-

基于掺铥光纤的高性能光纤激光器可广泛应用于频率梳计量、环境传感、人眼安全的激光雷达、空间通信等领域。近年来,随着掺铥石英光纤组分、结构和制备工艺的优化和改善,光纤的掺杂浓度已经有了一定的提升,基于商用掺铥石英光纤已经实现了布拉格反射型(Distributed Bragg Reflector,DBR)短腔单频激光器[1]。但是,铥离子在石英玻璃中溶解度较低,通常需要在石英玻璃中大量共掺铝(Al)等元素来提高铥离子的溶解度,而这些元素的高掺杂会导致光纤的纤芯折射率大幅增加,使得光纤的数值孔径(Numerical Aperture,NA)增大,造成输出激光的光束质量下降。因此石英光纤在高掺杂情况下,通常需要额外的光纤微结构来保证有源光纤的单模特性[2]。

相比于石英玻璃,熔点较低的氧化物玻璃材料具有更疏松的网络结构,可掺杂更高浓度的稀土离子。近年来,锗酸盐、磷酸盐、碲酸盐、硅酸盐等氧化物玻璃材料逐渐被研究人员用来制作高掺杂有源光纤[3]。其中,硅酸盐光纤具有优良的物化特性,例如无毒、不易潮解、较高的机械强度和损伤阈值等。并且,在氧化物玻璃材料中,硅酸盐与石英的结构相似度最高,使得硅酸盐光纤和石英光纤更容易实现高质量熔接,因此硅酸盐光纤有着其他氧化物光纤不可替代的优势。澳大利亚麦考瑞大学的S. D. Jackson课题组和英国南安普顿大学的W. A. Clarkson课题组研究制备了多种掺铥硅酸盐光纤,并用于脉冲光纤激光器[4]、连续波单频光纤激光器[5]、高效同带泵浦光纤激光器[6]等研究中,获得了优良的实验成果。近年来,国内高掺杂硅酸盐光纤及其光纤激光的研究渐成热点,优化玻璃基质的组分和制备工艺,提高稀土离子在硅酸盐基质中的掺杂水平并制作出高增益的有源光纤,具有重大研究意义和应用价值。

目前高掺杂氧化物玻璃光纤中铥离子的浓度通常为5 wt.%,最高掺杂浓度为7 wt.%[3, 7]。文中在已报道的铥离子掺杂浓度基础上,通过组分和工艺优化,进一步提高铥离子掺杂浓度到8 wt.%,探究该高掺铥硅酸盐玻璃的发光特性以及有源光纤的性能。基于研制的新型高掺杂硅酸盐光纤搭建了DBR型光纤激光器,通过2 cm、8 cm的掺铥光纤分别获得了79 mW和166 mW的1950 nm窄线宽激光输出,验证了该国产新型光纤的优良增益特性。

-

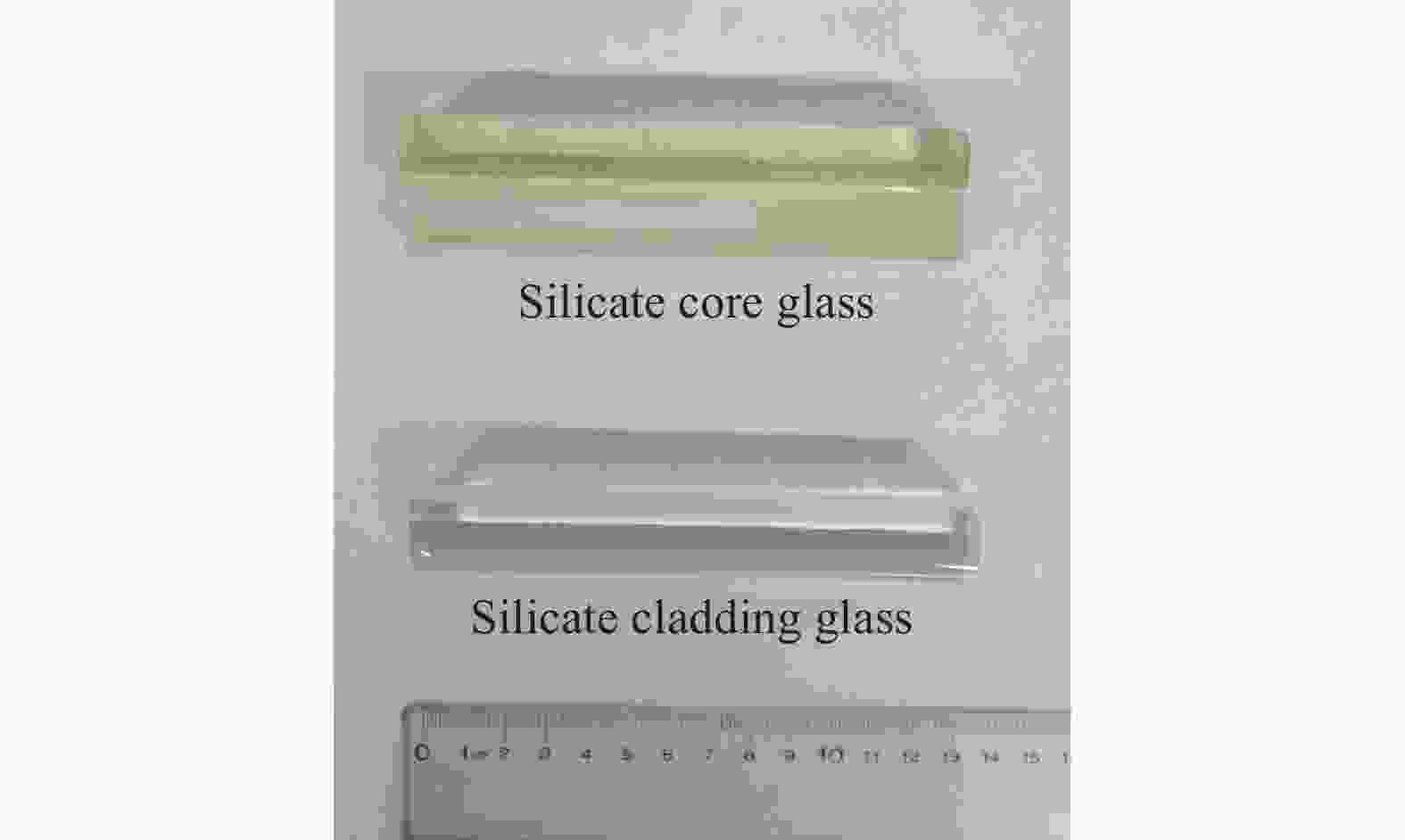

硅酸盐玻璃的摩尔组成为40SiO2−20 (Na2O+K2O)−20 (CaO+BaO)−20 (ZnO+B2O3),纤芯玻璃掺杂的Tm2O3浓度为8 wt.%。选用分析纯的SiO2、Na2O、K2O、CaO、BaO、ZnO、B2O3,以及纯度为99.999%的Tm2O3制备硅酸盐玻璃。所需的化学原料经称量后均匀混合,放在坩埚中随炉子升温至1600 ℃高温熔融,并在高温阶段保温一段时间,随后让坩埚随炉子冷却到1400 ℃,并将坩埚里的玻璃液浇筑在模具上固化成玻璃块,将玻璃块放到退火炉中冷却至室温后取出。制作出的硅酸盐纤芯玻璃和包层玻璃如图1所示,由于纤芯玻璃中Tm2O3浓度较高,玻璃呈现出淡黄绿色。

纤芯玻璃经过研磨抛光,制得尺寸为15 mm×10 mm×2 mm的玻璃试样进行光谱测试和寿命测试。采用Perkin Elmer公司的Lambda-900 UV-VIS-NIR分光光度计可获得掺铥玻璃在500~2 000 nm范围内的吸收光谱,进而掺铥硅酸盐玻璃的吸收截面σa可由公式(1)得到[8]:

式中:OD(λ)代表光密度,其数值可由分光光度计测量结果直接读出;d代表玻璃样品的厚度;N代表玻璃样品中铥离子的掺杂浓度,其计算公式如下:

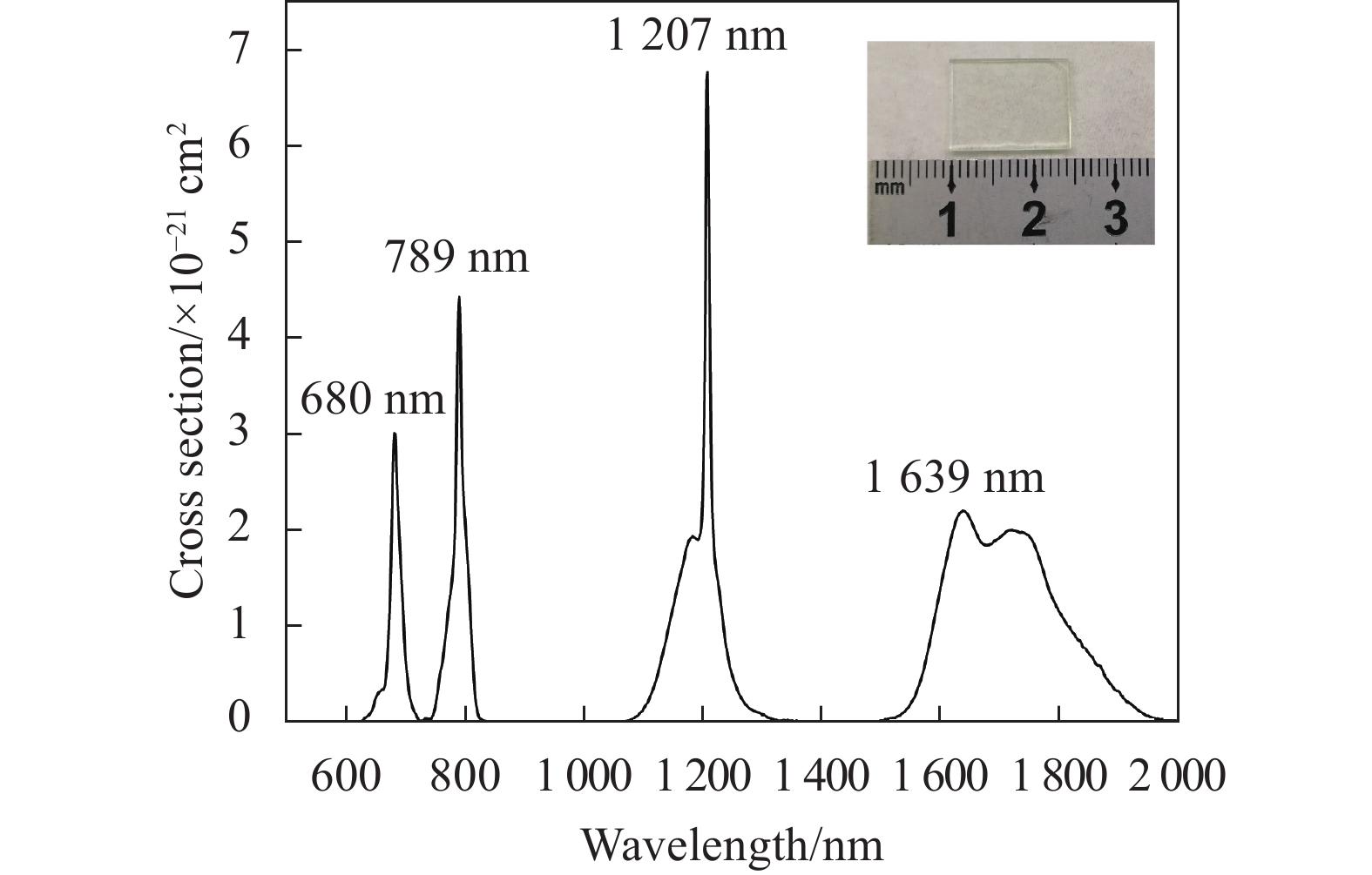

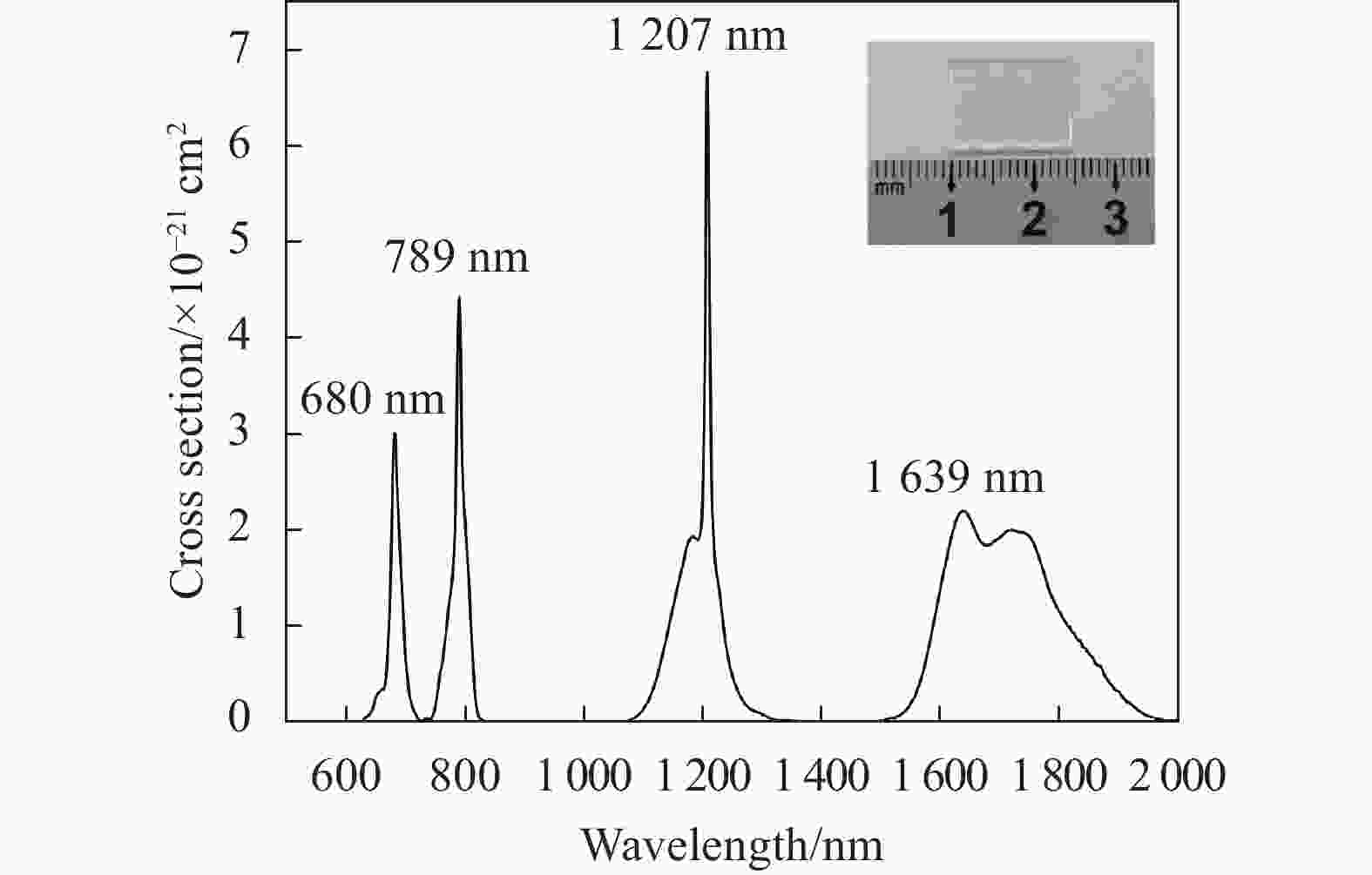

式中:w代表玻璃样品中Tm2O3的质量分数;ρ代表玻璃样品的密度;NA为阿伏伽德罗常量;M代表Tm2O3的摩尔质量。采用排水法测试出玻璃的密度为3.688 g/cm3,因此铥离子的掺杂浓度为8.52×1020/cm3,代入公式(1)可求出玻璃的受激吸收截面,如图2所示。在500~2 000 nm波长范围内观测到四个吸收峰,对应波长分别为680、789、1207、1639 nm,分别对应着铥离子的由基态能级3H6向激发态能级3F2,3、3H4、3H5、3F4的跃迁。玻璃样品在500~2 000 nm范围内的主吸收峰在1207 nm处,对应的受激吸收截面大小为6.8×10−21 cm2,第二吸收峰789 nm处的受激吸收截面大小为4.4×10−21 cm2,这与石英玻璃基质下铥离子在两波长处的吸收强弱有较大差异[9],但符合硅酸盐玻璃基质中铥离子的吸收特性[10-11]。玻璃样品在1207 nm的强吸收峰对应着3H6→3H5的泵浦方式,在利用该波长泵浦时,铥离子3H4和3F4能级的能量上转换效应将导致上能级粒子先后跃迁到3F3,2能级和1G4能级,有望产生800 nm红外光和470 nm蓝光。样品1.6 μm的吸收带呈现出双峰的结构,主峰位于1639 nm,次峰位于1720 nm。在常用泵浦波长1570 nm处,样品的受激吸收截面为0.6×10−21 cm2。

Figure 2. Absorption cross section of Tm-doped silicate glass (Inset: the tested Tm-doped silicate glass)

利用Edinburgh Instruments FLS 980光谱仪测量样品的发射光谱和荧光寿命。选用790 nm激光进行泵浦,测量了样品在1500~2400 nm范围内的发射光谱。根据McCumber理论,在满足稀土离子的能级寿命大于其能级多组态建立热平衡的时间这一前提下,材料的发射截面σe(λ)和吸收截面σa(λ)可以通过公式(3)互相推导[12]:

式中:Zl和Zu分别表示下能级和上能级的配分函数;E0为零线能(即激光下能级的最低能级与激光上能级的最低能级的能量差);h为普朗克常量;c为光速;kB为玻耳兹曼常量;T为开氏温度。上下能级配分函数的定义式为:

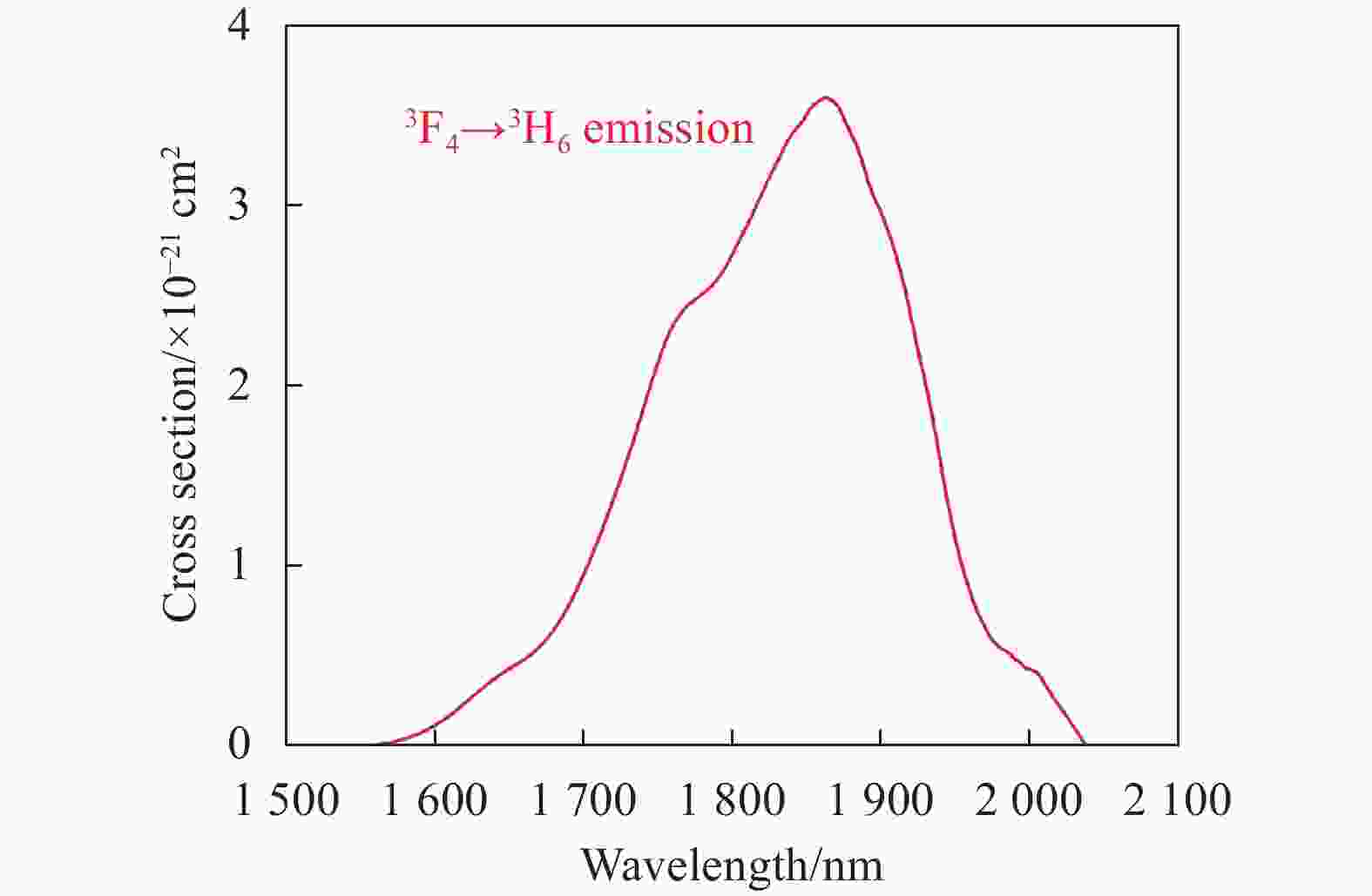

式中:Elj和Euj表示激光下上能级分裂出的各Stark能级的能量。通过玻璃的归一化吸收和发射光谱可计算出E0和Zl/Zu的数值[12],进而计算出样品中铥离子3F4→3H6能级跃迁的受激发射截面,如图3所示。该受激发射截面覆盖了1550~2 050 nm,在1 862 nm处样品具有最大的发射截面3.7×10−21 cm2,与报道的其他高掺铥玻璃的发射截面大小相当[10-13]。

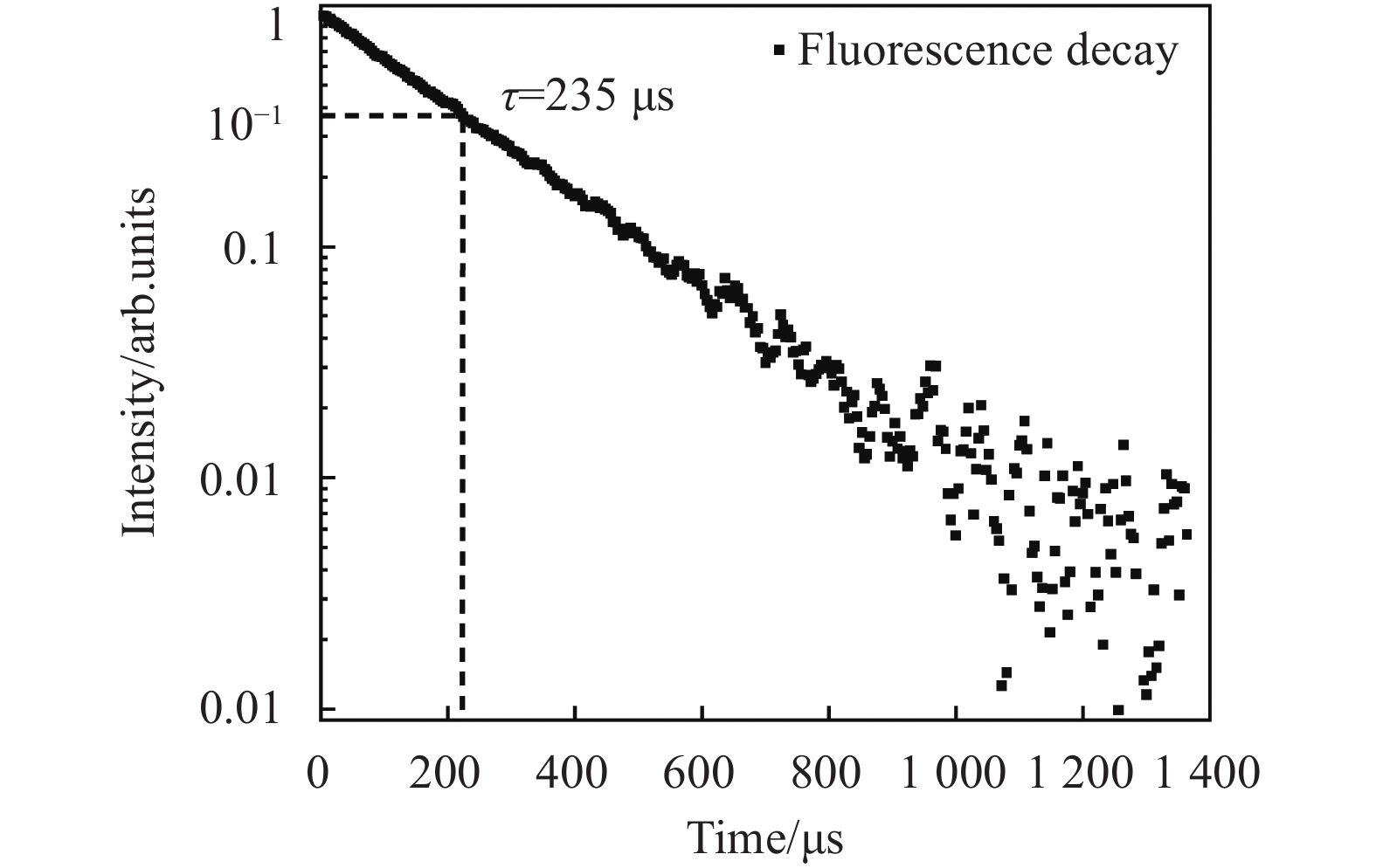

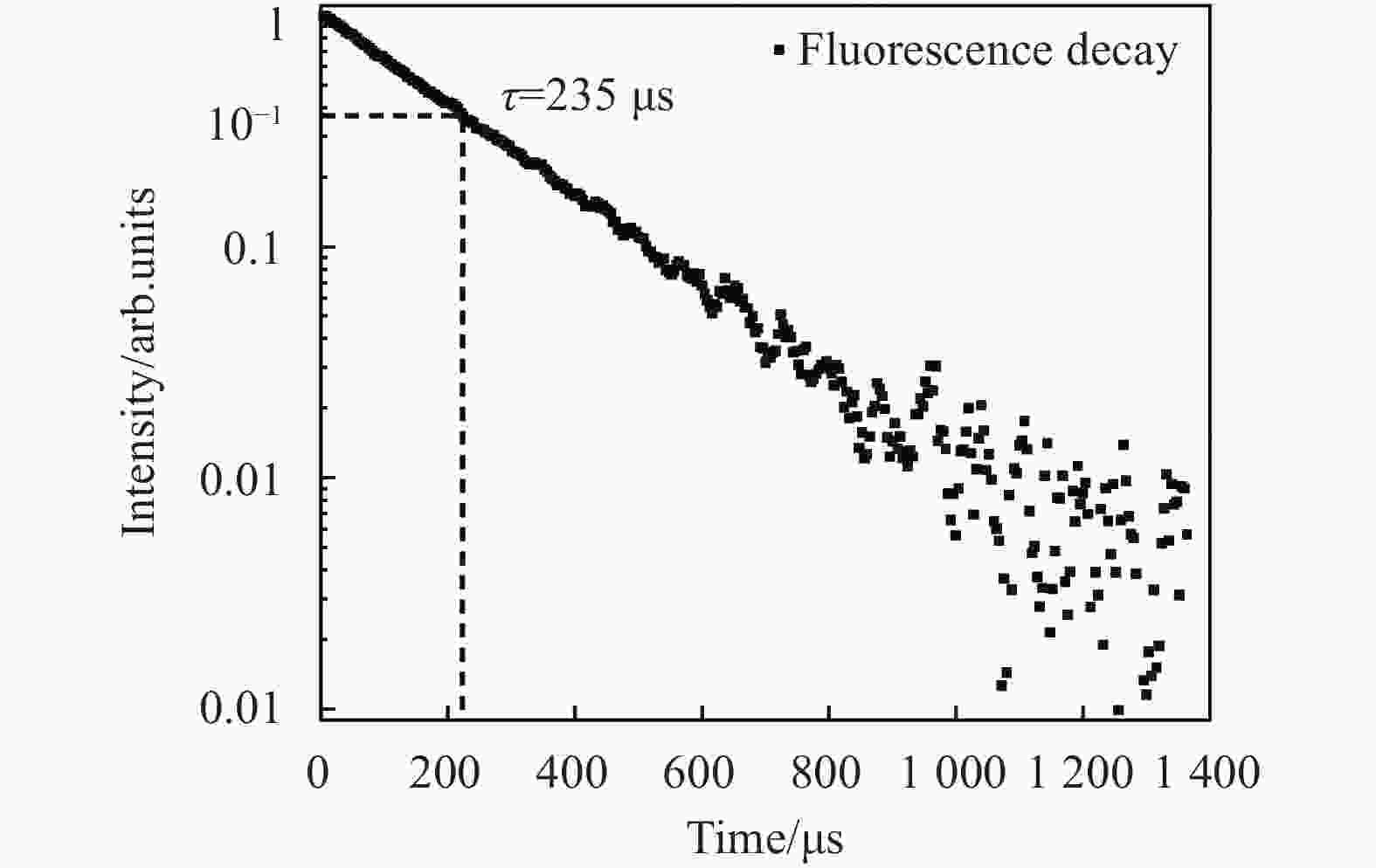

在波长为790 nm的泵浦光激励下,记录了玻璃样品在1 860 nm发射波长处的荧光衰减曲线,如图4所示。当荧光光强衰减到最大值的1/e时,对应时间235 μs即为样品3F4能级的自发辐射寿命,该数值与石英光纤中铥离子的荧光寿命相当[9],但样品具有比石英光纤更高的铥离子掺杂浓度,因此可以实现更高的激光增益。

-

基于8 wt.%铥离子掺杂的硅酸盐玻璃,采用管棒法制备光纤预制棒,并拉制出纤芯直径为7 μm、包层直径为125 μm的掺铥硅酸盐玻璃光纤,光纤端面如图5(a)所示。光纤的纤芯折射率为1.60486,包层折射率为1.59913,NA为0.135。选用Corning公司的SMF-28e+光纤作为掺铥硅酸盐光纤的匹配光纤,两种光纤的参数见表1。利用Vytran GPX-3400光纤熔接平台,采取非对称熔接的方法进行有源光纤与匹配光纤的熔接。图5(b)为利用光学显微镜观察的掺铥硅酸盐玻璃光纤与石英光纤的熔接效果图,图中右侧为掺铥光纤。在泵浦光作用下,熔接点处仅有少量的紫色上转换荧光泄露,说明熔接质量较好,通过进一步测试可知该熔接损耗约为0.6 dB。

Figure 5. (a) End face of Tm-doped silicate glass fiber and (b) the fusion splice of silica fiber and Tm-doped silicate fiber

Parameter Tm-doped silicate fiber SMF-28e+ silica fiber Core diameter/μm 7 8.2 Cladding diameter/μm 125 125 Numerical aperture 0.14 0.135 Effective group index of core refraction @1310 nm 1.4676 1.6049 Table 1. Parameters of silicate fiber and matched silica fiber

基于掺铥硅酸盐玻璃光纤与石英光纤的高质量熔接,搭建了掺铥光纤放大器测试新型光纤的增益性能。利用2 cm高掺铥硅酸盐玻璃光纤对功率为1 mW、中心波长为1950 nm的种子源进行放大。记录不同泵浦功率下输出的信号光功率相对于不加泵浦时输出信号光功率的比值,计算出光纤的增益系数为1.7 dB/cm。

-

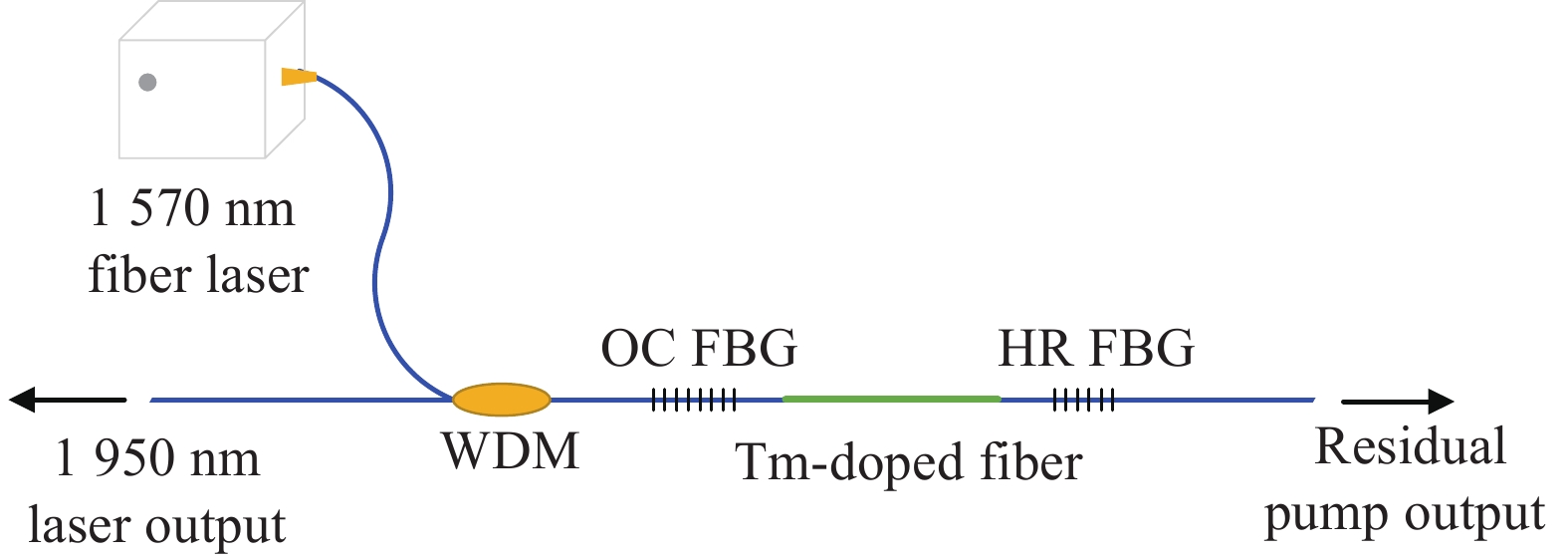

为进一步研究新型掺铥光纤在激光器中的性能表现,搭建了如图6所示的DBR型光纤激光器。采用1570 nm单模光纤激光器作为泵浦源,其输出尾纤为8/125 μm尺寸的单模光纤,最大输出功率为3 W。通过使用反射波长位于1950 nm、反射率为50%的耦合输出光纤光栅(OC FBG)和反射率为99%的高反射光纤光栅(HR FBG)作为谐振腔的反馈元件。其中,HR FBG基于单模光纤(Corning,SMF-28e+)制作,3 dB带宽为0.3 nm,OC FBG基于保偏光纤(Nufern,PM 1550)制作,3 dB带宽为0.05 nm。受到保偏光纤双折射效应的影响,OC FBG在快轴和慢轴方向各具有一个反射带,其中一个反射带与HR FBG的反射带具有相同的中心波长,可以保证腔内仅有单一偏振方向的光谐振。分别使用长度为2 cm和8 cm的有源光纤作为激光器的增益光纤,采用基于保偏光纤的1570/1950 nm波分复用器(WDM)进行泵浦光的耦合和1950 nm激光的输出,未吸收的泵浦光由HR FBG的末端输出。为了避免光纤端面的反射光对激光器的影响,图中的输出光纤均采取角度切割。

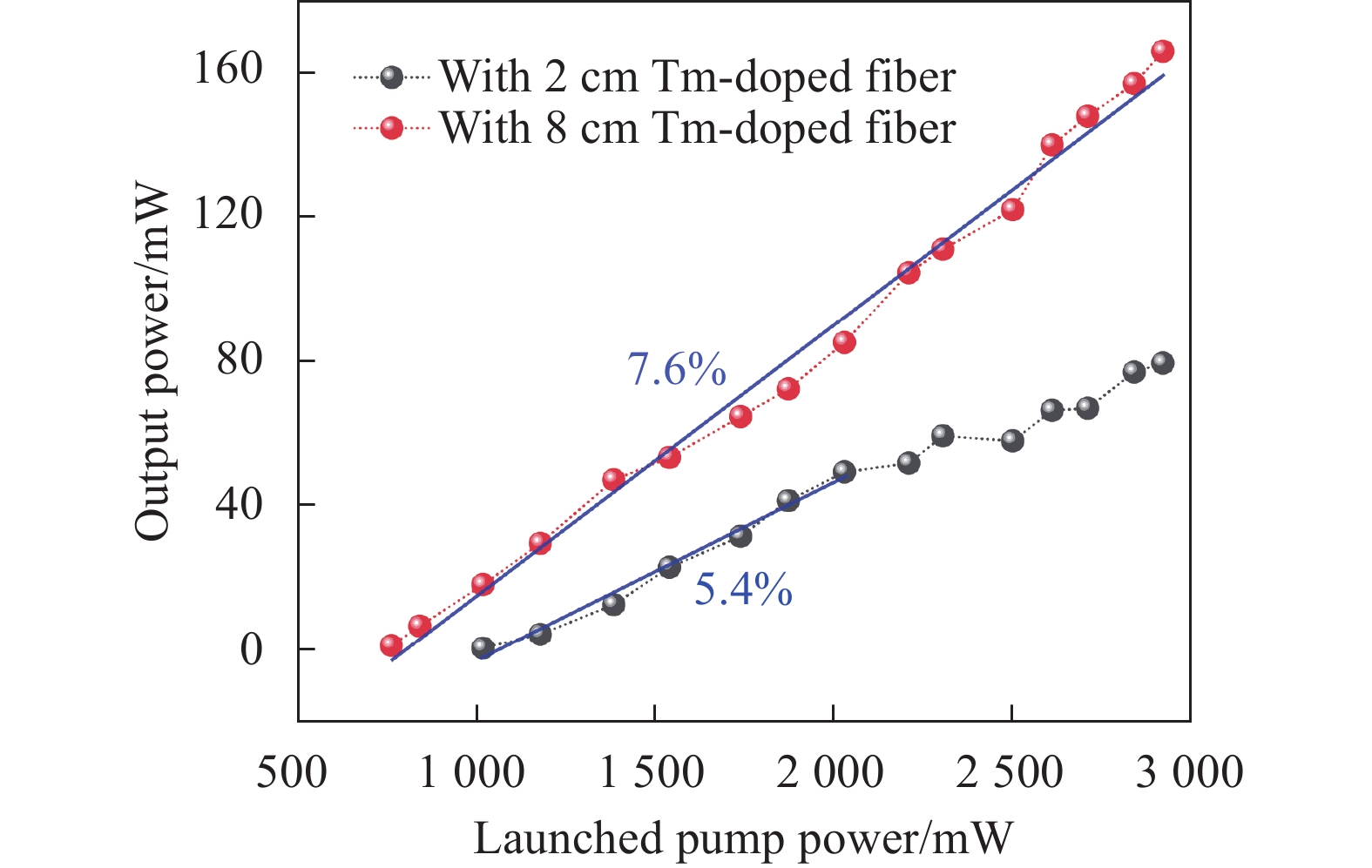

图7为腔内有源光纤长度分别为2 cm和8 cm时激光器的输出功率随泵浦功率的变化关系。当选用2 cm掺铥硅酸盐光纤作为增益光纤时,OC FBG较低的反射率导致了较大的腔损耗,因此激光器具有约1.09 W的阈值。当泵浦功率小于2 W时,激光器的输出功率随泵浦功率的变化呈现出较好的线性关系,拟合可得出此时的斜率效率约为5.4%;当泵浦功率大于2 W时,由于没有施加主动制冷,激光器积累的热效应导致了熔接点的不稳定,因此输出功率有一定的波动;当泵浦功率为2.9 W时,激光器达到最大输出功率79 mW。当选用8 cm掺铥硅酸盐光纤作为增益光纤时,激光器的阈值降为0.76 W,最大输出功率增加到166 mW,激光器的功率曲线具有较好的线性关系,经拟合可得出其斜率效率约7.6%。在2.9 W的泵浦功率下,经过2 cm和8 cm掺铥硅酸盐玻璃光纤的吸收和损耗,剩余泵浦功率分别为1.33 W和0.16 W,说明8 cm有源光纤能够实现泵浦的充分吸收。由于系统中的光纤对于1 950 nm波长的激光均为良好的单模波导,因此激光器始终输出单横模激光。

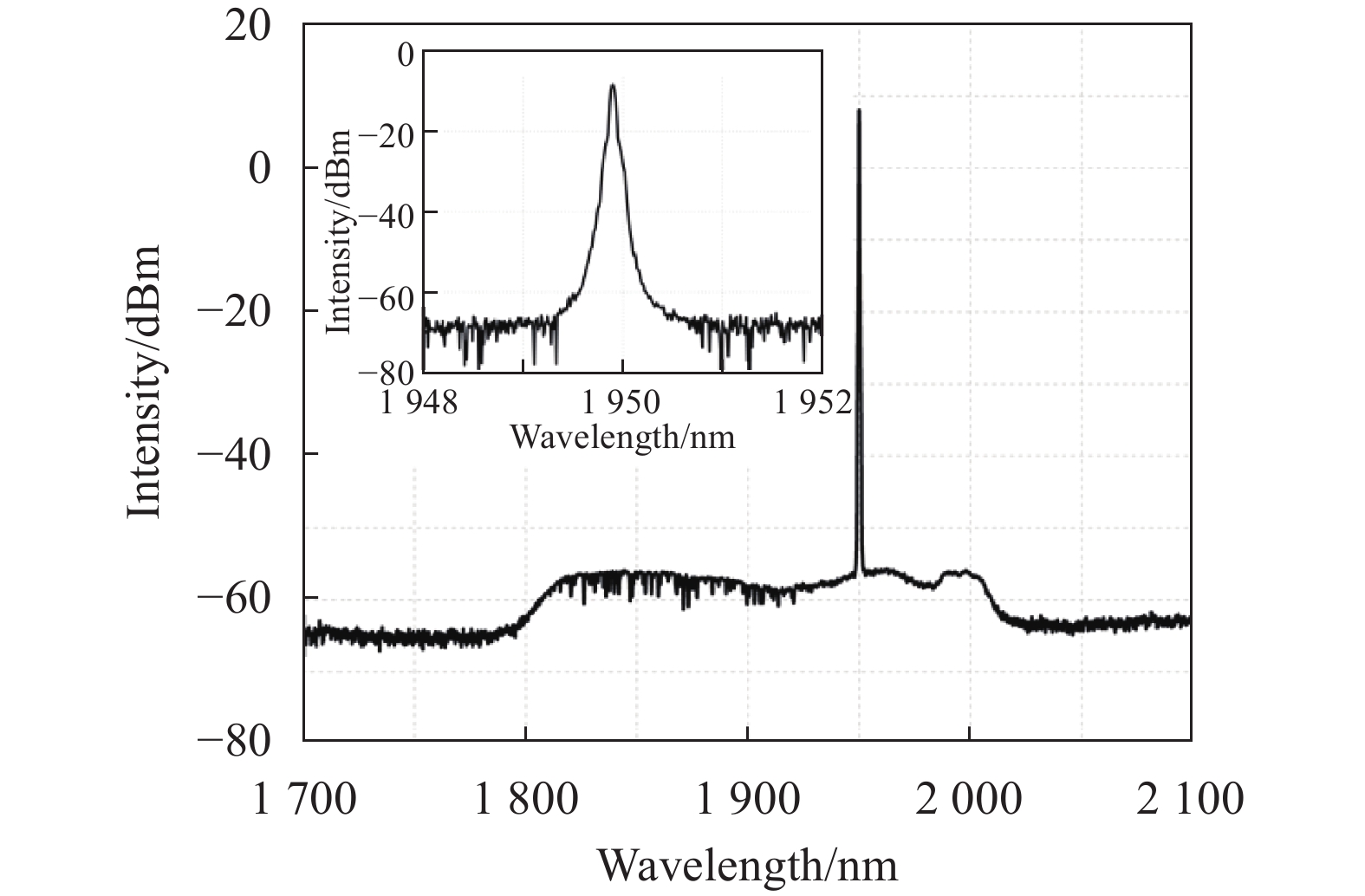

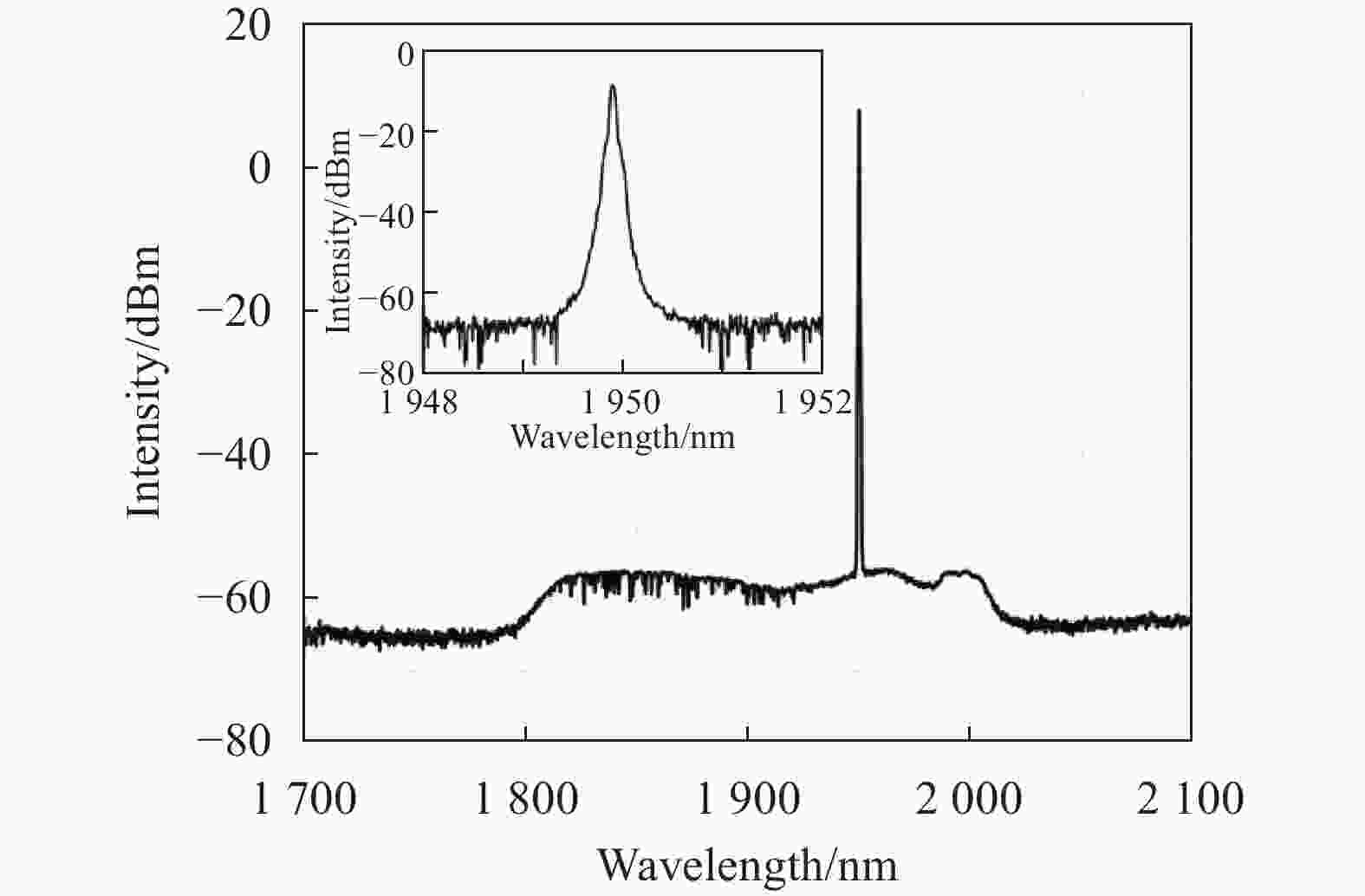

通过Yokogawa AQ 6375光谱分析仪记录了基于2 cm掺铥硅酸盐玻璃光纤的激光器在2.9 W泵浦下的输出光谱,如图8所示。激光器的中心波长为1949.9 nm,最大输出时的信噪比>60 dB,激光的3 dB带宽<0.05 nm,达到了光谱仪的分辨率极限。在后续的研究中,拟选用反射率更高的OC FBG和更短的有源光纤,并充分裁剪光纤光栅的尾纤压缩谐振腔长度,同时对有源光纤实施温度控制,旨在获得稳定的窄线宽单频激光输出。

-

文中对制备的新型国产高掺铥硅酸盐玻璃光纤进行了详细的测试表征,包括激光玻璃发光性能的表征、光纤增益测试以及光纤在DBR型光纤激光器中的性能表现。研究结果表明:掺铥硅酸盐玻璃在789 nm处的受激吸收截面大小为4.4×10−21 cm2,在1570 nm处的受激吸收截面大小为0.6×10−21 cm2,通过倒易法计算出样品中铥离子3F4→3H6能级跃迁的最大受激发射截面为3.7×10−21 cm2 (@1862 nm),玻璃样品中铥离子3F4能级的荧光寿命为235 μs;通过2 cm的掺铥光纤测得其在1950 nm波长处的增益系数大于1.7 dB/cm;基于2 cm和8 cm的有源光纤分别搭建了DBR结构的线形腔光纤激光器,1950 nm激光的最大输出功率分别为79 mW和166 mW。综上可知,该新型光纤具有良好的增益特性,在高性能单频光纤激光系统中具有广泛的应用前景。

Research of novel highly thulium-doped silicate glass fiber and related fiber lasers

doi: 10.3788/IRLA20200424

- Received Date: 2020-11-04

- Rev Recd Date: 2020-12-02

- Publish Date: 2021-09-23

-

Key words:

- highly thulium-doped silicate glass fiber /

- emission cross section /

- fluorescence lifetime /

- linear-cavity fiber laser

Abstract: Active fiber with high rare earth ion doping concentration has always been the key component of high-performance single-frequency fiber lasers, and silicate glass can be used to fabricate highly doped active fibers with excellent unit gains. Here, highly doped silicate glass with the thulium ion doping concentration of 8 wt.% was prepared by a high-temperature melting process, and its spectral characteristics and fluorescence lifetime were measured. Based on McCumber theory, the emission cross section of the glass was calculated. By the method of rod-in-tube, fiber preforms were prepared, and then the highly thulium-doped silicate glass fiber of 7/125 μm was drawn. Based on low-loss specialty fiber fusion splicing, the fiber unit gain was measured, and linear-cavity fiber lasers based on 2 cm and 8 cm novel thulium-doped fibers were investigated, where 1950 nm laser output of hundred-milliwatt-level power was obtained. This work has shown that under such a high doping concentration of 8 wt.%, which is the highest thulium doping concentration to date, thulium ions still have good luminescence properties in this novel glass host. The homemade highly thulium-doped glass fiber in this paper can be used to fabricate high performance single-frequency fiber lasers.

DownLoad:

DownLoad: