-

随着红外侦察和制导武器技术的发展,烟幕从传统的遮蔽可见光烟幕发展到对抗红外的干扰烟幕,也推动了国内外新型发烟装备器材的发展,很多国家都相继研发并装备了红外干扰弹药及装备,其中,红外干扰材料一直是烟幕技术发展的重点[1]。选择和制备低毒固体消光材料是实现抗红外烟幕高效和环保的基本要求,也是目前烟幕领域研究的热点问题之一[2]。

碳基吸波材料具有优异的吸波性能,兼有质轻、频带宽等特点,对微波和红外皆有极好的吸波效果[3]。近年来,碳材料基抗红外烟幕研究较多,包括石墨、纳米石墨、炭黑、碳纤维、石墨烯等[4-8]。王红霞等人[9]研究表明,碳纳米材料形成的烟幕在近红外和中远红外均具有很好的消光特性。彭文联、张兴高等人[10]设计制备的纳米石墨基烟幕材料,与炭黑等燃烧产物配合,实现了对可见光、红外的高效遮蔽干扰。刘海清、刘海锋等人采用氧化还原法制备了石墨烯,其干扰性能明显优于现有红外干扰烟幕材料[11]。

然而,单相碳材料往往介电常数较大,损耗机制单一,存在阻抗匹配性较差、吸波频带窄等缺点,因此通常将其与磁性材料复合以实现对电磁波的多重损耗与宽频吸收[12]。例如,CNT/Fe3O4[13]、石墨烯/Co3O4[14]、碳纤维/铁磁金属[15]等复合材料。尖晶石型铁氧体是研究最多的铁氧体吸波材料,其种类繁多。Zn2+很容易取代尖晶石型Fe3O4、CoFe2O4、MnFe2O4铁氧体中部分的二价金属离子,形成含锌的铁氧体[16-18],并且具有较好的吸波性能。将碳基与含锌铁磁性材料复合,使其兼有电阻、磁损耗衰减能力,有望满足质量轻、厚度薄、吸波性能强、吸收频带宽的吸收要求。

文中通过一步水热法制备了多种炭基含锌铁氧体复合材料,并研究了焙烧温度对复合材料形貌、物相的影响。采用傅里叶红外光谱仪的KBr压片法测试并计算了它们的红外质量消光系数,研究了炭基-铁磁体复合材料在红外波段的消光性能。

-

称量适量的炭源、金属盐和弱碱溶于蒸馏水中,搅拌均匀形成橙色溶液,将所配置溶液置于高压反应釜中,将其加热到180 ℃,反应8 ~18 h,最后得到黑色的含碳前驱体的复合固体产物,然后用去离子水、乙醇洗涤数次,置于真空干燥箱80 ℃下真空干燥4~6 h。最后将干燥后的产物置于管式炉中炭化,焙烧条件为氮气气氛、温度为500~900 ℃,焙烧2 h,制备了炭/锰锌铁磁体、炭/镍锌铁磁体、炭/钴锌铁磁体复合材料。

-

用Bruker Equinox-55型傅里叶变换红外光谱仪测定试样的FT-IR光谱;采用HITACHIS-4700的扫描电子显微镜(Scanning Electron Microscopy, SEM)对试样的微观形貌进行表征;试样的物相分析由Rigaku D/max-2500 X射线粉末衍射仪(Cu Kα, λ=0.154056 nm)得到,扫描速率0.02 (°)/s,扫描范围10°~90°。

-

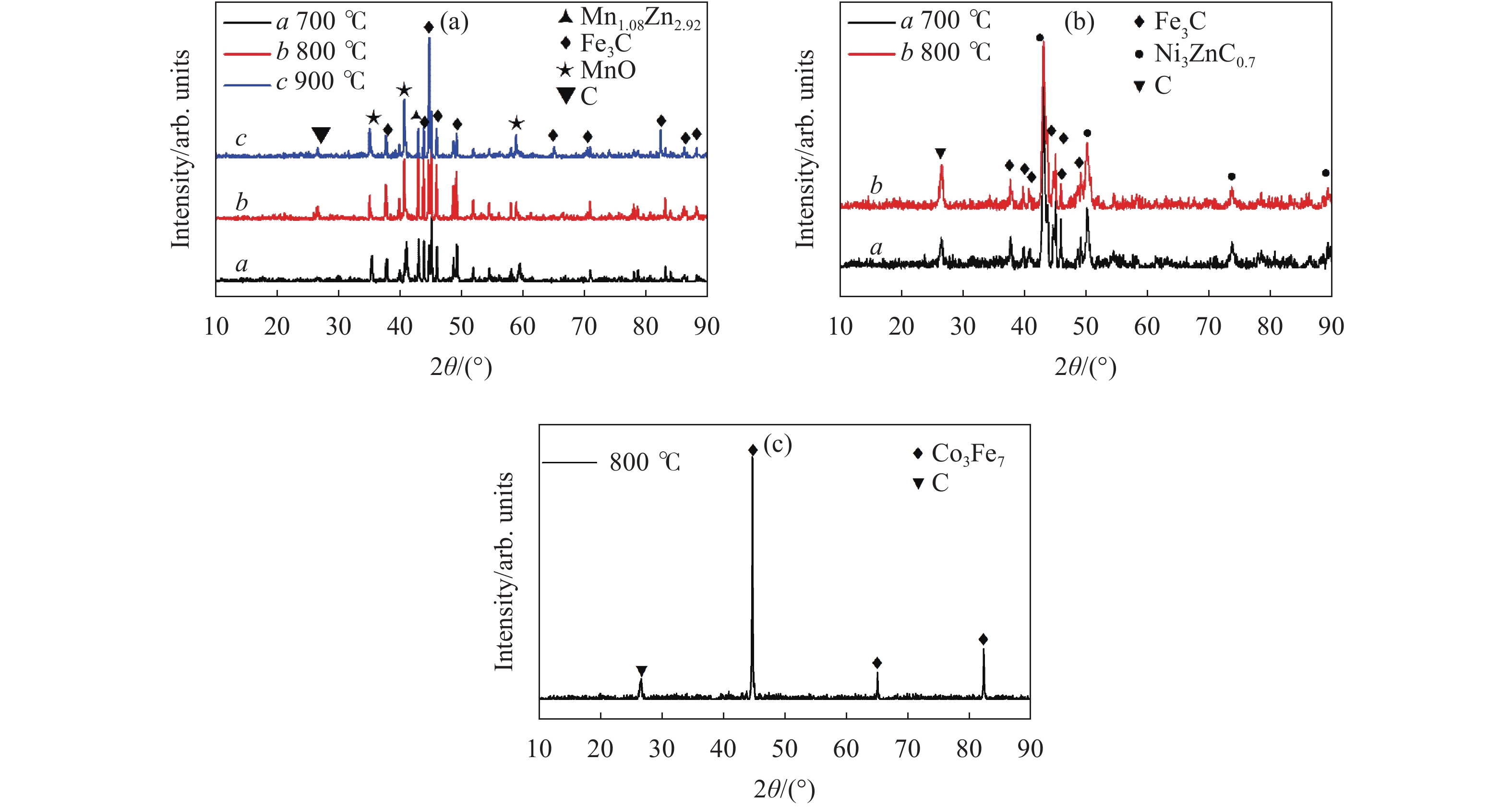

对500~900 ℃焙烧后的产物炭与锰锌/镍锌/钴锌铁磁体复合材料进行XRD分析表征,见图1。

由图1(a)可知,在700 ℃焙烧后,物相检索主要为MnO、Fe3C和Mn1.08Zn2.92三种物相,随着焙烧温度的升高,出现了石墨化的炭峰。由图1(b)可见,700 ℃焙烧后,复合材料由Ni3ZnC0.7、Fe3C和石墨化炭三种物相组成;800 ℃焙烧后,石墨化炭峰的强度增大。物相检索焙烧后的材料中不存在镍锌铁氧体,分析主要是因为焙烧的温度太高,炭源中还原性的基团把铁氧体还原成合金了,同时还生成了Fe3C。图1(c)表明:800 ℃焙烧后主要物相为Co3Fe7,同时还有石墨化的炭生成,分析原因也是在较高焙烧温度下铁氧体全部被还原成了合金。

-

理论上,所有AB2O4型过渡金属的正尖晶石氧化物和反尖晶石氧化物都具有四种红外活性模式,主要有υ1(650~550 cm−1)、υ2(525~390 cm−1)、υ3(380~335 cm−1)和υ4(300~200 cm−1)[19]。由于四面体和八面体配位化合物的固有振动,产生υ1和υ2带。υ1的吸收是由四面体金属离子和氧的键合拉伸引起的,而由于氧气在垂直于连接四面体离子和氧的轴的方向上的振动,观察到υ2振动;υ3模式是从八面体位置的Fe3+-O络合物获得的[20]。

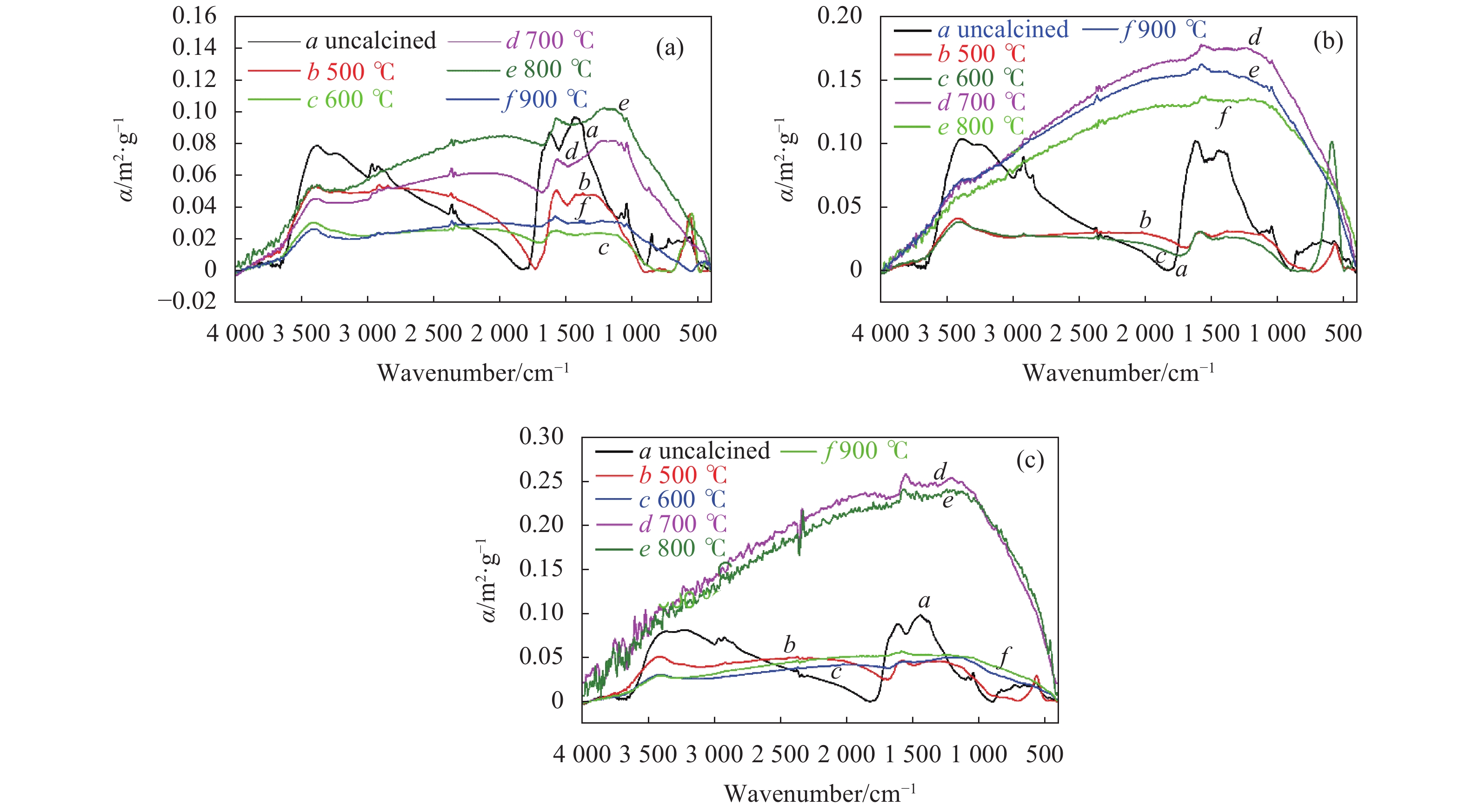

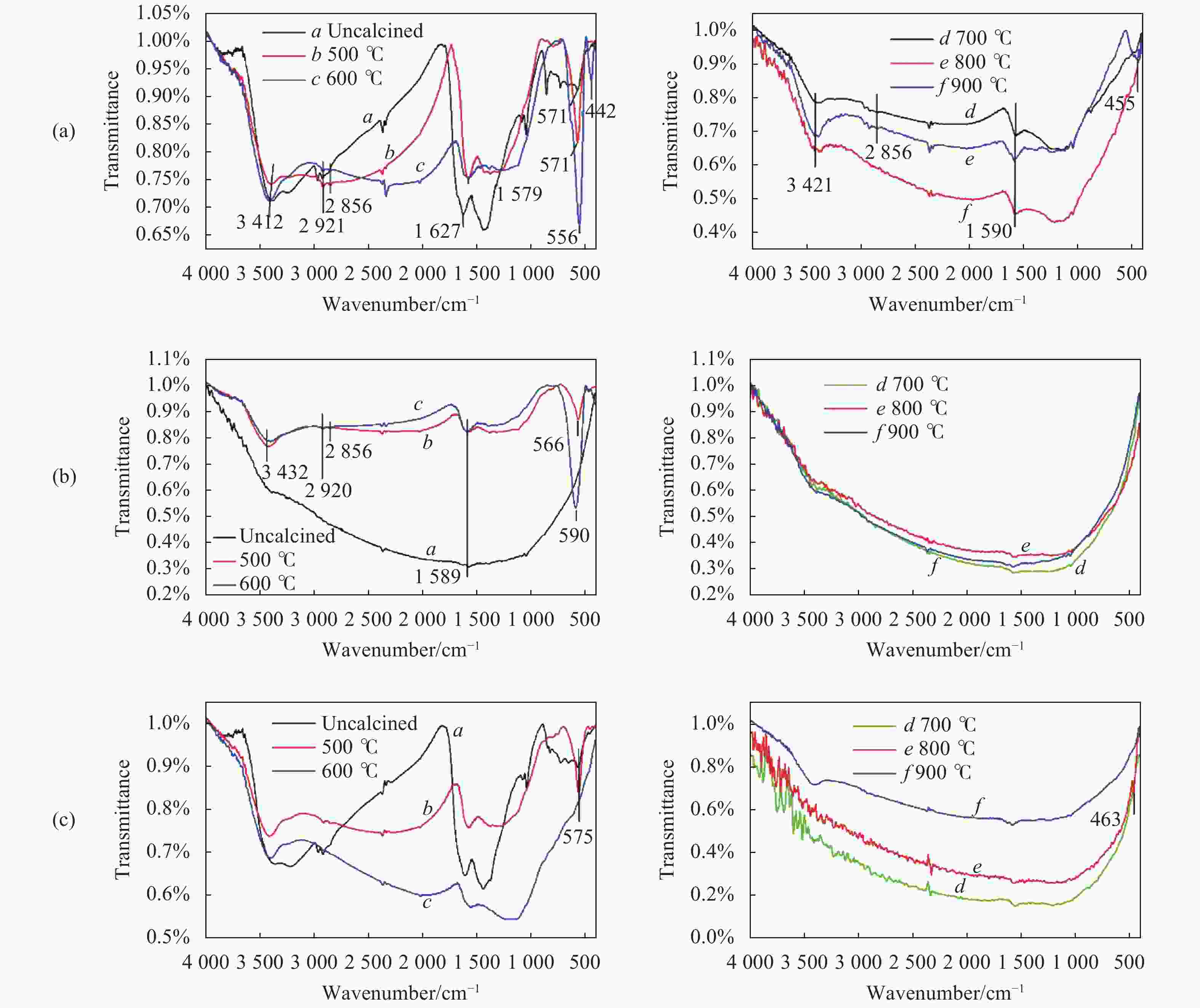

将未焙烧、以及500~900 ℃焙烧后的样品进行傅里叶红外光谱仪测试,测试结果见图2所示。

由图2(a)可见,未焙烧时,样品在571 cm−1处有比较明显的尖晶石型铁氧体的特征吸收峰,500 ℃焙烧后,特征吸收峰增强,提高焙烧温度到600 ℃,在556 cm−1和442 cm−1有明显的峰,随着焙烧温度继续升高,铁氧体的特征峰消失。从红外光谱分析可以得出,600 ℃焙烧条件下,能够形成锰锌铁氧体。结合图1 XRD分析的结果,可能主要是由于700 ℃、800 ℃焙烧时,金属夺取炭源中的氧原子生成了氧化物。

由图2(b)可以看出,焙烧后的产品的FT-IR图发生了很大变化,500、600 ℃焙烧后的产品在580 cm−1附近出现了很强的尖晶石型铁氧体的特征吸收峰,说明焙烧后生成了镍锌铁氧体。700、800、900 ℃焙烧后的样品基本上没有了特征吸收峰,在较宽的波段范围内有红外吸收,同时金属特征峰也消失了,结合XRD分析,可能是由于生成的镍锌合金、Fe3C等对红外没有特征吸收峰。

图2(c)中通过对a~f进行比较可以看出,在焙烧前及500 ℃焙烧后红外谱图中,有尖晶石型铁氧体特征峰,而其他温度焙烧后的FT-IR谱图相似,都没有了特征峰,而且在较宽的波段内对红外有吸收;说明500 ℃焙烧温度有利于尖晶石型钴锌铁氧体的生成,进一步升高温度铁氧体转换成合金。

-

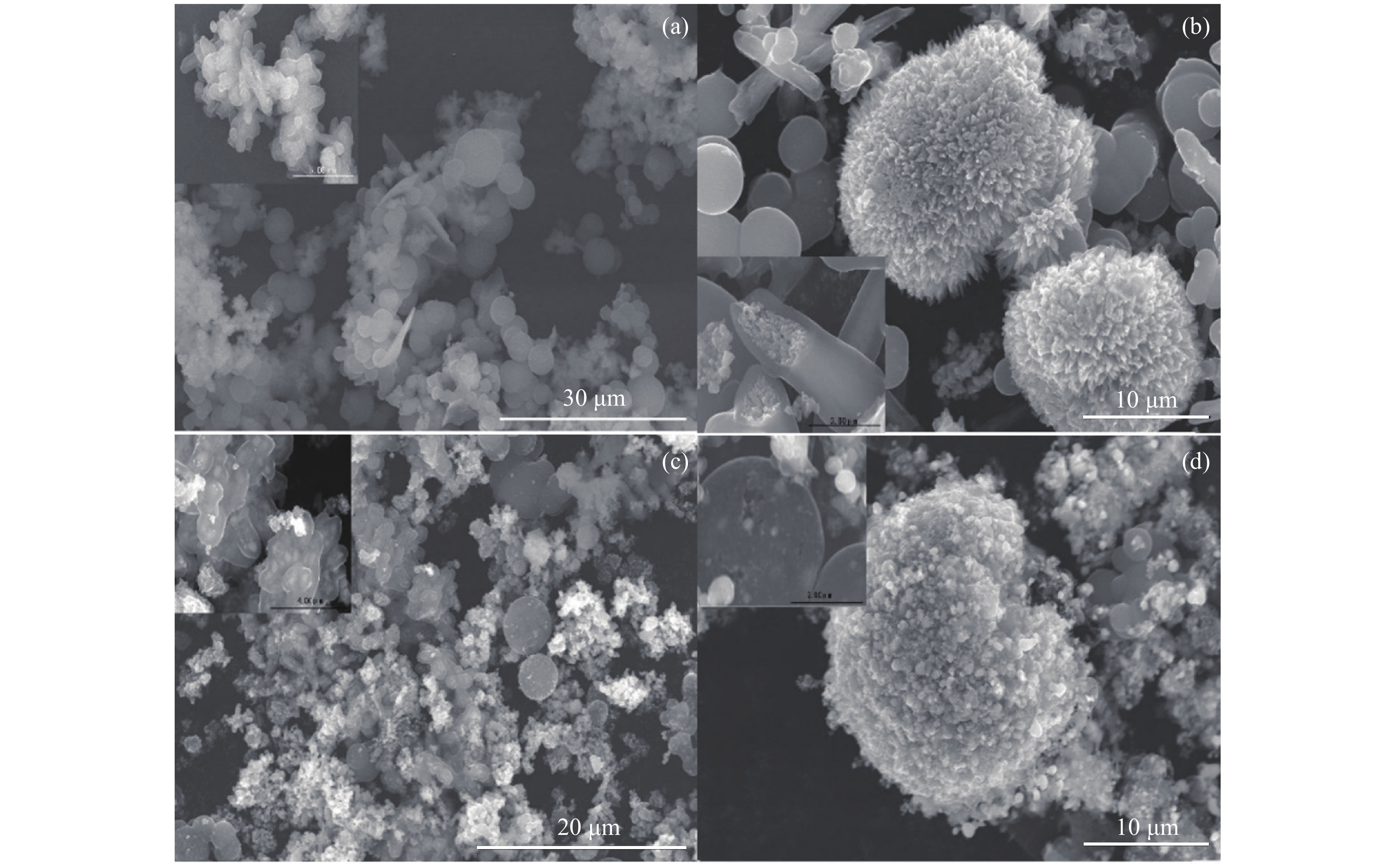

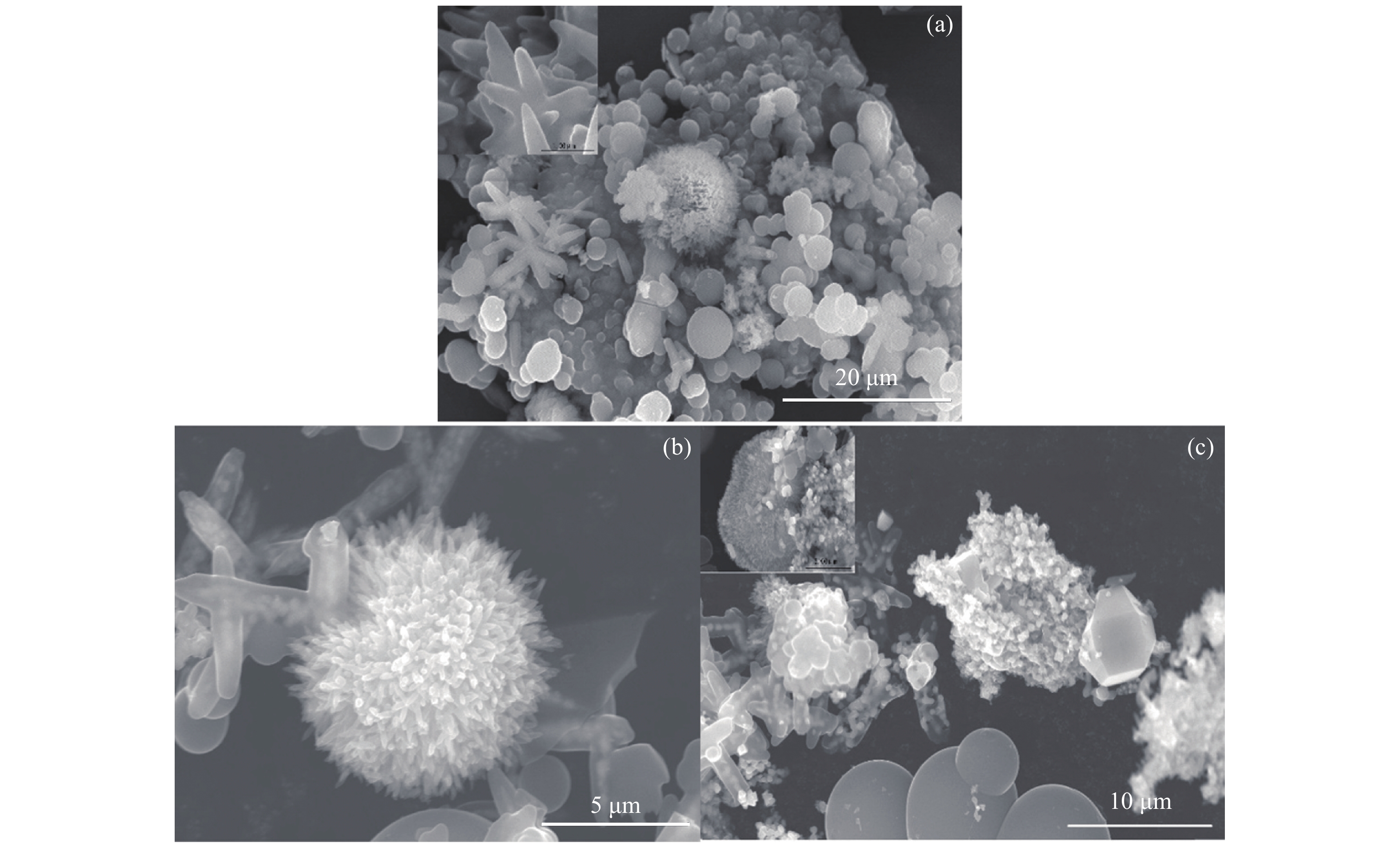

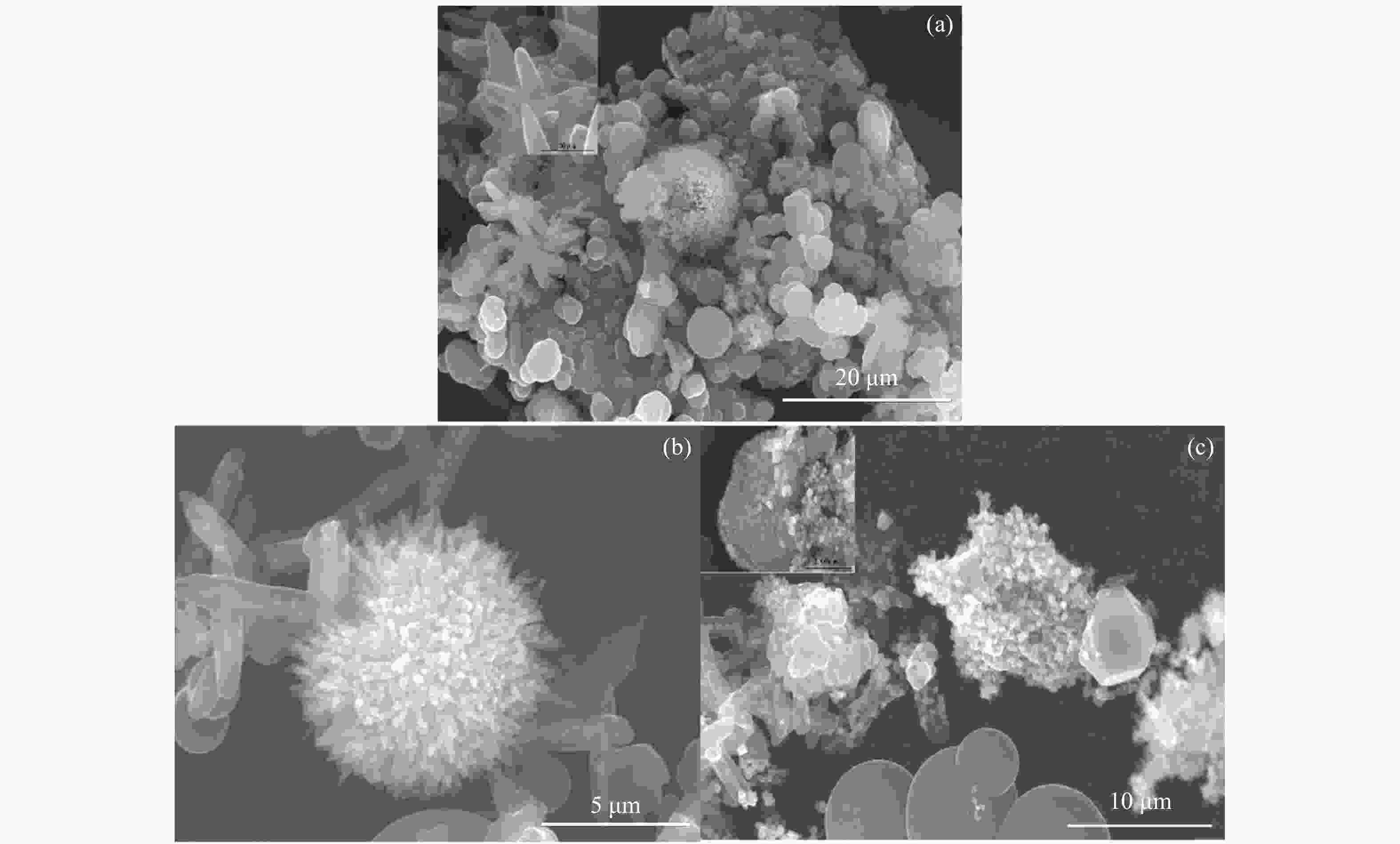

将前驱体和不同温度焙烧后的产物进行SEM分析表征,结果见图3~图5。

图3中,a、b、c分别代表前驱体、500 ℃和600 ℃焙烧后的产物。前驱体中有微米级棒状结构,也有海胆状的自组装体,和游离的碳微球,未在其表面发现异相生成;500 ℃煅烧后,产物逐渐形成了海星状;600 ℃焙烧后,海星状的自组装体又有开始变成棒状的趋势。

图4为复合材料焙烧前后的形貌,其中,a~d分别是前驱体、500 ℃、600 ℃、900 ℃焙烧后,焙烧前产物形貌为团聚的颗粒,还有游离的球形碳前驱体;经过500 ℃焙烧后,除了有光滑的碳球,还有有海胆状的自组装体和棒状结构;在600 ℃焙烧后,棒状结构和海胆状自组装体不存在,又出现了大量团聚的颗粒;经过900 ℃焙烧后,形貌图中出现了大量聚集的颗粒,同时游离的炭球表面出现了孔洞。由形貌分析可知,焙烧温度过高,反而会使得已经形成的微观结构被破坏。

图5为复合材料焙烧前后的形貌图,从图(a)中可以看出,前驱体中存在棒状和海胆状结构存在,并且棒状物质自组装成了海星状,同时还有大量游离的炭球;经过500 ℃焙烧后,海星状结构消失,但是仍然有海胆状结构;600 ℃焙烧后,只存在棒状结构和大量团聚的颗粒,分析是由于碳损耗,颗粒外面的针状物坍塌、烧结形成的。

-

采用傅里叶光谱仪的KBr压片法,定量研究了样品的红外消光系数。根据Lambert-Beer定律计算质量消光系数,公式如下:

式中:α为质量消光系数,单位为m2/g;C为样品的质量浓度,单位为g/m3;L为光程长,指溴化钾压片的厚度,单位为m;I0和I为光通过样品前后的光强,单位为cd;I /I0为红外光透过样品后的光强与透过前的光强之比,即红外透过率。

-

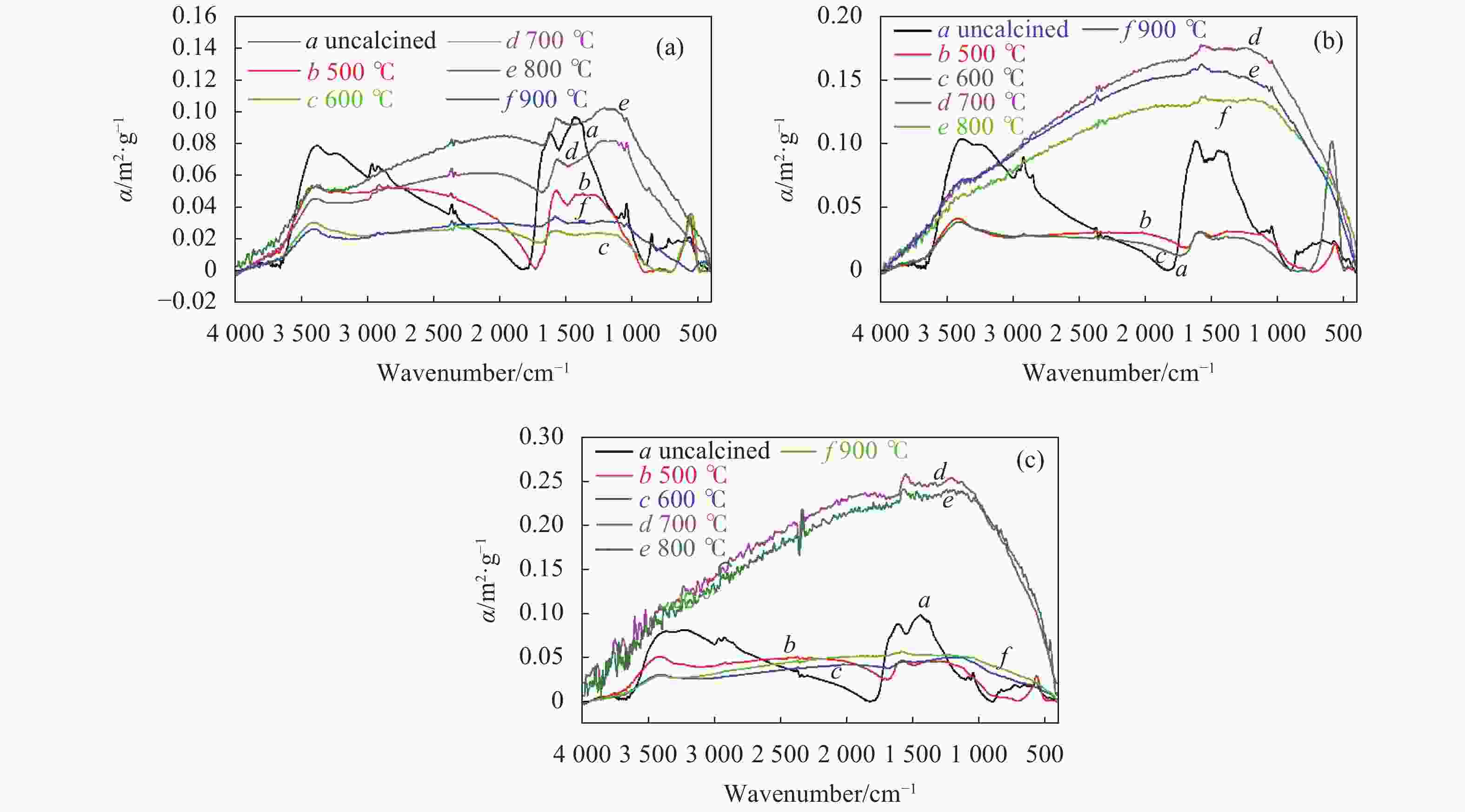

将在500~900 ℃下进行焙烧的炭基锌掺杂铁磁体与未烧的前驱体进行FT-IR测试,并进行红外消光系数的计算,其红外消光系数图谱如图6所示。

从炭/锰锌铁磁体复合材料焙烧前后的红外消光系数,图6(a),可以看出,800 ℃焙烧后复合材料的红外消光性能最大,在8~14 μm波段最大可达到0.1 m2/g,在3~5 μm波段的红外消光系数也比焙烧前的大;从图6(b)炭/镍锌铁磁体复合材料红外消光系数可以看出,焙烧后复合材料在较宽的波段内有较稳定的红外吸收,在8~14 μm波段最大可到0.17 m2/g。从炭/钴锌铁磁体复合材料红外消光系数图6(c)可以看出,焙烧后的复合材料在较宽的波段内有较稳定的红外吸收性能,700 ℃、800 ℃焙烧后的红外消光系数增大,在8~14 μm波段最大可达到0.25 m2/g。根据XRD结果,炭/钴锌铁磁体复合材料的物相是钴铁合金和石墨化碳,而另外两种复合材料含有Fe3C,同时,炭/锰锌铁磁体复合材料中石墨化碳的含量很低,导致三种材料的导电性不同,因此红外消光性能不同;另外,从SEM结果可以看出,三种材料的颗粒大小不同,这也是导致红外消光性能差异的原因。900 ℃焙烧后复合材料的红外消光系数变小,分析是由于高温煅烧后,样品团聚、碳损耗较多造成的。结合材料XRD分析结果可以看出,复合材料经过700 ℃以上的焙烧后,会产生石墨化的碳特征峰,并且700 ℃时,碳材料石墨化的程度适宜,增加材料的介电常数,从而提高了材料的消光性能。当焙烧温度升高到900 ℃,炭化程度过大,碳含量减少,材料变重,单位体积的粒子数减小导致比700 ℃焙烧后的消光性能下降。这一系列变化,主要是随着焙烧温度的升高,材料的物相发生变化,前驱体逐渐碳化脱去氢和氧,并且伴随着石墨化,铁氧体逐渐被碳还原为铁磁体。在物相的变化过程中,材料的电磁性能也发生变化。因此,不同焙烧温度材料的红外消光性能发生变化。

-

(1)通过一步水热法制备了炭基/锌掺杂铁氧体(Fe/Co/Ni)复合材料前驱体。将前驱体在不同温度下焙烧得到的炭基-锌掺杂铁磁体复合材料;

(2)红外分析表明,经过500 ℃和600 ℃焙烧时,能够更好的生成尖晶石型的铁氧体-炭复合材料。提高焙烧温度,会生成石墨化的炭,并破坏铁氧体的结构;

(3)焙烧后,炭基-锌掺杂铁磁体复合材料的红外消光性能均有所增强;在8~14 μm波段,炭基/钴锌铁磁体复合材料在700 ℃焙烧后红外消光系数最大,达到0.25 m2/g;700 ℃焙烧后炭基/镍锌铁磁体和800 ℃焙烧后炭基/锰锌铁磁体复合材料的红外消光系数最大分别达0.17 m2/g和0.1 m2/g。经700 ℃焙烧后的炭基/钴锌铁磁体材料性能较佳,具有潜在的应用前景。

Preparation and extinction properties of carbon/zinc doped ferromagnetic composites

doi: 10.3788/IRLA20210378

- Received Date: 2021-12-25

- Rev Recd Date: 2022-01-25

- Publish Date: 2022-05-06

-

Key words:

- electro-optical countermeasure /

- infrared smoke /

- carbon composites /

- ferromagnet /

- extinction coefficient

Abstract: In order to achieve the high-efficiency and environmental protection requirements of anti-infrared smoke screens, as well as light weight and wide-band wave absorption performance, the precursors of carbon-based MnZn/NiZn/CoZn ferrite composite materials were prepared by a one-step hydrothermal method, and the carbon based/Zn doped ferromagnetic composites were obtained by calcination at the temperature range of 500-900 ℃. The phase and morphology of the compression were characterized by X-ray diffraction(XRD), Fourier transform infrared spectroscopy (FT-IR) and Scanning Electron Microscopy(SEM), and the effect of calcination temperature on material properties was investigated. According to Lambert Beer’s law, the mass extinction coefficients were calculated by KBr pellets method of infrared spectroscopy in the range of 2.5-25 μm, and the effect of calcination temperature on material properties were investigated. The results show that the infrared extinction properties of carbon based/zinc doped ferromagnet composites are enhanced after calcination of carbon based/zinc doped ferrite precursor. The infrared extinction coefficient of carbon/cobalt zinc ferromagnet calcined at 700 ℃ is the largest, which is 0.25 m2/g, and has good infrared extinction properties.

DownLoad:

DownLoad: