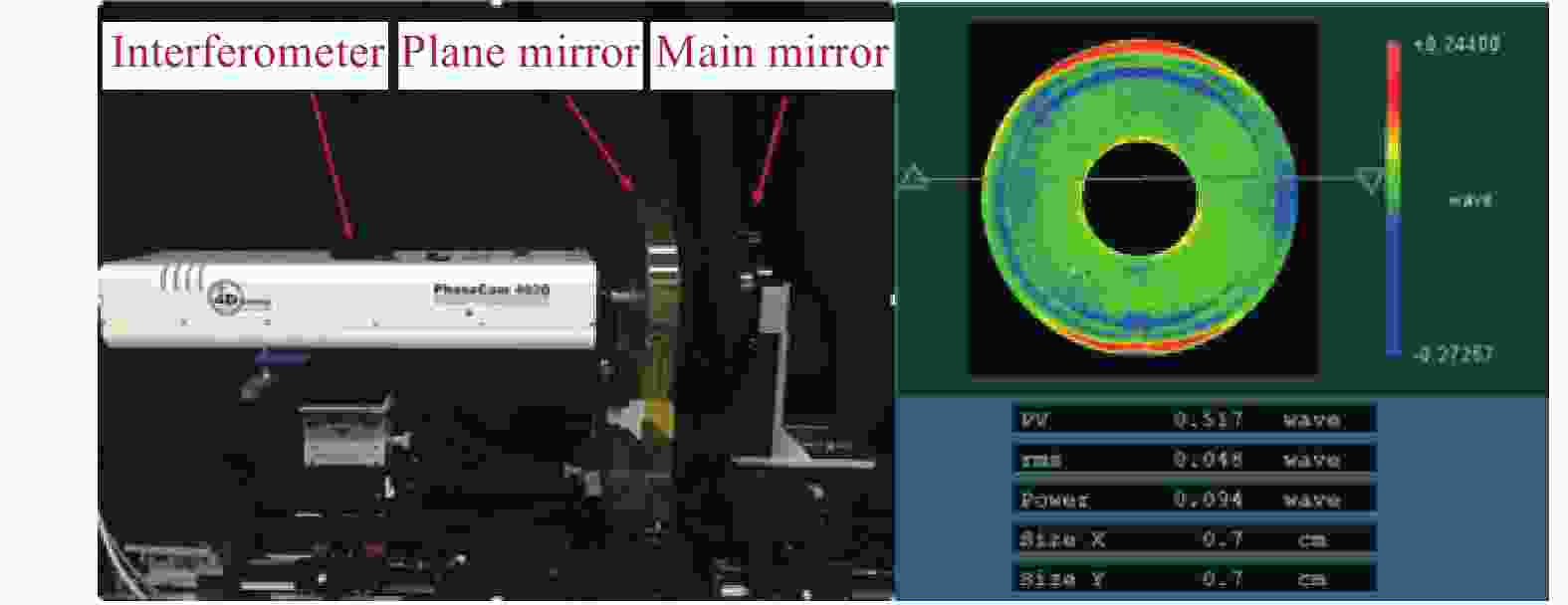

利用干涉仪检测[15- 16]法进行主系统无应力的装调。主镜通过凸耳与主镜背板相连,凸耳通过单点金刚石车削,背板安装凸台通过精研,确保安装面共面度在0.002以内。主镜装配至主系统框架后面形rms为0.048λ@632.8 nm,如图8所示。在主镜安装好之后,由结构加工确保精度,直接安装次镜。校正镜组短且为同轴结构,由光机加工确保同轴精度。

-

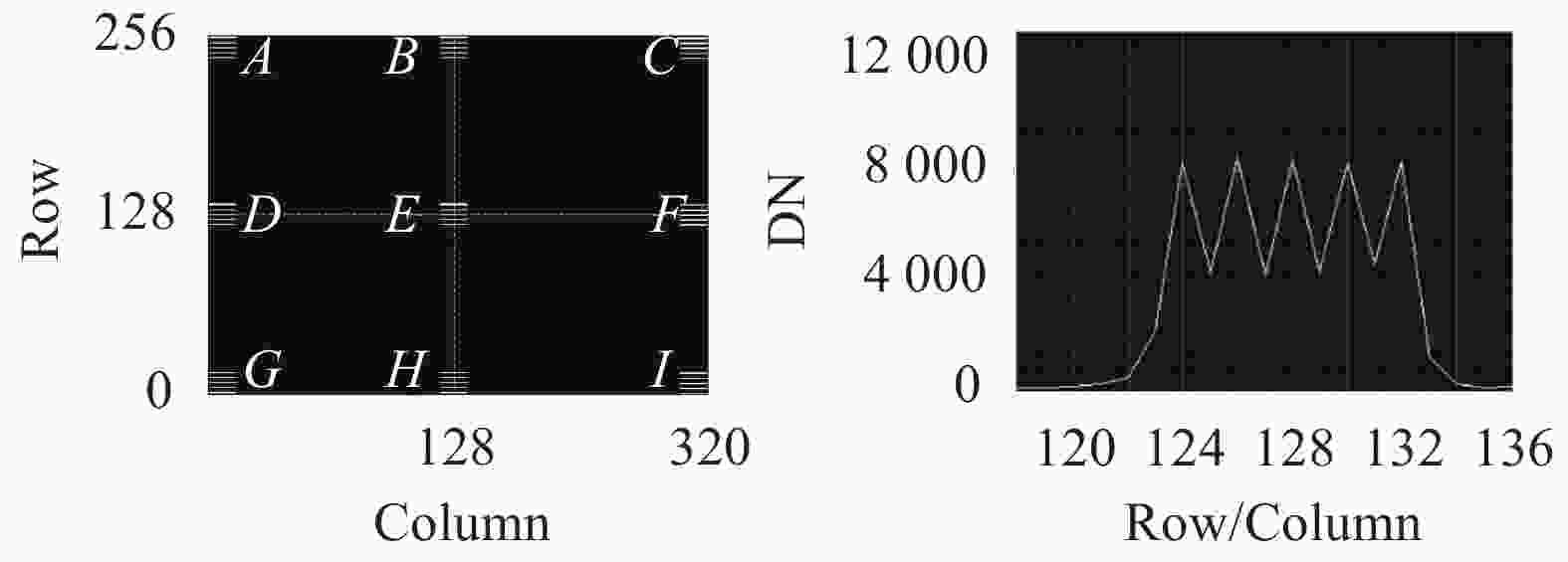

三坐标装配校正镜组至整机框架,系统联调中通过修研垫片实现探测器精准对焦。装调测试平台主要包括2 m焦距平行光管、焦面条纹靶标(理论缝宽0.2 mm,实测略大,约0.23 mm)和转台,MTF界面如图9所示。

全像面选择9点,根据靶标像DN值按公式(7)计算MTF,结果列于表4中,系统MTF(子午和弧矢方向的平均值)优于0.243。探测器传函按0.6计算,考虑狭缝略宽,则系统的光学MTF可达到设计值的85%,在可接受范围内。

Field of view MTF A,B,C A-0.245,B-0.262,C-0.243 D,E,F D-0.259,E-0.267,F-0.248 G,H,I G-0.251,H-0.263,I-0.244 Table 4. Result of MTF measurement

-

系统外景成像实验地点为大楼九楼,实验时间为冬季傍晚。系统成像图如图10所示,景物中的a点为距离2 km外的居民楼,轮廓分明,细节清楚;b点为距离1 km的居民楼管道,尺度约为0.1 m,可以清晰分辨出;成像左下角c处黑点为冬季空调外机,右上角黑色部分为天空。

-

针对无人机载微型光电吊舱的红外探测需求,设计研制了一套面向制冷探测器应用的长波红外光学成像系统。用牛顿式折叠结构代替常用的卡式结构,通过简化主望远镜的结构,在校正镜组中加入非球面来实现较大视场像质校正。主系统采用全铝光机结构设计,全系统光学元件采用单点金刚石车削技术加工,降低了加工装调难度以及研制成本;通过二次成像实现了100%冷屏效应设计,降低了红外热背景,有利于提高系统的灵敏度。该光学系统具有体积小、结构紧凑、像质优良的特点。系统最终装调测试结果表明:像质达到设计预期,满足项目技术指标要求。文中对类似无人机载微型光电吊舱红外探测用的紧凑型红外光学系统的设计与研制,具有一定的借鉴意义。

Design and realization of light and small long-wave infrared optical system

doi: 10.3788/IRLA20200031

- Received Date: 2020-01-17

- Rev Recd Date: 2020-02-08

- Publish Date: 2020-09-22

-

Key words:

- optical design /

- longwave-infrared /

- catadioptric /

- cold stop efficiency /

- light and small

Abstract: The requirements on its load volume and weight are strict for unmanned airborne photoelectric pod. In order to meet the needs of 8-12.5 μm infrared detection, a lightweight and compact long-wave infrared optical system was designed and realized. The F number of the system was 2, the diameter was 150 mm, and the total field of view was 2.34 °. A twice focusing reflection-refraction structure was used as the optical system structure. It simplified the commonly used Cassegrain-type main system into a folded Newton-type main system, and simplified the spherical secondary into a plane mirror folding optical path. The off-axis aberrations were corrected by the aspherical correction lens group. An all-aluminum optical-mechanical structure was designed for the main system, combined with the optical-mechanical material matching of the rear optical path. In the temperature range of the working environment, the designed MTF of the system was more than 0.41@17 lp/mm, with 100% cold stop efficiency, and the volume was only Φ152 mm×125 mm. After final alignment, the MTF of the instrument was more than 0.24@17 lp/mm, and the image quality was clear and met expectations. The optical system was smartly designed, so the structure was light and compact, and the cost of manufacture and alignment was low. The design ideas and development methods can provide a reference for the optical systems of long-wave infrared instruments of unmanned airborne photoelectric pods for similar applications.

DownLoad:

DownLoad: