-

近十年来,高功率光纤激光器在工业和国防领域的应用举世瞩目[1]。目前,高功率激光器主要由两种途径产生,一种是提升单链路输出功率[2],另一种则是多窄线宽子束合成[3]。两种途径在提升功率输出时都面临增益光纤产生的损耗和热管理的挑战。目前广泛使用的聚合物有机涂层材料存在渗透性强、导热差、热敏感性高(耐热温度小于150 ℃)等缺点[4],极易造成光纤的热损伤甚至损毁。这种高敏感度、低损伤阈值的有机涂层材料不仅限制了光纤的使用环境,同时也极大程度上限制了高功率光纤激光器输出功率的提升[5]。

金属涂层光纤应用在严苛环境的传感器中已有20余年,相较于传统有机涂层光纤,它具有高密封性、高热导率、高热稳定性及良好的化学稳定性等优势,使得它在数百摄氏度的高温环境中仍能正常工作。同时,它还具有磁致伸缩效应、低的声压灵敏度、抗振动干扰等特殊的功能[6],使得其在核工业抗辐射、高温警报系统(火灾等)、光纤温度传感器、耐高温系统、空间环境等应用场景中具有不可替代的作用。

金属涂层光纤常用的制备方法有磁控溅射法、物理气相沉积法和熔融金属冷凝涂覆法[7-9]。其中,磁控溅射法和气相沉积法是将普通光纤涂覆层剥除干净后放入电镀槽或PVD中进行金属沉积,在光纤拉制、剥除、金属沉积过程中不可避免地会导致光纤缺陷的生成,因此此类方法加工的金属涂层光纤机械性能较差且容易折断。此外,此类方法还具有工艺耗时长、工序复杂、且加工光纤长度受限等缺点。而熔融金属在线冷凝涂覆法则是利用刚拉制出的裸纤的冷却作用迅速将熔融金属凝固在裸纤的表面,从而形成金属涂层,由于金属涂层的迅速形成最大限度地防止了光纤缺陷的生成,因此,该方法能加工出机械强度极高的金属涂层光纤。另外,由于该方法是与拉丝塔进行耦合实现的在线连续制备工艺,因此具有生产速度快、涂覆质量好、可批量生产等优点,是制备金属涂层光纤的最佳方法。

熔融金属冷凝涂覆法的核心在于冷凝涂覆装置,装置需要精确控制光纤与熔融金属接触的时间、接触距离和熔融金属的实时温度。目前只有国外少数单位掌握该技术,国内鲜有相关报道。

基于上述背景,笔者所在团队自主研制了在线制备金属涂层光纤的涂覆装置,制备出了形貌良好的金属铝涂层光纤。

-

实验主要采用的拉丝装置如图1所示,装置由石墨加热炉、冷却筒、包层直径测量仪、涂覆装置、牵引轮、收丝装置组成。

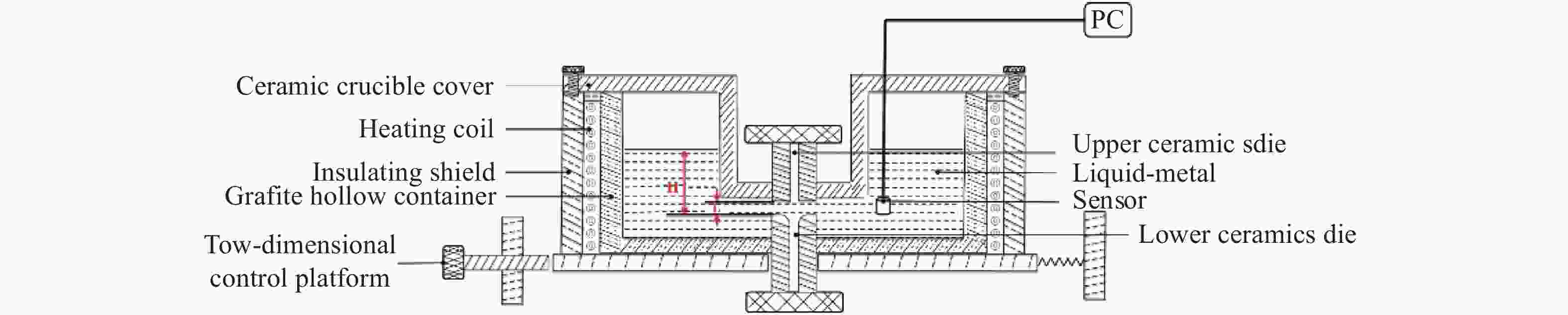

其中金属冷凝涂覆装置主要由温控系统、涂覆系统和惰性气体保护系统三大部分组成,如图2所示。其中温控系统根据设定温度和温度传感器监测值实时调节加热石墨炉输出功率,以实现涂覆装置主体的温度精确控制。惰性气体供应系统则为涂覆装置主体提供惰性气体保护,以防止装置内部液态金属上液面被氧化。

金属冷凝涂覆装置主要结构如图3所示。加热线圈对坩埚持续加热,当加热温度高于涂覆金属熔点时,金属在坩埚内熔化成液体。涂覆模具主要采用耐高温陶瓷材料加工而成。裸纤从陶瓷上模具螺钉中心穿入,穿过并带走液态金属,从陶瓷下模具螺钉中心穿出。由于裸纤的温度低于铝的熔点,故当液态铝接触到裸纤时会迅速降温凝固,形成一层固态铝包覆在裸纤表面,即金属涂覆层。通过旋转模具螺钉可以控制熔融液态金属和裸纤的接触面积,进而控制涂覆厚度和涂覆质量。整个实验装置可以实现液态金属温度以及涂覆接触面积的准确控制,从而确保涂覆质量。

实验采用超纯铝作为涂覆金属原料投放至坩埚中,用石墨高温炉对预制棒进行加热至2100 ℃以上,等高温炉中预制棒达到熔融状态后拉制出裸光纤,将合适直径的裸光纤依次穿过陶瓷上下模具(如图4冷凝涂覆杯所示)。将裸纤绕过牵引轮,并调节牵引速度至裸光纤直径达到合适的直径范围,在调节裸纤直径的同时将坩埚加热至660 ℃以上,直至坩埚内部超纯铝融化成液态铝。待液态铝温度达到稳定范围后,调节陶瓷上下模具螺钉的间距L,控制液态铝与裸纤的接触面积,实现对涂覆厚度与涂覆质量的准确调控。

-

良好稳定的涂覆质量表现在以下几个方面[10]:涂覆层光滑,无气泡或颗粒;涂层直径变化小;涂层均匀,颜色稳定;良好的包层/涂覆层同心度,偏心度小于1 μm最佳。

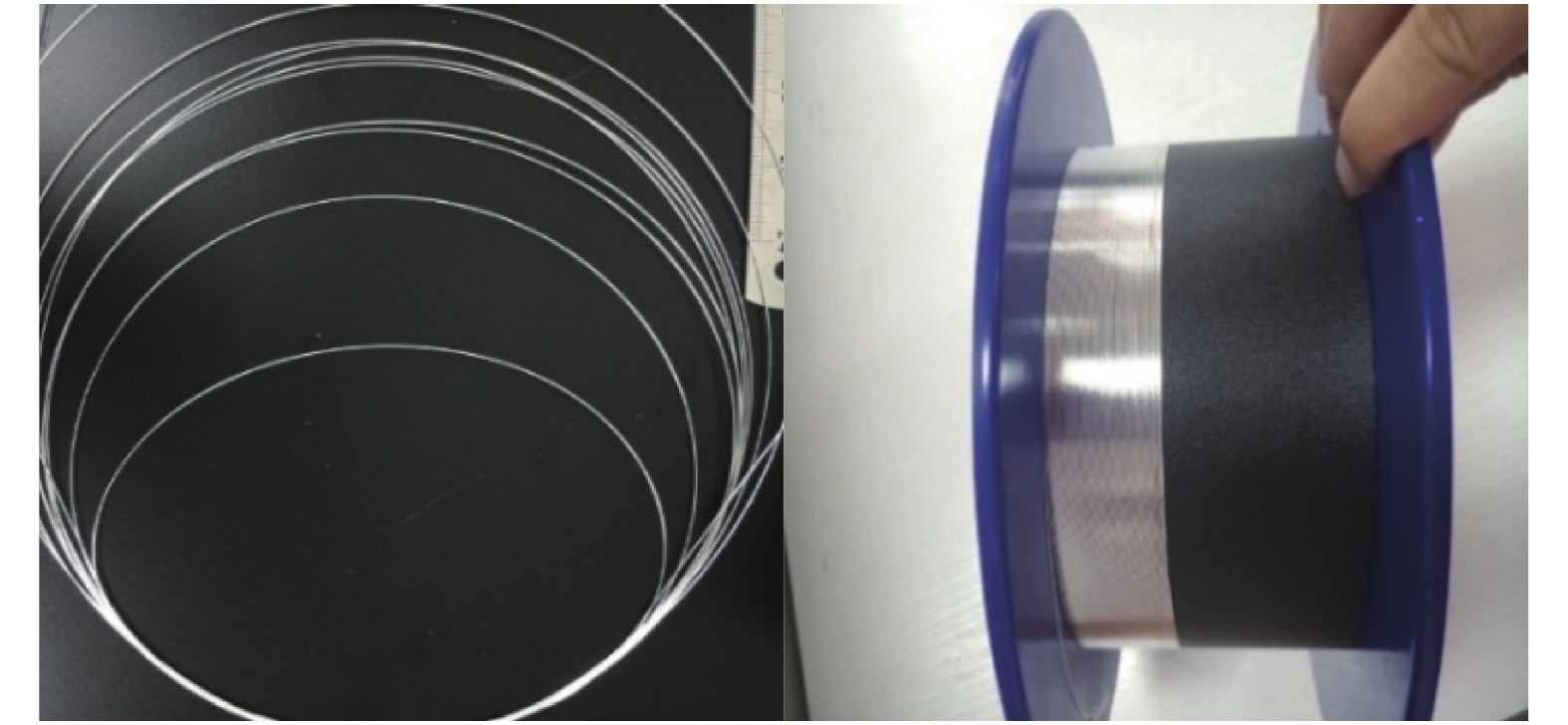

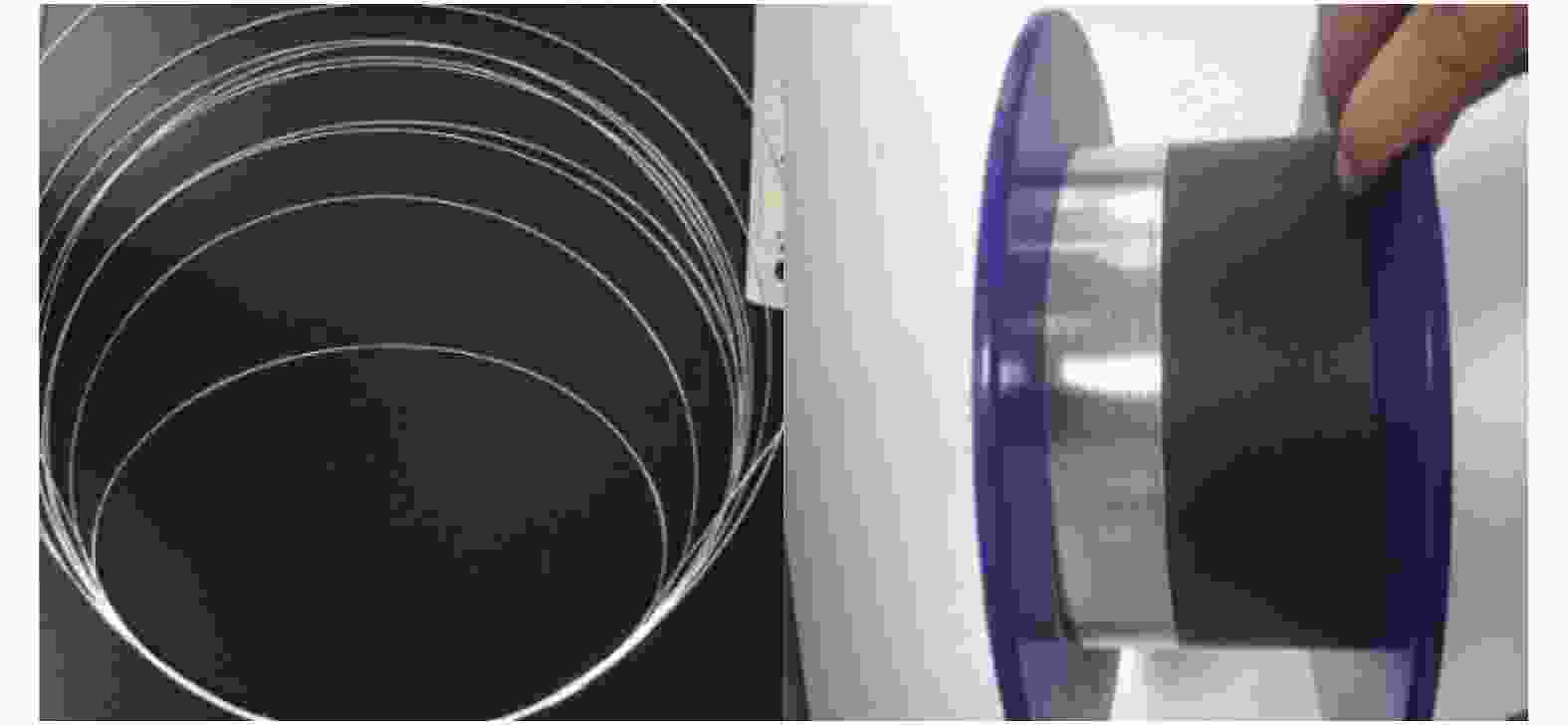

图5为团队采用上述自研涂覆装置进行拉丝涂覆的铝涂层光纤实物。

图6是铝涂层的表面扫描电镜照片。不难发现,在不同放大倍数下,铝涂层表面光滑,无明显缺陷。

Figure 6. Aluminum coating surface under scanning electron microscopy (SEM) with different magnification

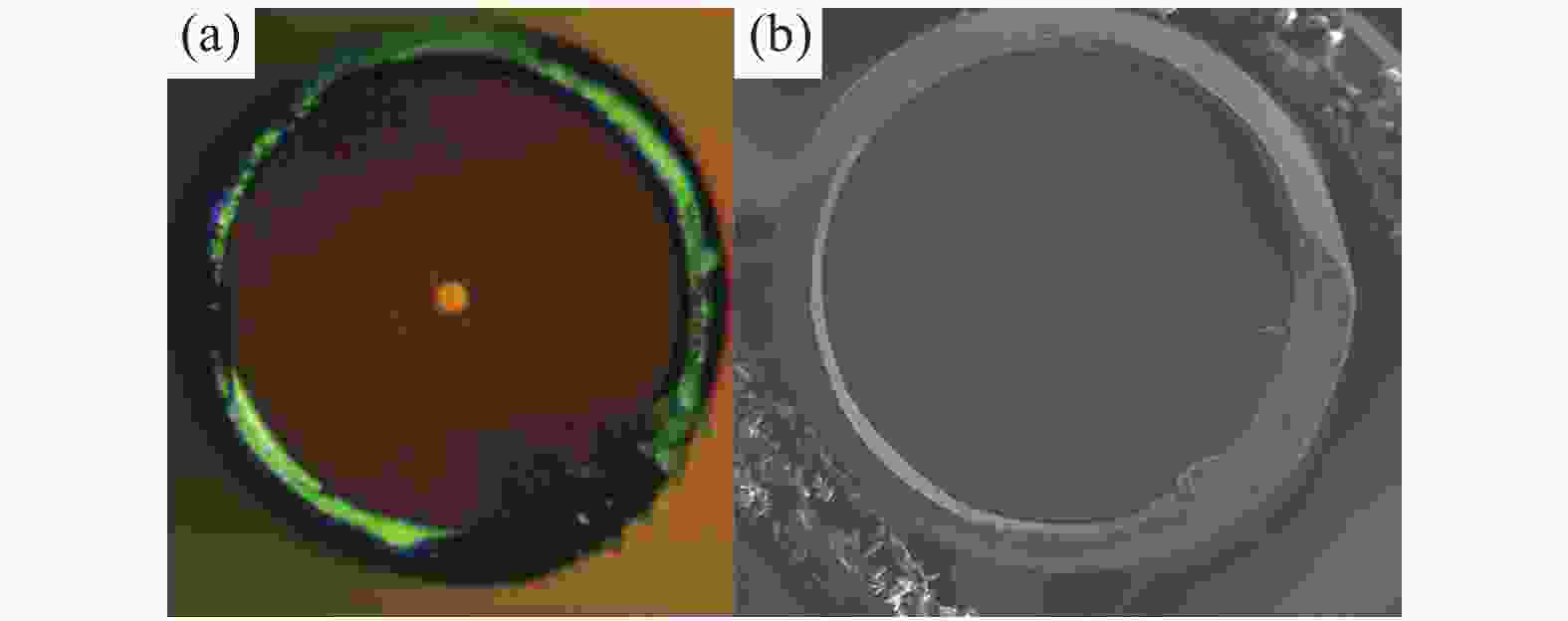

图7是铝涂层光纤在光学显微镜和扫描电镜下的横截面照片。通过扫描电镜测量得到不同方向上的半径尺寸,如图8所示,结果表明:光纤包层/涂覆层同心度良好,涂覆厚度均匀。且通过多次实验发现,在保持坩埚温度、铝液接触面积以及裸纤直径一定的情况下,可以得到涂覆均匀且厚度一致的金属涂覆光纤,工艺稳定性良好。

-

对于金属涂覆光纤,涂覆质量主要受光纤进入熔融铝液的温度T1、铝液的温度T2与光纤和铝液接触时间t的影响。其中铝液的温度T2由系统自由调控,而光纤进入熔融铝液的温度T1与光纤和铝液接触时间t则是由拉丝速度Vf和上下模具的间隙L所决定。

-

金属冷凝涂覆技术的基本原理是金属液体遇冷凝固形成膜层,一般情况下光纤进入熔融铝液时的温度T1与液态铝的温度T2的温差越大,冷凝效果越好。因此,实现金属冷凝涂覆技术的关键技术之一是控制光纤进入熔融铝液时的温度T1,确保T1低于铝的熔点660 ℃。

在线涂覆时,由于光纤在高温炉内拉制成型,其起始温度Ts=2300 ℃。高温炉与涂覆装置间的冷却距离为z,光纤经过z距离自然冷却后温度降为T1。T1计算公式如下:

式中:T1为光纤进入涂覆装置时的温度;T 0为环境温度,T0=20 ℃;Ts为高温炉拉丝温度,Ts=2300 ℃;h为对流换热系数;z为高温炉与涂覆装置间的自然冷却距离;Vf为拉丝速度;ρ为金属涂层的密度;Cp为石英玻璃光纤的比热容;d为光纤直径。

以400 μm直径光纤为例,根据公式计算出了三种拉丝速度Vf条件下的T1与z的关系,结果如图9所示,可以得知:随着z的增大,光纤温度迅速降低。

为了保证良好的涂覆效果,需控制温差T2−T1≥120 ℃。由于T2最低温度为铝的熔点660 ℃,则T1必须小于等于540 ℃。因此,笔者的重点关注20~560 ℃段T1随z的关系变化规律。

结果表明,当Vf分别为10、30、50 cm/s时,对应的最小冷却距离zmin分别为10、32、53 cm。由此可见,拉丝速度越快,所需的冷却间距z越大。需要指出的是,文中装置独特的U型设计可保证实际工况中光纤在涂覆装置入口的温度T1不受坩埚温度的影响,同时也可确保实验数值与计算数值的一致性。

-

以直径为400 μm的光纤为例,实验发现液态铝的温度直接影响金属涂覆层厚度,如图10所示,涂覆厚度与铝液温度呈线性递减趋势。Andrade[11]给出了的黏度μ随温度T变化的半经验公式(2),经许多研究人员证实,该公式与实验值符合相当好。由该公式可知,随着温度的升高,液态金属铝的黏性会下降。因此,在相同拉丝速度的条件下,温度越高,涂覆厚度越小。可以据此调节液态金属铝的温度,进而实现涂覆厚度的精确调控(45~130 μm)。

式中:υ为液态涂层比热容;A,c为常数。

理论上,液态铝温度介于660 ℃与石英玻璃光纤拉丝温度2100 ℃ (铝沸点2327 ℃)之间都可实现冷凝涂覆。但在实际涂覆过程中,若液态铝的温度T2过高会迅速将光纤加热至铝熔点即660 ℃以上,导致冷凝的铝涂层再次熔融脱落。若液态铝温度低至接近熔点,则铝液凝固速度过快,涂覆层会变得不规则甚至凝固过多、过快导致模具堵塞,影响生产。结合实际工况,液态铝温度一般介于630~690 ℃较为合适。

-

上模具内孔处采用平头设计,下模具内孔处采用弧形设计,且二者孔径大小一致。为了避免液态铝向上溢出,要保证液体高度差为(H-L)处的压差作用力小于液态铝的表面张力,因此上模具孔径不不宜过大。

针对不同直径的裸纤,上下模具内径的选择有所不同。原则上来说,光纤与模具之间的空隙越小越好,但不应小于预设涂层厚度,否则模具将损伤铝涂层。另外将装置光纤出口处设计为惰性气体氛围有助于避免凝固后的高温铝涂层发生氧化反应。

-

由公式

$L = {V_{\rm f}}t$ 得知,当拉丝速度Vf一定,L值直接反映了光纤与液态金属的接触时间t。若L过大,则光纤在液态铝中停留时间过长,冷凝后的铝涂层将再次融化,使得涂层厚度太小或脱落;若L过小,则涂层厚度过大或会产生气泡。因此,L值的大小会直接影响涂覆层厚度以及涂覆质量。一般来说光纤与铝溶液接触时间t介于0.1~ 10 ms之间,假设普通光纤拉丝速度约为50 cm/s,则L值为0.05~5 mm。

L值的实际大小可以通过旋转上下模具螺钉来控制,同时需要确保陶瓷坩埚盖的U型底部与坩埚底部的距离大于5 mm。

-

(1) 采用文中所述装置及工艺能够制备出涂覆层光滑、涂层均匀、直径稳定的金属涂层光纤。

(2) 文中工艺适用于石英玻璃,也适用于其他纤维状物体表面金属涂覆涂层的制备。

(3) 在选用其他金属原料时,装置参数会随着不同金属的熔点、粘度、表面张力等物理性质的不同而有所变化,可进一步试验研究。

(4) 文中所述工艺能够实现光纤拉制与涂覆在线连续制备,为金属涂覆光纤的批量生产问题提供了解决方案,为打破国际技术垄断奠定了基础。

Online preparation technology of quartz glass fiber with metal coating

doi: 10.3788/IRLA20210269

- Received Date: 2021-04-25

- Rev Recd Date: 2021-07-30

- Publish Date: 2022-05-06

-

Key words:

- metal-coated fiber /

- molten metal condensation coating /

- online metal-coated /

- fiber laser

Abstract: Compared with the traditional organic-coated fiber, the metal-coated fiber has significant advantages such as high thermal stability and anti-vibration interference. However, the continuous online preparation technology of metal-coated fiber is still in the research and development stage in China, which directly leads to the failure of large-scale continuous production of metal-coated fiber, and to a certain extent, limits the rapid development of high-power fiber lasers in China. An on-line fabrication device of metal-coated fiber based on molten metal condensation coating method was proposed and developed. Coupling with the fiber drawing tower, it can realize metal coating while drawing, and the coating thickness can be controlled. Aluminum coated fiber with uniform coating, good surface quality and stable diameter had been successfully fabricated. The influences of fiber inlet temperature, liquid aluminum temperature, mold aperture and contact distance on the coating quality of metal coating were discussed. By theoretical analysis and practical experiment, the optimum temperature of aluminum liquid is 663-690 ℃, and the linear decreasing relationship between the thickness of coating and the temperature of aluminum liquid was obtained. The relationship between drawing speed and cooling distance was calculated. The optimal aperture size of screw of ceramic upper and lower die and the contact depth between optical fiber and liquid aluminum were given. The research results provide a solution to the problem of mass production of metal-coated fiber and lay a foundation for breaking the international technology monopoly.

DownLoad:

DownLoad: