-

中红外光纤光源包含了分子的“指纹区”,具有结构紧凑、输出灵活以及散热性能好的优势,在生物医学、光电对抗、高光谱成像等领域具有重要的应用价值[1]。其中,工作在荧光和激光之间的超荧光光源(superfluorescent fiber sources, SFS)不仅具有空间相干性好、发射光谱宽、亮度高等特性,与激光相比,还有无模式竞争、无弛豫振荡、高时域稳定性的特点[2],已被应用于气体探测[3]、光学相干层析成像[4]、以及光纤传感[5]等领域。

目前有关超荧光的报道大多集中在1~2 µm的近红外波段,在中红外波段却少有报道。2014年,澳大利亚悉尼大学的Iwanus等人利用1150 nm和1950 nm的激光双向泵浦一段13 m长的掺Ho3+氟化物光纤,获得光谱中心在2.9 µm、半高带宽为75 nm、平均功率为40 mW的中红外超荧光[6]。同年,电子科技大学的罗鸿禹团队通过优化光纤端面角度和泵浦方式,将中红外超荧光功率提升至220 mW,光谱的半高带宽为26 nm[7]。2021年,日本秋田县立大学的Goya等人利用976 nm的激光泵浦一段Er3+/Dy3+共掺双包层氟化物光纤,获得了范围从2515~3735 nm的超宽中红外超荧光,尽管其输出功率只有2.5 mW,但已被成功用于甲烷气体探测[8]。同年,湖南大学的赵楚军团队利用976 nm激光泵浦一段长3.8 m,掺杂浓度7 mol.%的掺Er3+氟化物光纤,获得224 mW、半高带宽14 nm的超荧光种子,再级联一段2 m长的掺Er3+氟化物光纤,实现中红外超荧光的功率放大,获得平均功率1.85 W的中红外超荧光输出[9]。2022年,电子科技大学的罗鸿禹团队利用非保偏掺Er3+氟化物光纤输出的中红外超荧光做种子,利用全保偏掺Er3+氟化物光纤对其进行放大,实现线偏振中红外超荧光输出,光谱的20 dB带宽为95 nm,输出功率达2.3 W,这也是目前中红外超荧光的最高功率报道[10]。然而,以上所有工作都是基于空间结构泵浦实现的,这主要是中红外侧面泵浦合束器的缺乏所致。空间泵浦的方案需要对泵浦光先准直再聚焦到增益光纤端面的包层中,实现泵浦光的耦合,通过双色镜和长波滤波片实现中红外超荧光的过滤。该方案结构复杂,系统稳定性差,且由于氟化物光纤易潮解,端面泵浦使氟化物光纤端面易受损,注入的泵浦功率因此受限。2020年,加拿大麦吉尔大学的Long等人将泵浦光的石英尾纤与掺Dy3+氟化物光纤直接熔接实现全光纤中红外放大的自发辐射光(amplified spontaneous emission, ASE)输出[11],但是该法只能通过前向输出,输出光中红外占比很低,实验中仅测得光谱,并未测出中红外的实际功率。事实上,后向产生的超荧光功率要远高于前向输出。因此,研制中红外侧面泵浦合束器不仅可以实现中红外超荧光的全光纤化、克服空间泵浦带来的问题,也可以通过后向输出实现高功率的中红外超荧光输出。但是目前与成熟的石英光纤泵浦信号合束器相比[12],有关中红外侧面泵浦合束器的研究非常少。

2018年,日本三菱钻石工业株式会社的SCHÄFER等人通过机械研磨、侧面熔接的方法,在包层直径240 µm的掺Er3+氟化物光纤上制备了中红外侧面泵浦合束器[13]。该方案需要对氟化物光纤进行角度抛光、熔接等操作,对机械加工精度要求很高,制作难度大。2020年,加拿大拉瓦尔大学根据拉锥光纤侧面耦合的原理,在包层尺寸为240× 260 µm的掺杂氟化物光纤和包层直径为250 μm的非掺杂氟化物光纤上分别实现了通过率达88.1%和92.8%、最高泵浦注入功率44 W和91 W的中红外侧面泵浦合束器的制作封装[14]。该方法无须对氟化物信号光纤进行后处理即可实现泵浦光的高效、高功率耦合和长时间运行,为实现中红外光纤光源的全光纤化提供了有力的解决方案。

文中首次在125 μm包层直径的无源氟化物双包层光纤上实现中红外侧面泵浦合束器的研制,合束器泵浦光耦合效率达82.3%,可承受的最大泵浦功率达87.5 W。此外,文中在掺Er3+氟化物双包层光纤上制成中红外侧面泵浦合束器,获得全光纤中红外超荧光光源,前后向输出的中红外超荧光最高功率和为91.09 mW。在中红外超荧光输出功率达33.03 mW时,获得了108 nm的20 dB最大带宽。这是国内外首次利用中红外侧面泵浦合束器实现全光纤中红外超荧光光源产生的报道。

-

该节以无源双包层氟化物光纤作为合束器的信号光纤,在无源氟化物双包层光纤(DC-ZBLAN)上制得侧面泵浦合束器,重点研究合束器的制作工艺流程,研究泵浦光纤拉锥参数对合束器耦合效率的影响,研究合束器高功率泵浦下的输出功率、温度特性。

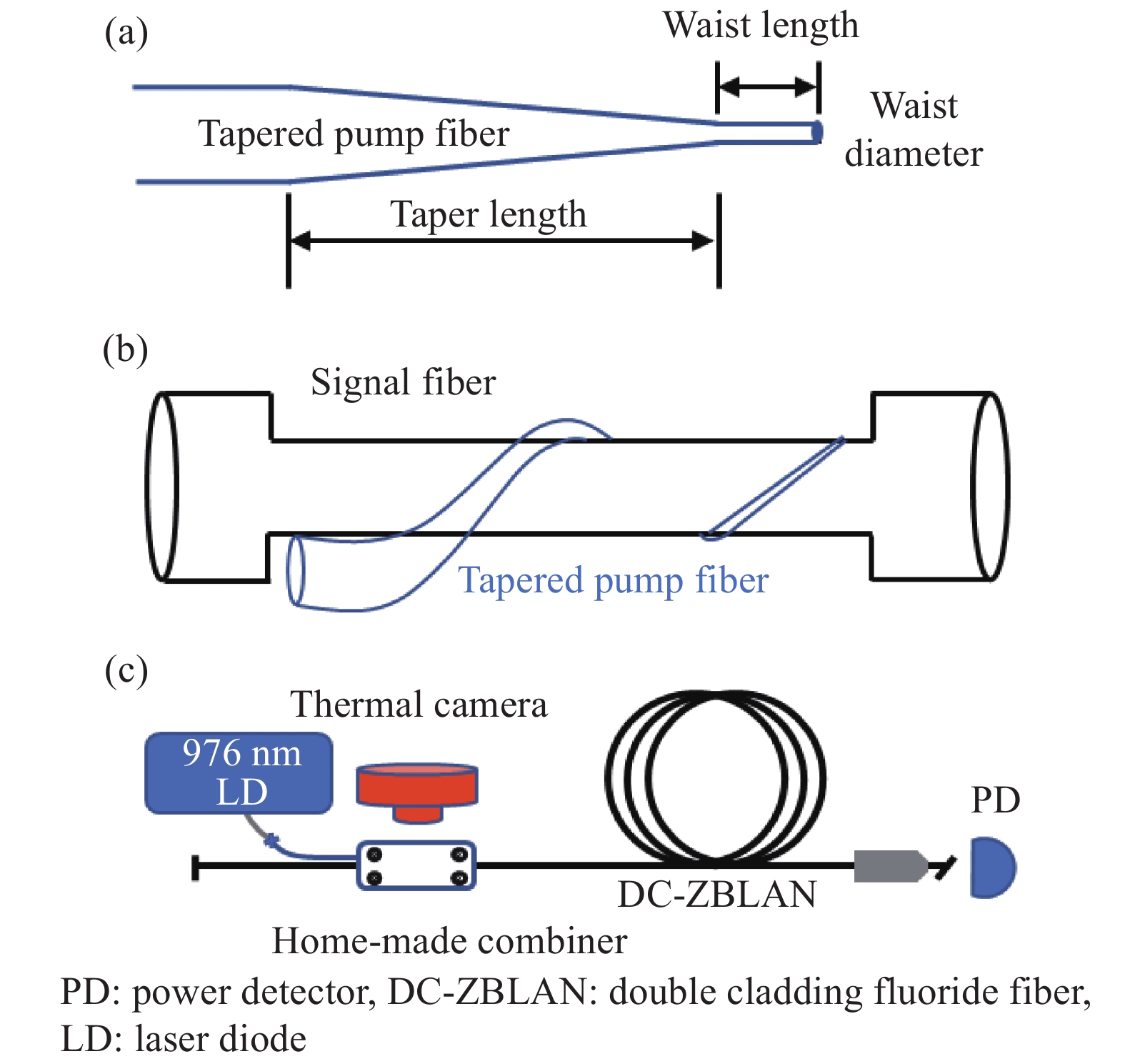

实验中首先利用拉锥机将一段包层直径为125 µm的无芯石英光纤(NA=0.46)进行拉锥,拉锥光纤示意图如图1(a)所示,拉锥后的无芯光纤包含三个参量,锥区长度(taper length)、腰区长度(waist length)、腰区直径(waist diameter),在拉锥后对无芯光纤的另一边锥区进行切割,不再保留。拉锥光纤为侧面泵浦合束器的泵浦光纤,合束器的信号光纤为无源双包层氟化物光纤,其纤芯及内包层直径分别为12/125 µm,数值孔径分别为0.23/0.4,长度约2 m。信号光纤后向输出端切平角,前向输出端切12°角。实验中先将信号光纤涂覆层剥除约10 cm,然后将拉锥光纤最细的腰区及锥区尾端部分贴紧在泵浦光纤上,再轻轻拉直拉锥光纤,使其剩余锥区能够直直地贴合在泵浦光纤上,由于腰区及锥区尾端部分很细,贴合到信号光纤上呈现出的是一个自然卷曲的状态。整个过程用酒精固定以提高两光纤间的粘附力,示意图如图1(b)所示。当酒精挥发后,两光纤很容易互相脱落。实验中自制了合束器夹具,用来承载贴合了泵浦纤的信号纤,然后浸入胶水固化,进行封装。与此同时,用一热释电功率探测器(power detector, PD)实时监测合束器前向输出功率,确保胶水在浸入过程中,两光纤接触良好、不会脱落。为进一步测试合束器耦合效率及发热情况,拉锥光纤泵浦端与实测最大输出功率87.5 W的976 nm半导体激光器多模尾纤(105/125, 0.22)相熔接,合束器前向输出功率由热释电功率探测器实时测得,合束器光纤温度由热像仪实时监测,测试过程如图1(c)所示。在合束器温度监测过程中,并未加主动冷却装置。

Figure 1. (a) Schematic diagram of tapered pump fiber parameters; (b) Schematic diagram of the pump-signal coupling process; (c) Diagram of combiner test device

在未浸胶水的状态下,测得低功率(1 W)泵浦下,不同拉锥参数的光纤作为泵浦纤时合束器的泵浦光耦合效率,如表1所示。合束器耦合效率由功率计测得的前向输出稳定功率除以泵浦功率得到。由于无源氟化物光纤损耗低,在计算耦合效率时,忽略了信号光纤传输损耗的影响。

Taper length/cm Waist length/cm Waist diameter/μm Coupling efficiency 1.5 1.5 ~15 55.9% 3 1.5 ~15 69.5% 4 1.5 ~15 75.3% 5 1.5 ~15 80.2% 5 2.5 ~15 75.6% 5 1.5 ~30 70.8% 6 1.5 ~15 78.1% Table 1. Test results of combiner’s coupling efficiencies under different pump fiber tapering para-meters

从表1可以看出,在锥区长度、腰区长度和腰区直径为1.5/3 cm、1.5 cm和15 µm时,合束器耦合效率较低,为55.9%和69.5%。在锥区长度、腰区长度和腰区直径为5 cm、1.5 cm和30 µm时,合束器耦合效率较低,为70.8%。这是因为锥区长度过短、腰区直径过大,均会导致部分泵浦光没能泄露出去,残留在拉锥光纤内。因此,为实现较高耦合效率的合束器,应保证锥区长度大于4 cm,腰区直径小于20 µm。最后,根据7组实验结果中测得的最高耦合效率,将封装合束器的泵浦光纤参数定为锥区长度5 cm、腰区长度1.5 cm、腰区直径15 µm。

封装后的合束器输出功率随泵浦功率的演化如图2(a)所示,在0~87.5 W的泵浦功率范围内,合束器输出功率基本随泵浦功率线性增加,耦合效率约为82.3%。在最大泵浦功率下,合束器输出功率达到71.3 W。图2(b)为合束器夹具(未盖夹具盖)最高温度点随泵浦功率的演变图,合束器封装实物图及温度热像图如图2(b)内插图所示。由图2(b)可以看出,当泵浦功率大于10 W后,合束器温度随泵浦功率线性增加,在最大泵浦功率87.5 W下为105 ℃,虽未达到氟化物光纤软化温度(~250 ℃),但已接近固化胶水的工作温度上限(~130 ℃)。未来合束器功率的进一步提升主要受固化胶水工作温度的限制。合束器夹具发热最严重的地方主要在拉锥光纤耦合区域尾端,这是因为大部分泵浦光功率在腰区部分耦合入信号光纤,同时未进入信号光纤的残余泵浦光也主要在此位置泄露,这加剧了合束器夹具的发热。未来可以通过提高合束器泵浦光耦合效率并对其进行主动冷却处理,以有效降低其温升。

Figure 2. (a) Evolution diagram of combiner output power with pump power increasing; (b) Evolution diagram of combiner holder’s temperature with pump power increasing

与以往报道的250 µm包层直径的信号光纤相比,实验所用信号光纤包层直径为125 µm,其涂覆层的剥除、制作工艺难度相对更大,且耦合效率小于250 µm包层直径的信号光纤侧面泵浦合束器[14]。

-

该节依据第1节确定的拉锥参数、制作方法,直接在掺杂氟化物双包层光纤上研制、封装了侧面泵浦合束器,并基于该合束器搭建了全光纤中红外超荧光光源。

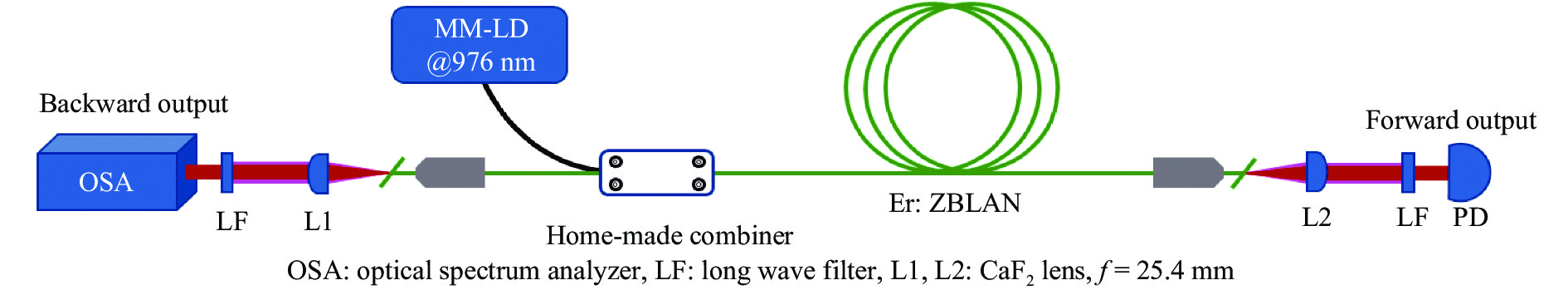

实验结构如图3所示,所用增益光纤泵浦源为一商用976 nm半导体激光器,其最大输出功率为27 W,尾纤为纤芯105 µm、数值孔径0.22的多模光纤。信号光纤为一段长度为4.5 m的掺Er3+氟化物双包层光纤,其掺杂浓度是10000 ppm (1 mol.%),纤芯及内包层尺寸分别为16.5/240 × 260 µm,所对应的数值孔径分别为0.12/0.45。合束器泵浦光纤的拉锥参数与第1节相同,信号光纤的两端均切12°角以降低激光自激振荡阈值,提高中红外超荧光的输出功率。在实验中,对后向输出功率和前向输出功率进行了测量。测量时两端输出的光先通过氟化钙透镜(L1和L2,焦距均为25.4 mm)以实现准直,再通过一个2.4 µm的长波滤波片(long wave filter, LF)以滤除976 nm的残余泵浦光和1550 nm附近的超荧光,获得纯净的中红外超荧光。输出功率由热释电功率探测器(power detector,PD)测得,输出光谱由测量范围在1500~3400 nm的光谱仪(optical spectrum analyzer, OSA)测得,光谱仪扫描分辨率为0.5 nm。

后向输出的中红外超荧光光谱演化图如图4(a)和(b)所示。Er3+能级结构图如图5所示。从图4(a)可以看出,当泵浦功率升至0.39 W,2714 nm附近的光谱峰最先被激发。随着泵浦功率的进一步增加,整个增益带宽内的光谱强度均得到增强,但是当泵浦光增加到1.4 W后,大部分泵浦能量开始向2780 nm左右的长波区转移,位于2780 nm附近的长波光谱增长幅度明显变大,而短波增长幅度变缓。这是因为随着泵浦功率增加时,Er3+激发态能级 4I11/2上累积的粒子数不断增加,亚稳态能级4I13/2的终止斯托克斯能级提升导致激发波长变长。当泵浦功率升至1.8 W时,2714 nm的短波峰升至最高值。

Figure 4. (a) Evolution of mid-infrared superfluorescence spectra at the pumping power of 0.39-1.8 W; (b) Evolution of mid-infrared superfluorescence spectra at pump power of 1.8-5.6 W

当泵浦功率超过1.8 W时,2714 nm处的短波分量开始减小,2785 nm附近的长波分量幅值继续增大,这种光谱的红移现象是由于泵浦光的增加,亚稳态能级4I13/2上累积的粒子数增多,会吸收短波分量2 714 nm的光子,粒子会重新跃迁至激发态能级4I11/2,激发态能级4I11/2上的粒子发射长波分量2 785 nm的光子,跃迁至亚稳态4I13/2较高斯托克斯能级。当泵浦功率为2.6 W时,在2705~2813 nm范围内获得了光谱20 dB、最大带宽为108 nm的中红外超荧光。随着泵浦功率的继续提升,短波部分的重吸收使得光谱20 dB带宽开始窄化,当泵浦功率提升至5.2 W时,超荧光光谱的短波边和长波边分别达至2702 nm和2830 nm,此时光谱的20 dB带宽窄化为70 nm。当入射泵浦功率超过5.4 W时,2785 nm的光谱峰开始变得尖锐,这是激光的自激振荡,主要由光纤中增益的累积以及端面反馈所致。当泵浦功率进一步增大到5.6 W,输出光谱中的自激振荡变得更加明显,最终呈现出一个明显的单色窄带激光光谱。注意到在整个中红外超荧光光谱分布中,光谱毛刺较多,并不平滑,这是因为2.7~2.8 µm正好位于水分子的吸收峰,在测量光谱时由空气中的水吸收造成的。

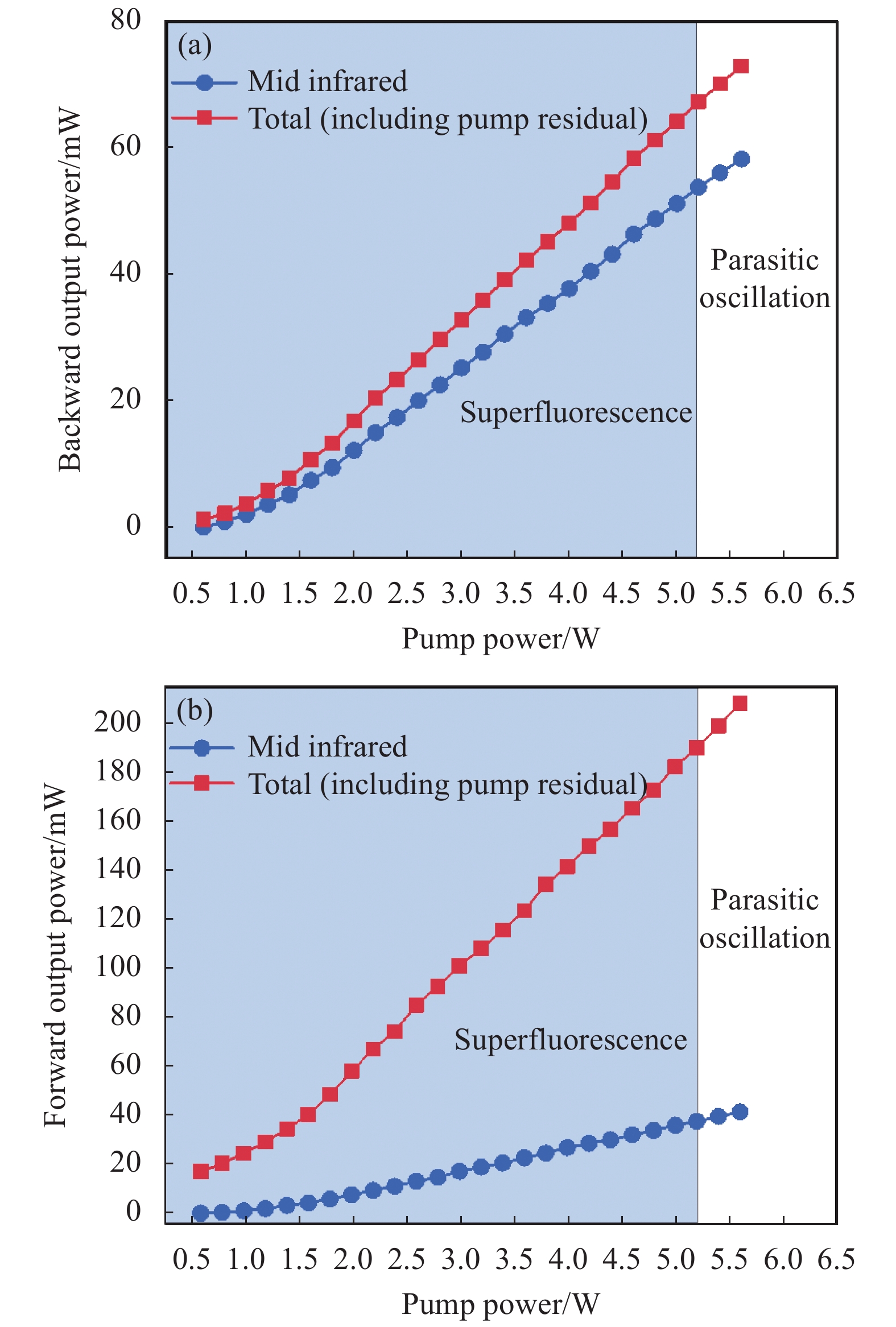

后向和前向输出的总功率(包含976 nm残余泵浦光及1550 nm光)及中红外超荧光功率分别如图6(a)和(b)所示。从图6(a)和(b)中可以看出,在泵浦功率大于1.25 W时,后向和前向输出的总功率及中红外超荧光功率随泵浦功率线性增加。在泵浦功率达到5.2 W时,后向泵浦和前向泵浦端输出的中红外超荧光最大功率分别为53.67 mW和37.42 mW,前后向输出的中红外超荧光最大功率和为91.09 mW。在光纤两端端面角度一样的条件下,反向泵浦输出的中红外超荧光功率要明显大于正向泵浦输出的功率,这是因为在远离泵浦端的光纤部分,泵浦光密度更低,使得激发态吸收过程更弱,亚稳态能级4I13/2上留存了更多的粒子,进而加强了其重吸收过程,使得输出的中红外超荧光效率和功率降低。文中实验中超荧光发射效率低。这是由于所用泵浦光纤为数值孔径是0.46的无芯光纤,所用信号光纤纤芯数值孔径是0.12,远小于内包层数值孔径0.45,大部分泵浦光虽然能被信号光纤内包层吸收,却无法被纤芯中的掺杂离子吸收,从而无法实现有效的超荧光产生。此外,文中使用的增益光纤掺杂浓度低,光纤长度短,也限制了中红外超荧光输出功率和效率的提升。未来可以通过提高光纤掺杂浓度以缓解Er3+能级自终止现象、优化增益光纤长度以提高泵浦光利用率等方法实现功率的进一步提升。

-

文中报道了全光纤结构的中红外超荧光光源及侧面泵浦合束器研制。利用拉锥光纤侧面耦合的原理,在125 μm包层直径的无源双包层氟化物光纤上实现了中红外光纤侧面泵浦合束器的研制,该合束器耦合效率达82.3%,可承受的最大泵浦功率达87.5 W。通过直接在增益光纤上制作合束器,实现了全光纤中红外超荧光光源产生,前后向输出的中红外超荧光最高功率和为91.09 mW(后向输出53.67 mW,前向输出37.42 mW),输出光谱范围从2702 nm覆盖至2830 nm,在中红外超荧光总输出功率为33.03 mW时,获得了108 nm的20 dB最大带宽。文中研制的中红外侧面泵浦合束器及全光纤超荧光光源产生方案不仅可以提高中红外超荧光光源的紧凑性与可靠性,而且为中红外超荧光光源的进一步功率放大提供了良好的解决方案。

Mid-infrared side-pumping combiner and all-fiber superfluorescent fiber source (invited)

doi: 10.3788/IRLA20230101

- Received Date: 2023-02-28

- Rev Recd Date: 2023-04-17

- Publish Date: 2023-05-25

-

Key words:

- mid-infrared fiber source /

- superfluorescent fiber source /

- side-pumping combiner /

- fluoride fiber

Abstract:

DownLoad:

DownLoad: