-

结构紧凑的高灵敏光纤传感器在锂电池内部温度原位测量等领域具有重要的应用价值[1-3]。目前,典型的光纤温度传感器主要包括光纤法布里-珀罗干涉仪[4]、光纤马赫-曾德尔干涉仪[5]、光纤迈克尔逊干涉仪[6]、光纤布拉格光栅[7]以及长周期光纤光栅[8]等。2017年,暨南大学光子技术研究院的Zhenshi Chen等通过将一段微结构光纤熔接在单模光纤的切割面上构成法布里-珀罗腔,制作了一个紧凑的原位温度传感器,其温度灵敏度为13.6 pm/℃[9]。2018年,东北大学信息科学与工程学院的Shuna Wang等人将一根单模光纤熔接在两根纤芯轴向偏移的单模光纤之间构成一个马赫-曾德尔干涉仪,并在其上涂上硅油封装在毛细钢管中,温度灵敏度和分辨率分别为8.962 nm/℃和0.0022 ℃[10]。2021年,清华大学清华-伯克利深圳学院的Yuanfang Zhao等基于平行双保偏光纤Sagnac结构,提出了一种新型的超灵敏迈克尔逊干涉仪温度传感器,通过优化保偏光纤的长度差实现温度灵敏度高达78.984 nm/℃、温度分辨率为±0.00063 ℃的温度测量[11]。2019年,西北大学光子学与光子技术研究所的张学强等采用铜、铝、有机玻璃、聚四氟乙烯等衬底材料对光纤布拉格光栅进行增敏封装,其温度灵敏度分别为30.42 pm/℃、34.76 pm/℃、94.29 pm/℃和128.76 pm/℃[12]。2016年,东北大学的Qi Wang等提出了一种基于聚二甲基硅氧烷涂层长周期光纤光栅的温度传感器,在20~80 ℃范围内实现了255.4 pm/℃的灵敏度以及0.078 ℃的分辨率[13]。

与法布里-珀罗干涉仪、光纤马赫-曾德尔干涉仪和光纤迈克尔逊干涉仪相比,光纤光栅具有紧凑的结构和实现准分布式测量的能力,但其温度灵敏度约为10 pm/℃[14]。为实现兼具结构紧凑和灵敏度高的温度传感器,文中报道了一种基于聚合物微球腔的温度传感器。微球腔采用连续全反射限制回音壁模式光场,具有较高的品质因子和较小的模式体积,即可从时域和空域上分别增强光与物质相互作用的等效长度和强度。因此,利用微球腔可在相同几何尺寸前提下实现灵敏度更高的原位测量。采用拉锥光纤耦合微球腔可激发品质因子达109量级[15]的回音壁模式,但两者之间的分离式耦合结构导致微球腔的耦合状态易受外界扰动的影响,为微球腔的实用化带来严重挑战。因此,研究微球腔的封装工艺是其实用化的关键。点封装[16]或者全包裹[17]采用光学胶粘接的方式将拉锥光纤和微球固定一体可在一定程度上提高微球腔的耦合稳定性,适用于带有光纤尾杆的微球腔[18],例如二氧化碳激光器或者电弧放电在光纤尾端制作的微球。对于温度传感而言,由于聚合物具有比二氧化硅更高的热光系数,利用聚合物微球腔可进一步提高微球腔的温度灵敏度。为利用化学合成的聚合物微球腔实现高灵敏度的温度传感,文中研究了一种将点封装和全包裹封装相结合的封装工艺,其中点封装用于初步固定聚合物微球腔和拉锥光纤光纤的轴向相对位置,以提高后续全包裹封装效率。采用拉锥光纤激发聚甲基丙烯酸甲酯(Polymethyl Methacrylate, PMMA)微球中的回音壁模式并利用低折射率光学胶对传感器进行封装处理,在20~30 ℃范围内实现了灵敏度为68 pm/℃的温度测量。

-

所提出的基于拉锥光纤耦合PMMA微球腔的温度传感器结构示意图如图1所示。根据目前能够达到的工艺参数和材料参数,首先利用有限时域差分法对该结构进行仿真分析。该结构由拉锥光纤耦合器和聚合物微球腔构成,拉锥光纤耦合器绿色部分是光纤的包层,黄色部分是光纤的纤芯。拉锥光纤耦合器导出消逝场,而后该消逝场进入聚合物微球腔激发回音壁模式。在仿真中,拉锥光纤的束腰直径和折射率分别设置为1.8 μm和1.4682,PMMA微球腔的直径和材料折射率分别设置为85 μm和1.4809。为了与微球腔的实际使用状态保持一致,将拉锥光纤与PMMA之间的间距设置为零,即两者保持接触状态。

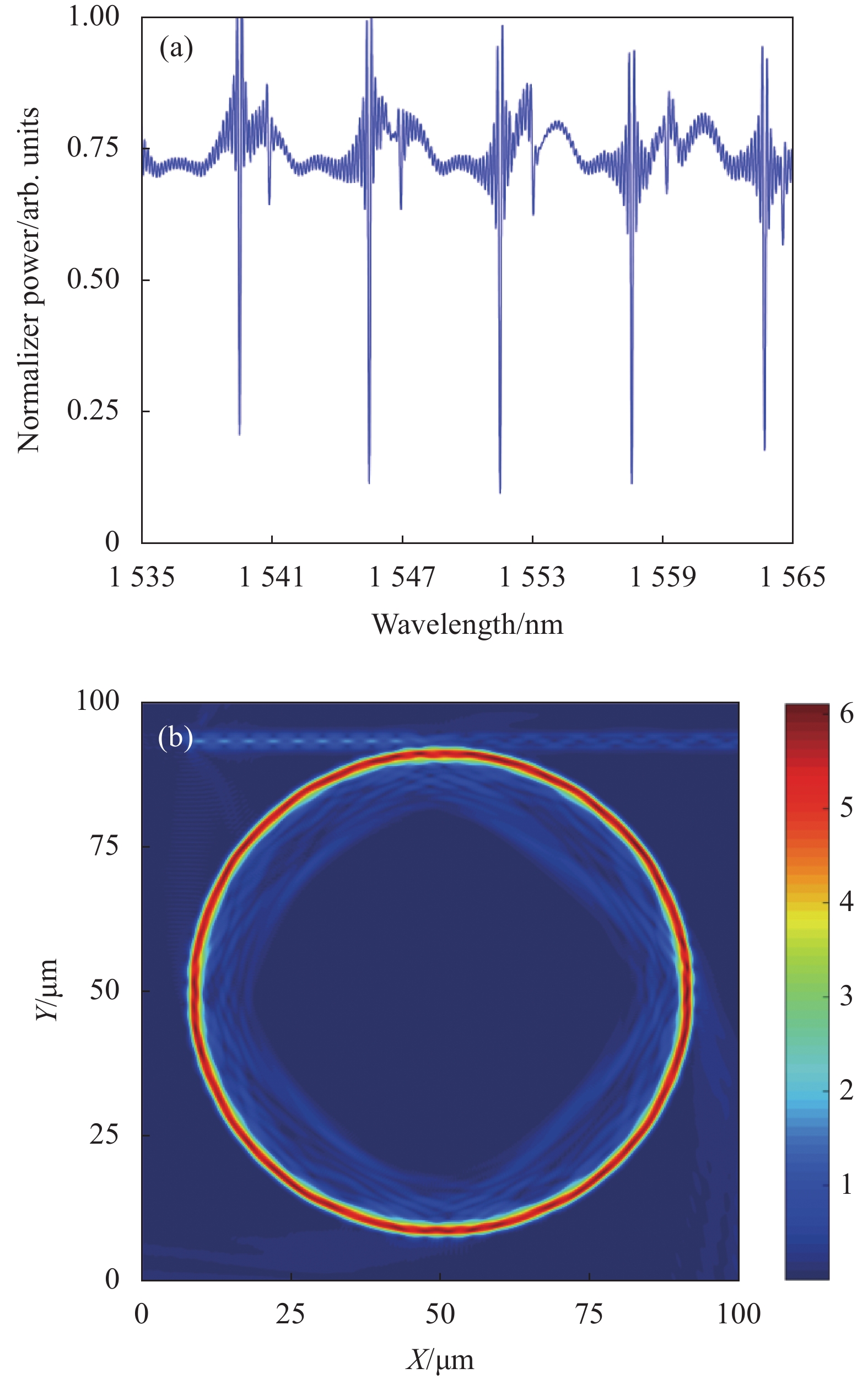

采用上述参数,在外界环境为空气的情况下仿真得到的谐振光谱如图2(a)所示。从图2(a)中可以看出,对于直径为85 μm的PMMA微球腔而言,其自由光谱范围(FSR)约为6.00 nm。与根据理论公式FSR=λ2/2πnr (其中,λ为光谱的中心波长,r为微球半径,n为微球腔中回音壁模式的有效折射率)计算得到的FSR (6.07 nm)吻合。图2(b)为谐振波长1551.47 nm处的回音壁模式光场分布,可以看出,采用束腰直径为1.8 μm的拉锥光纤可有效激发PMMA微球腔中的回音壁模式。

Figure 2. (a) Resonant spectrum of the microsphere cavity obtained by the finite-difference time-domain method; (b) Whispering gallery mode field distribution at the resonant wavelength 1551.47 nm

在利用回音壁模式光学微腔进行温度传感时,拉锥光纤的消逝场将根据相位匹配条件耦合到PMMA微球腔中激发回音壁模式。微球腔的谐振波长与其半径和有效折射率之间的关系可以近似表示为:

式中:m为回音壁模式的角模式数;λr为微球腔的谐振波长。

当微球腔所处的环境温度发生变化时,微球腔自身的热光效应和热膨胀效应将导致回音壁模式的有效折射率和微腔尺寸发生改变,从而导致微球腔的谐振波长发生漂移。微球腔的谐振波长漂移量(dλ)与温度变化量(dT)之间的关系可表示为:

式中:dλ/dT为微球腔的温度灵敏度;λr为微球腔的谐振波长;neff为回音壁模式的有效折射率;dneff/dT=−1.2×10−4/℃为PMMA微球腔的热光系数;dr/dT= 7×10−5/℃为PMMA微球腔的热膨胀系数。从公式(2)可以看出,材料的热光系数和热膨胀系数越大,微腔性质随温度的变化量越大,器件的温度灵敏度越高。实验中使用的PMMA材料具有正的热膨胀系数和负的热光系数。根据公式(2),当温度升高时,PMMA微球腔热光效应导致谐振波长发生蓝移,而热膨胀效应导致谐振波长发生红移。由于PMMA微球腔的热膨胀系数比小于其热光系数,其谐振波长随外界环境温度升高发生蓝移。

-

所报道的聚合物微球腔温度传感器由拉锥光纤耦合器和PMMA微球腔组成,其中拉锥光纤采用热拉伸法制作,所使用的光纤为普通单模光纤(Corning SMF-28e)。为拉制束腰直径不超过2 μm的锥形光纤耦合器,实验中采用氢气火焰加热光纤并同时利用电控位移平台沿轴向拉伸光纤。通过优化氢气流量、火焰高度以及电控位移台速度等参数可制作束腰直径为1~2 μm的拉锥光纤耦合器。

为实现稳定的耦合状态且保护拉锥光纤耦合器和PMMA微球腔免受外界污染物的影响,采用通过结合点封装和全包裹封装的方法将拉锥光纤耦合器和PMMA微球腔均封装在低折射率胶(PC 340HA)中。PMMA微球腔与拉锥光纤耦合器的封装工艺包括以下四个步骤,如图3所示:(a)将由低折射率胶制成的垫片平铺在热电制冷片(TEC)上;(b)将通过加热熔融法制成束腰直径约为1.8 μm的拉锥光纤固定在TEC上,拉锥光纤的两端涂胶后用紫外灯进行固化,为了不影响下一步中拉锥光纤与PMMA微球腔的耦合效果,该步骤中拉锥光纤保持绷直状态;(c)选择尺寸合适的PMMA微球腔并利用三维位移台将PMMA微球腔转移至拉锥光纤束腰处,通过点涂低折射率胶的方式将PMMA微球腔固化至拉锥光纤的束腰处;(d)利用紫外灯将耦合处的低折射率胶进行固化,使整个耦合系统保持相对稳定状态。由于PMMA微球腔在胶过多的情况下会随着胶的流动而改变位置,因此,在确保PMMA微球腔与拉锥光纤不会随着胶的流动性影响耦合效果后,可将更大剂量的胶涂覆在整个平面并用紫外灯进行固化,从而将整个器件包裹在低折射率胶中。

Figure 3. Schematic diagram of the tapered fiber coupled PMMA microsphere cavity packaging process: (a) Placing a low-index rubber gasket on the TEC; (b) Fixing the tapered optical fiber on the gasket; (c) Transferring a PMMA microsphere cavity to the waist of the tapered fiber and then packaging them together by spot curing; (d) Coating and curing the whole device with the low refractive index adhesive

-

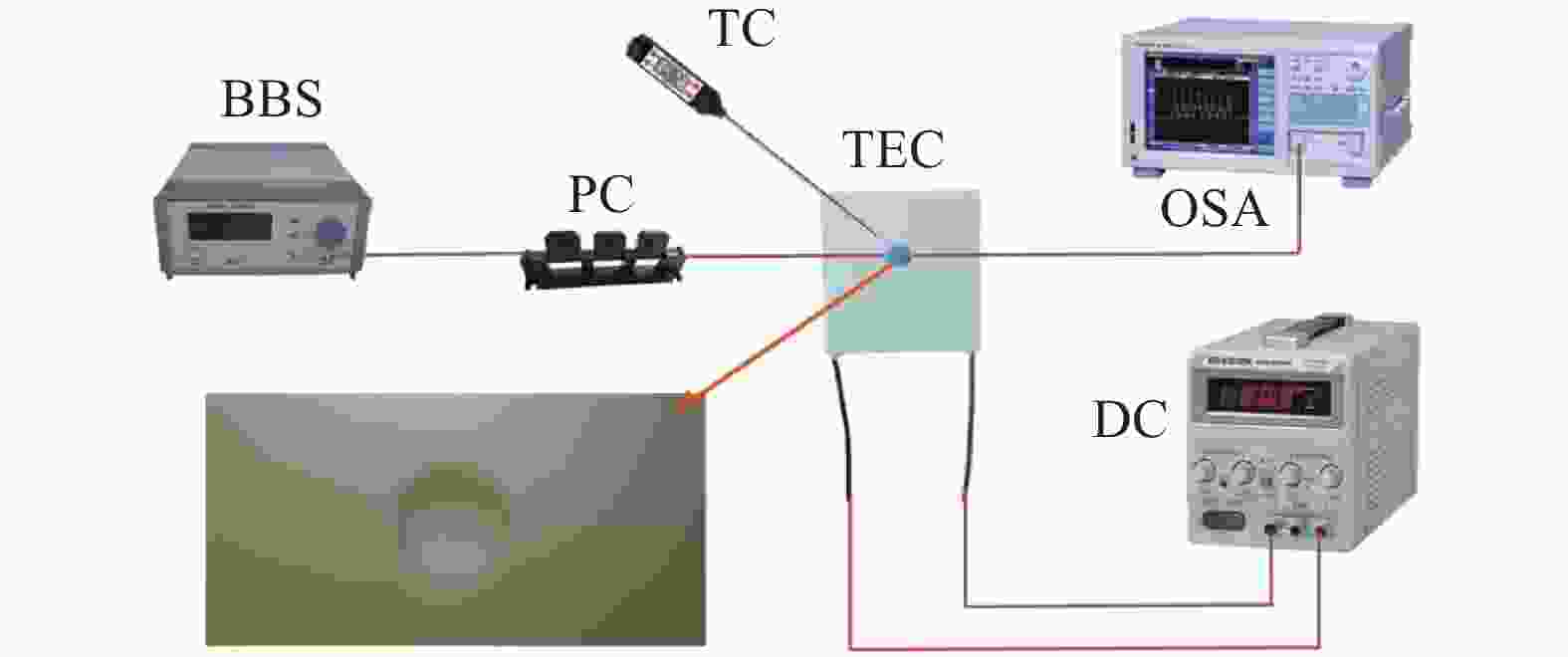

图4为利用上述封装器件测量温度的实验装置示意图,其中波长范围为1535~1565 nm 的宽带光源(BBS)用于激发回音壁微腔,光纤偏振控制器(PC)用于调节PMMA微球腔输入光的偏振态,直流(DC)供电的TEC用于模拟外界环境温度变化,光谱分析仪(OSA,AQ6370D, YOKOGAWA)用于记录PMMA微球腔在不同温度环境下的谐振光谱。实验中,将PMMA微球腔封装至TEC的制冷面,通过改变TEC中的电流模拟在20~30 ℃范围内变化的温度环境。为了标定PMMA微球腔的温度,将热电偶(TC)贴附于PMMA微球腔附近。

Figure 4. Schematic diagram of experimental setup for measuring the temperature response of the PMMA microsphere cavity

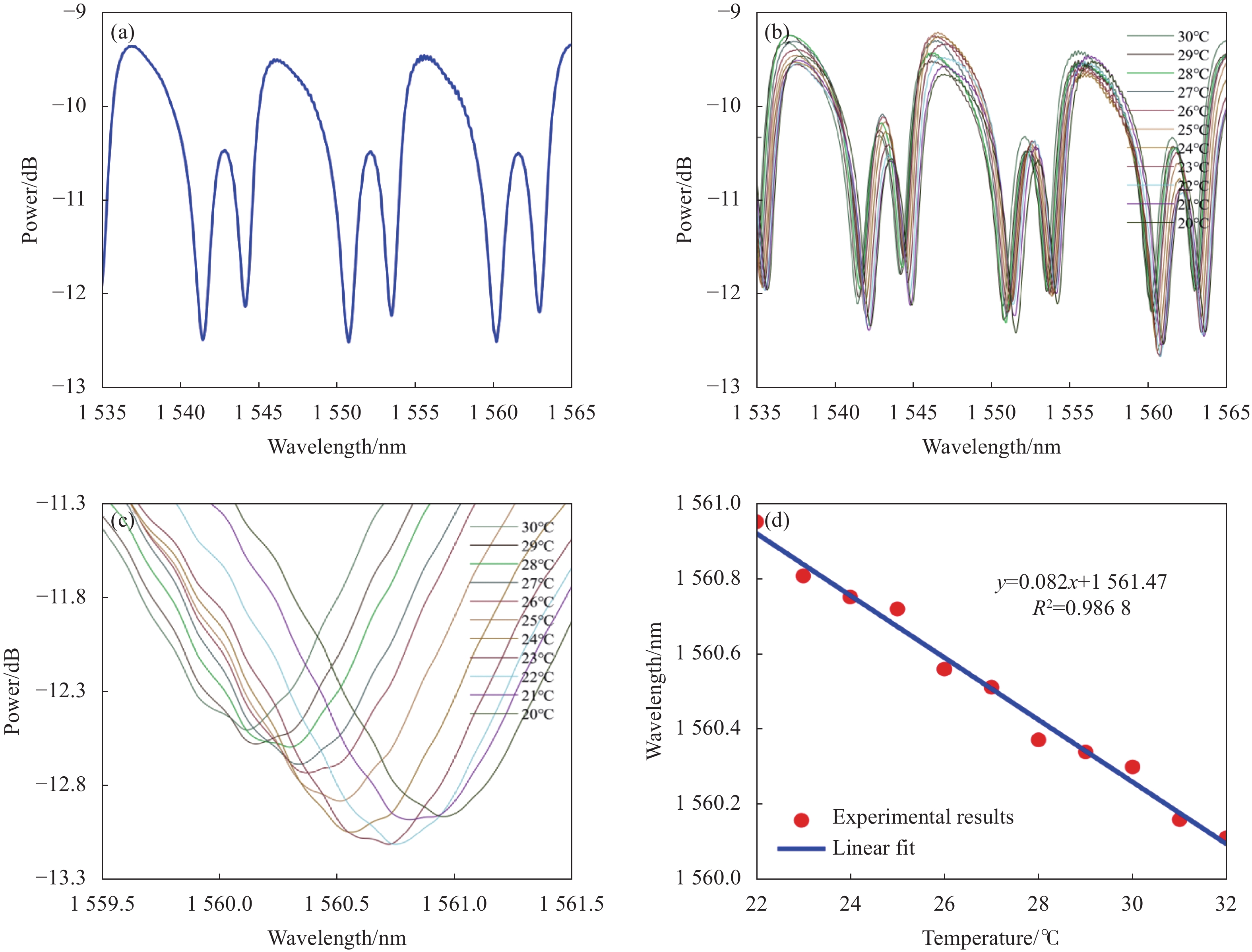

当直流电压源的输出电流以0.03 A的步幅从0 A缓慢调节至0.6 A时,热电偶监测结果表明,TEC上表面的温度可从30 ℃降低至20 ℃。在此温度变化过程中,束腰直径为1.8 μm拉锥光纤耦合的直径为85 μm的PMMA微球腔的谐振光谱如图5(a)所示。拉锥光纤耦合器和PMMA微球腔保持接触可实现稳定的耦合状态,但也易同时激发多种回音壁模式,出现非对称的类Fano线型。从图5(a)中可以看出,PMMA微球腔中回音壁模式的自由光谱为6.22 nm,与理论结果(FSR=6.25 nm)之差为0.03 nm。

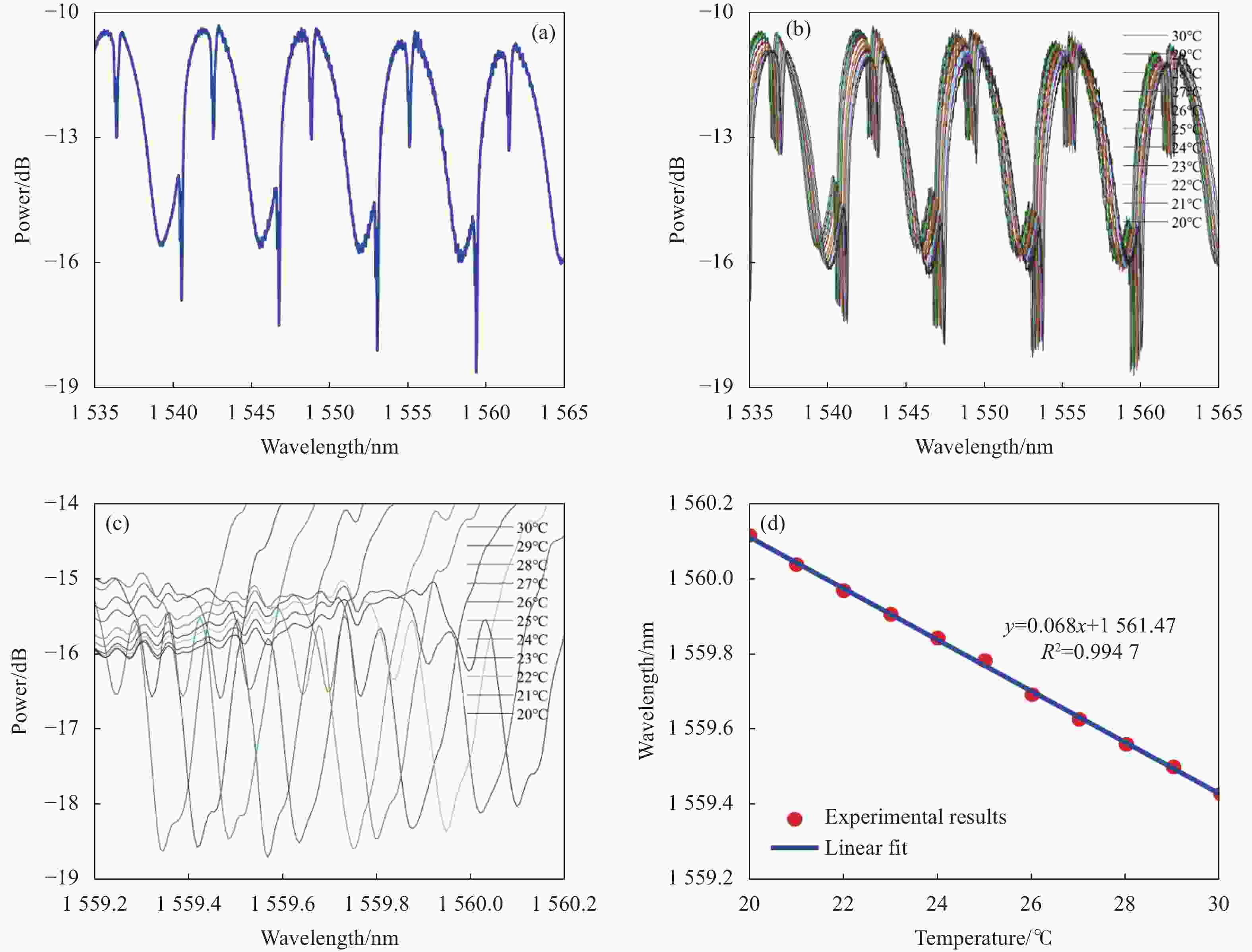

Figure 5. (a) Resonant spectrum of the PMMA microsphere with a diameter of 85 μm in the range from 1535 nm to 1565 nm; (b) Resonant spectra of the PMMA microsphere under different temperatures; (c) The details of the spectra around 1559.7 nm in (b); (d) Wavelength shift of the PMMA microsphere with respect to temperature

图5(b)为在第一次降温过程中PMMA微球腔谐振光谱,从左到右分别为温度以1 ℃的步幅从30 ℃降温到20 ℃的光谱。图5(c)为图5(b)中谐振波长1559.7 nm附近的放大光谱,当环境温度变化量为10 ℃时,PMMA微球腔谐振波长的漂移量为0.7981 nm。实验中,通过三次降温-升温过程测量该器件的温度响应特性。实验结果表明,PMMA微球腔谐振光谱的重复性误差为0.026,表明该微球腔在升降温过程中具有良好的一致性。通过将1559.7 nm附近PMMA微球腔谐振波长的六次测量结果取平均并经线性拟合可得到当外界环境温度在20~30 ℃范围内变化时,该器件的温度灵敏度为68.14 pm/℃,如图5(d)所示。

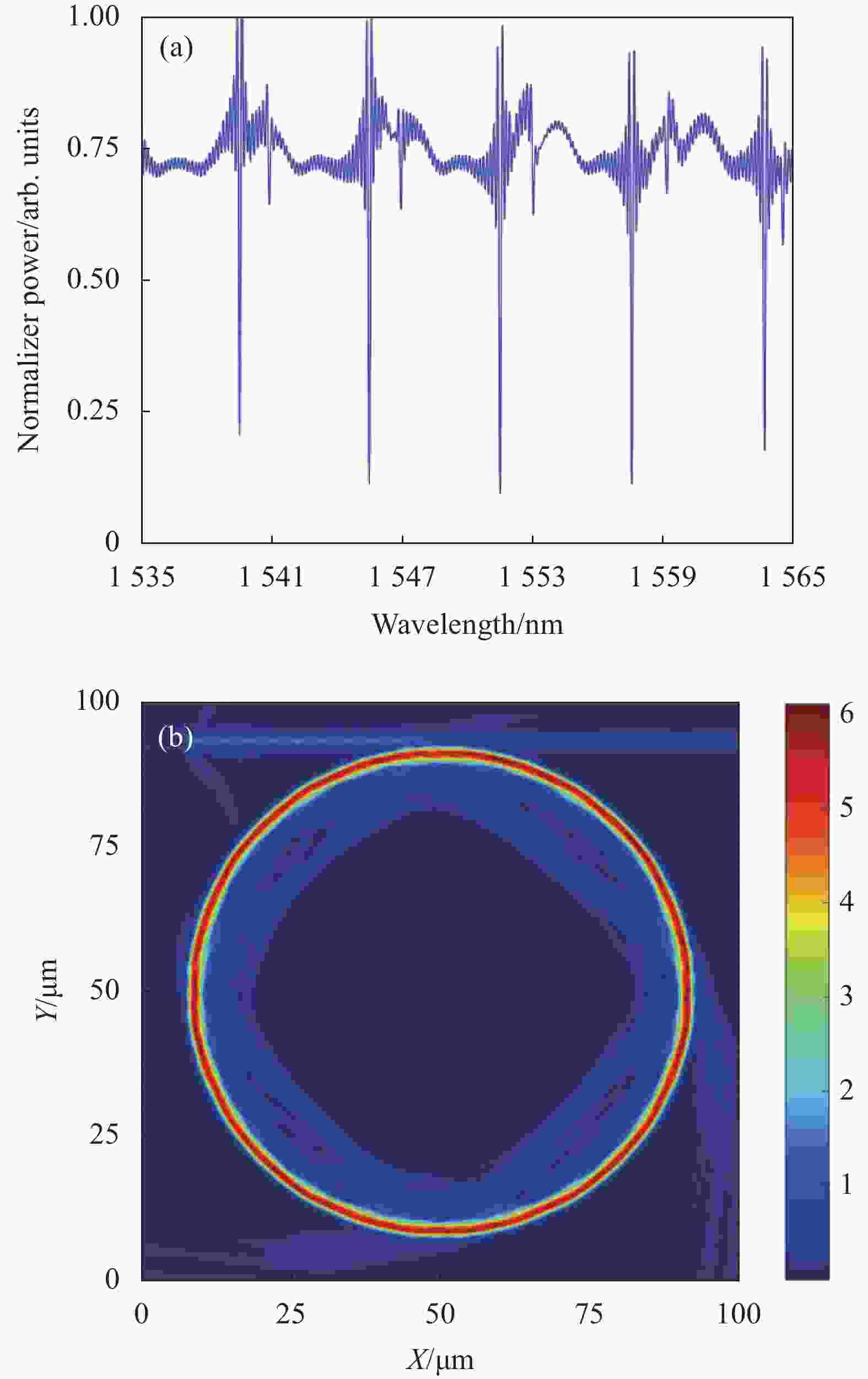

采用上述封装工艺和测试方法,对直径为102 μm的PMMA微球腔进行了温度响应测试,其结果如图6所示。当外界环境温度在20~30 ℃范围内变化时,该微球腔的谐振波长在1560.5 nm附近的温度灵敏度为82 pm/℃,略高于图5(d)所示的结果,其主要原因在于全包裹封装时无法保证两个器件表面低折射率光学胶的分布状态一致。

Figure 6. (a) Resonant spectrum of the PMMA microsphere with a diameter of 102 μm in the range from 1535 nm to 1565 nm; (b) Resonant spectra of the PMMA microsphere under different temperatures; (c) The details of the spectra around 1560.5 nm in (b); (d) Wavelength shift of the PMMA microsphere with respect to temperature

与传统的光纤温度传感器相比,文中报道的聚合物微腔温度传感器的测量范围受限于微腔本身的材料,但在相同轴向尺寸的前提下呈现更高的灵敏度。除灵敏度外,分辨率是温度测量的另一关键参数。对于通过波长漂移解调温度变化的传感器而言,温度传感器的探测极限与其灵敏度、光谱仪波长分辨率以及传感器本身的带宽(微腔的品质因子)等参数紧密相关[19]。在文中,聚合物微腔的品质因子约为1.04×104,高于传统的光纤布拉格光栅或者干涉仪,因此可实现更高的温度分辨率。

-

文中报道了一种基于拉锥光纤耦合的聚合物微球腔的高灵敏温度传感器及其封装方法。利用有限时域差分法仿真分析了在相位匹配条件下拉锥光纤消逝场激发PMMA微球腔中的回音壁模式。理论分析了回音壁模式微球腔的热光效应和热膨胀效应对共振波长漂移方向和漂移量的影响,由于PMMA微球腔的负热光系数大于其热膨胀系数,其谐振光谱随外界温度降低发生红移。详细介绍了结合点封装和全包裹封装将拉锥光纤和聚合物微球封装一体的工艺流程。实验结果表明,拉锥光纤与聚合物微球之间通过消逝场耦合的方式能够在1550 nm附近激发品质因子为104量级的回音壁模式。当外界环境温度在20~30 ℃范围内变化时,PMMA微球腔的温度灵敏度可达68.14 pm/℃。与相同几何尺寸的传统光纤温度传感器相比,聚合物微球腔温度传感器具有更高的灵敏度,因此在受限空间的局域温度原位测量中具有重要的潜在应用价值。

Highly sensitive temperature sensor based on polymer spherical microcavity (invited)

doi: 10.3788/IRLA20220535

- Received Date: 2022-08-01

- Rev Recd Date: 2022-09-08

- Available Online: 2022-11-02

- Publish Date: 2022-10-28

-

Key words:

- temperature sensor /

- microcavity /

- whispering gallery mode /

- polymer

Abstract: A temperature sensor based on polymer microsphere cavity is proposed, which measures the change of external temperature through the resonant wavelength shift and demonstrates the characteristics of high compactness and sensitivity. The finite-difference time-domain method is firstly employed to simulate the structure of tapered fiber coupled polymethyl methacrylate (PMMA) microspheres to verify its feasibility of whispering gallery mode excitation. Experimental results show that whispering gallery mode with a quality-factor on the order of 104 can be excited by evanescently coupling a polymer microsphere with a diameter of tens of micrometers through a tapered fiber with a diameter of 1.8 μm. Packaging the device by combining spot and complete coating can keep a stable coupling state between the tapered fiber and the microsphere and protect them from external contaminant. Red shift happens in the resonant spectrum of the microsphere cavity as the external temperature decreases since its negative thermo-optic coefficient is larger than the thermal expansion coefficient. When the external temperature varies in the range of 20-30 ℃, the polymer microsphere demonstrates a sensitivity of 68 pm/℃. In comparison with the conventional optical fiber sensors, lower detection limit can be achieved by the proposed temperature sensor with a higher quality-factor, which can be potentially used in the in-situ temperature precise measurement in a limited space.

DownLoad:

DownLoad: