-

电气自动化控制广泛应用于工业控制过程中[1],其中自动化装配过程需要在对其装配状态进行检测分析的基础上,才能完成装配轨迹、位姿及力度等实时匹配,从而实现复杂零件的智能化装配。而柔性传感技术可以尽量减小传感单元对装配结构的影响,故基于柔性传感的自动化装配控制技术成为一项新的研究热点。

自动化装配测量设备主要分为接触与非接触两大类[2],接触测量方法通常是将电传感器直接安装于工装等结构上,从而获取装配状态信息[3];非接触测量方法通常是采用激光扫描、拍照等方式对装配路径进行定标[4]。电传感器结构小巧、适合多点组网测试,但易受电磁干扰,而光学扫描与成像的方法灵活性好、精度高,但是测试条件受环境遮蔽条件影响明显,对测试环境稳定性要求也较高。相比之下,光纤传感技术具有体积小、柔性度高、不受电磁干扰等诸多优势,非常适用于各类电子自动化装配控制领域。

基于光纤传感的状态监测研究成为了自动化装配技术的一个重要分支。光纤传感在电气自动化装配的应用主要是对装配过程中结构体应力场、温度场的检测。Esequiel等[5]采用光纤光栅(Fiber Bragg Grating, FBG)传感器对结构滑动状态进行监测,从而为滑动控制提高反馈参数。Arnaldo G等[6]采用将FBG传感器嵌入聚合物中,从而提高了测试稳定性,是一体化测量及控制的新思路。孙宝臣等[7]通过设计新型光纤传感网络布局,实现了结构应力场分布的三维模型构建。刘智超等[8-10]将光纤传感技术应用于智能结构装配,对大型结构装配轨迹优化进行了分析,实验中应变偏差达0.19 mm。肖兴维等[11]采用光纤阵列传感配合光学测量,测试精度可达±30 μm,可用于微小零件装配,由此可见,当变换测试范围时可以有效地对测试精度进行调整。

综上所述,基于光纤传感的柔性智能装配技术在电子自动化装配控制领域具有广泛的应用前景。文中主要研究了光纤传感网络在工业自动化智能装配中的应用,并针对螺钉位姿智能校正问题进行深入研究。

-

测试选用光纤光栅传感器,FBG的反射率决定了回波信号的强弱,其反射率[12]可表示为:

式中:δ表示耦合系数;k表示交叉感知耦合系数;L表示FBG传感器有效长度。

工业自动化控制过程的参数反馈主要是对装配工件上应力的测试,因为装配不当时应力与装配正常时的应力存在大小和方向上的差异,故实时获取应力变化是完成螺钉位姿智能校正的关键。所有获取结构体上的应力分布至关重要。应变就是微小材料承受应力的变形量,当FBG变形时,光栅周期[13]与其关系有:

式中:Λ表示光纤光栅的栅距。FBG的受力分轴向与径向两种,对应的传感特性不尽相同。

FBG选用的材料决定了光纤的弹光系数等相关参数,该参数可认为是常数;泊松比体现了材料变形系数,为常数,则响应波长ΔλB的函数可以写成:

式中:ε为应变;Pε为光纤弹光系数;λB为对应测试FBG的中心波长值。当FBG传感器选定时,则该参数为常系数。

-

由于FBG本身对温度与应变均敏感,所以测试过程中需要考虑温度与应变的交叉敏感问题[14]。在该系统中,由于测试环境的主要应用场合是工厂车间等,所以温度变化差异小,基本可以看作是一个缓变信号,故采用温度FBG标定方式可以实现温度应变解耦。

将温度与应变共同造成的FBG波长偏移表达式写出时,有:

式中:Kε为应变响应系数,由公式(3)计算得到;KT为温度响应系数,由标定测试得到。

测试结构上采用两种不同封装形式的FBG可以同时获得两个信号,一个是采用温度敏感FBG,而结构采用钢制封装,实现不受外界应力干扰,另一个采用塑料封装可以很好地随结构形变而变形。则解耦方程有:

由此可见,由FBG2计算得到的温度变化可以用于对FBG1应变测试的中温度偏差的修正。

-

基于光纤传感的智能装配系统包括了宽带光源、耦合器、传输光纤、光谱仪、FBG等,结构如图1所示。

由图1可以看出,宽带光源作为入射光通过耦合器和传输光纤达到待测位置。测试点上的FBG被固定于装配体结构上,当装配结构发生形变时,形变导致的FBG波长变化会随光纤反射至耦合器,进入光谱仪。光谱仪采集得到的中心波长偏移信号传输至 CPU,经处理器完成对应变值的解算。当获取足够数量的测试数据后,就可以将这些数据作为训练样本进行神经网络学习,从而实现对测试数据的有效分类。

在此过程中,将标定数据库中对温度的解耦补偿参数传给CPU,从而得到准确的应变信息。最终通过应变信息与装配状态数据库完成对螺钉装配位置的校正。

-

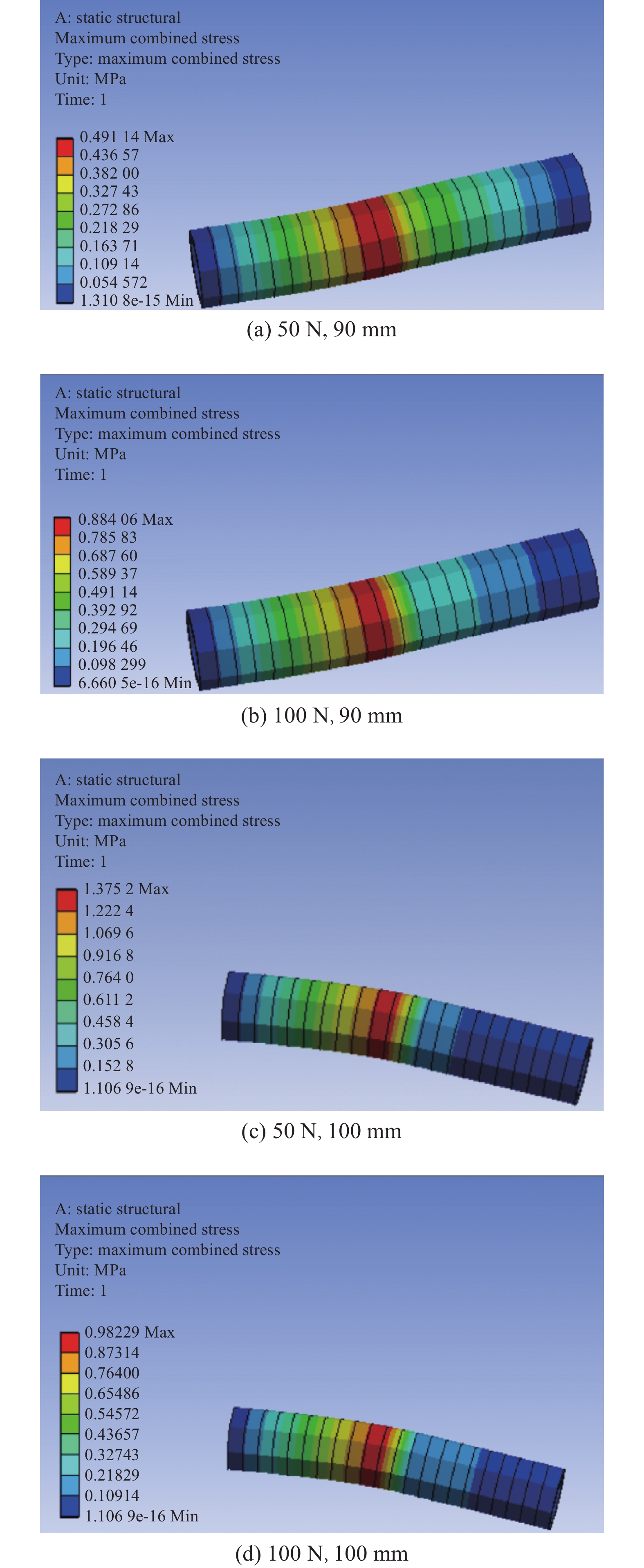

将螺钉结构简化为一个圆柱体,然后对常见的装配偏轴问题进行仿真分析,设螺钉长度为90.0 mm和100.0 mm两种,测偏程度由垂直于螺钉轴向施力程度决定,分别选择50 N和100 N作为对比参数,则仿真结果如图2所示。

由图2可以看出,施力大小的不同使应变具有明显的差异,施力越大,应变响应越大,在90.0 mm柱状体上,50 N和100 N的应力作用得到的应变最大值分别是0.491 MPa和0.884 MPa。在100.0 mm柱状体上,50 N和100 N的应力作用得到的应变量最大值分别是0.982 MPa和1.375 MPa。由此可见,结构长度对应变响应程度也会有影响的,当结构体越长,由于力臂作用增大,其应变响应程度也随之增大。并且根据仿真图中的应变分布可知,主要的受力位置集中在插入螺孔的边缘处。

-

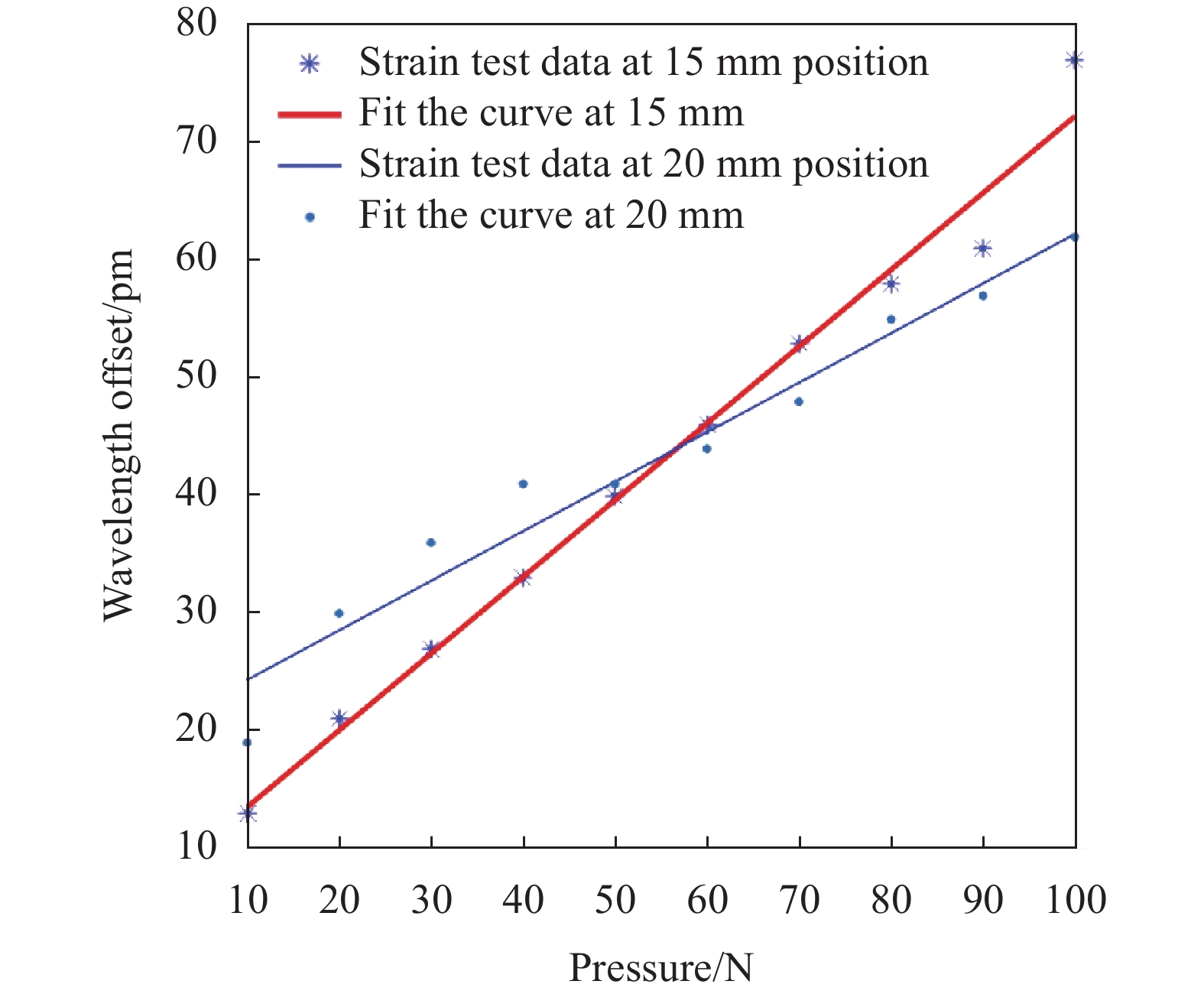

为了将测试用的所有FBG的应力响应系数都求解出来,所有采用悬臂梁实验进行标定。应变量化标定采用悬臂梁结构,悬臂梁长30.0 mm,一侧固定于支架,另一侧自由悬空,材料选用合金钢,弹性模量6.84×1010 Pa,泊松比为0.31,膨胀系数为21.2 μm/mK。将FBG粘贴于悬臂梁中间,测试实验分别距自由端15.0 mm和20.0 mm,施力范围[0,100 N],五次测量求一次均值,测试结果如图3所示。

由图3可以看出,无论测试位置是15.0 mm还是20.0 mm,其测试点都以线性变化递增,但拟合后的斜率不尽相同。15.0 mm的斜率明显比20.0 mm的更大。可见当测试FBG的位置距自由端越近,其应变响应能力越强。系统可以根据其应变响应参数完成对装配状态的检测。

-

为了模拟温度对应变的影响,在测试位置采用20 W电热灯加热,在FBG位置采用数字温度计进行测量,然后对比温度补偿前后的应变测试曲线,如图4所示。

由图4可以看出,在温度补偿前,应变测试结果随着温度的升高而产生波长偏移,相比之下,当通过温度偏移补偿后,应变测试值不再随温度变化而改变。可见,采用该系统中的温度补偿方式具有很好的温漂校正效果。

-

分别对15.0 mm和20.0 mm的螺钉进行施力测试,施加与装配轴向垂直的偏移应力,施力值设置为20~100 N,采用激光扫描设备测试相应位置的空间位置偏移量,用于对该系统FBG解算位置的对比,15.0 mm螺钉测试数据如表1所示,20.0 mm螺钉测试数据如表2所示。

Force

/NPosition deviation/mm Error FBGs Lidar 20 0.24 0.21 14.2% 40 0.49 0.44 11.4% 60 0.75 0.68 10.3% 80 0.97 0.89 8.98% 100 1.25 1.16 7.75% Table 1. Comparison of position deviation of 15.0 mm screws

Force

/NPosition deviation/mm Error FBGs Lidar 20 0.43 0.39 10.2% 40 0.78 0.72 8.3% 60 1.37 1.25 9.6% 80 1.85 1.69 9.5% 100 2.19 2.02 8.5% Table 2. Comparison of position deviation of 20.0 mm screws

由表1可知,当外部应力增大的时候,位置偏移量也随之增大,采用FBG的平均解算精度约为0.012 3 mm/N,而采用激光雷达测试得到的结果为0.0113 mm/N,可见,采用光纤传感获得的位置变化程度与激光雷达测试结果相近。

由表2可知,相比15.0 mm螺钉而言,20.0 mm螺钉在相同外部应力作用下产生的位置偏差更明显,采用FBG的平均解算精度约为0.0221 mm/N,而采用激光雷达测试得到的结果为0.0202 mm/N,说明结构体越长,得到的应变响应程度越明显。同时,相对误差精度可有所提高。对比两次测试还可以发现,偏移程度的增加虽然会改变偏移比率,但是整个过程始终保持线性变化,这样就保证了测试系统在整个拟合曲线上测试结果的稳定性。进一步验证了该方法的可行性。

-

文中提出了一种基于光纤传感的工业生产线智能装配系统,并针对螺钉装配进行了具体的仿真分析与实验讨论。对应变敏感程度、温度应变解耦算法以及位置校正参数计算等方面进行了实验验证。结果显示,系统具有很好的线性度,对温度干扰抑制能力强,位置偏移量误差小,适用于工业生产线自动装配过程,具有一定实用价值。

Intelligent assembly system of industrial production line based on optical fiber sensing

doi: 10.3788/IRLA20210695

- Received Date: 2021-12-25

- Rev Recd Date: 2022-02-18

- Available Online: 2022-11-02

- Publish Date: 2022-10-28

-

Key words:

- optical fiber network /

- industrial production line /

- intelligent assembly /

- decoupling algorithm

Abstract: The intelligent assembly technology of the industrial production line was a key means to improve the work efficiency of the production line and ensure the uniformity of the products. Increasingly complex industrial product structures have higher requirements for intelligent assembly control accuracy. Among them, feedback correction technology based on real-time online measurement has become a research hotspot. In order to realize the flexible measurement of the intelligent assembly process of industrial production lines, a feedback assembly control method based on optical fiber sensing was proposed. The system uses multiple FBG sensors to obtain the real-time strain of the assembly structure, and the temperature strain decoupling was completed by different packaged FBG sensors. Finally, the conversion of the degree of position deviation was completed by the way of neural network learning, and real-time correction of the assembly position was realized. Matlab was used to simulate the screw structure assembly process, and the stress distribution of screws with different lengths and force levels was simulated. The results show that the longer the screw length, the greater the strain under the same force. And the main strain of the screw is concentrated on the edge of the screw hole. In the experiment, the cantilever beam strain calibration experiment is used to obtain the fitting curves of different package states, the temperature calibration experiment is used to eliminate the temperature drift effect in the strain test data, and the position shift experiment is used to obtain the correction parameters. The results show that for a screw with a length of 15.0 mm, the average resolution of the system is about 0.012 3 mm/N, and for a screw with a length of 20.0 mm, the average resolution of the system is about 0.022 1 mm/N, and it has good linearity.

DownLoad:

DownLoad: