-

红外热成像仪具有隐蔽性好、抗干扰性强、目标识别能力强、全天候工作等特点,已在工业测温、安防、消防、建筑、复合工程、电力、汽车辅助驾驶等多个方面广泛应用[1]。然而,由于红外热成像仪的工作环境恶劣,工作环境的温度变化会导致红外热成像仪的光轴发生改变,从而影响热成像仪的瞄准精度和整体性能[2],因此,从机理上认识红外热像仪光轴热变形以及通过拓扑优化技术减小光轴的热偏移,对热像仪的整体性能提升十分重要[3-4]。

随着时代的进步,各个行业都对产品的整体性能提出了更严苛的指标,需要在减轻产品质量的前提下提升产品的性能,在需求的推动下,结构有限元仿真技术和拓扑优化技术也相应得到了发展[5-9]。陈俊林等人针对杜瓦柔性外壳结构进行结构热力学分析,验证了低温光学用杜瓦柔性波纹管外壳模型的合理性[10];江帆等人针对星敏感器支架进行了结构热力学分析,证明了该支架能够满足星敏感器定姿精度要求[11];刘仲宇等人针对红外导引头稳定平台主框架进行拓朴优化设计,实现了导引头的轻量化及性能提升[12]。

温度变化会影响热像系统的光学件、结构件以及三者之间会产生相互作用,即光-机-热效应[13],进一步会影响光学系统的性能,因而对光学系统进行无热化设计是必要的。常规的光学系统无热化设计主要考虑了温度对光学件折射率的影响,通过匹配不同热特性的光学件材料来实现消热差的目的[14-16],而对于光机结构变形引起的光学元件轴向移动、偏转、面型变化的影响欠考虑。光机热集成仿真分析方法可以较为全面地考虑光-机-热效应的影响,应用于无热化设计能够取得更好的效果[17]。李欢等人通过光机热集成仿真分析方法分析了红外成像光学探测系统结构在温度载荷下变形机制和成像质量变化机理,指导光学系统安装结构的设计改进和优化[18]。姬文晨等人应用光机热集成分析方法预测热环境对红外光学系统光学性能的影响,为光机系统设计提供了参考[19]。柳鸣等人针对光电对抗稳定平台中的变焦镜头进行了光机热仿真分析,并经过高低温可靠性实验对变焦光学系统的光机结构设计合理性和温度适应性进行了验证[20]。

然而,我国针对热像仪的光轴热稳定性仿真及优化设计的相关技术发展较晚,尚未形成一套可靠的、可以指导设计及提升整体性能的仿真和优化方法,设计人员只能通过反复装调来保证热像仪的光轴偏移量满足设计指标,这种方法并不能从本质上了解影响热像仪光轴偏移量的原因,也就无法通过结构设计提升热像仪的光轴热稳定性[21]。文中以某型红外热像仪整机的光轴热敏感部件——折转镜为仿真分析对象,采用ANSYS有限元仿真软件构建折转镜的结构热力学仿真模型,通过试验验证了该仿真模型的有效性;并针对折转镜座以提升光轴热稳定性为设计目标进行结构拓扑优化设计,优化后的模型进行高低温试验测试,证明了拓扑优化技术提升折转镜的光轴热稳定性的可行性。

-

ANSYS是一个采用有限元法进行仿真模拟的分析软件,有限元法是一种数值计算方法,它将连续体离散化为有限个单元,将复杂模型离散为多个简单的单元模型的集合,通过对每个单元模型进行数学建模和计算,再通过简单单元的节点使得离散化的有限单元相互连接,最终通过求解有限个简单单元的方法实现整个复杂模型的计算。

在进行结构热力学仿真时,需要考虑固体力学与传热学之间的相互作用,即结构变形导致热场分布的改变反作用于结构变形,为了描述这种相互作用,可以建立结构热力学耦合方程,即:

式中:x为结构的位移;M为结构的质量矩阵;C为结构的阻尼矩阵;K为结构的刚度矩阵;F为外部施加的力;v为结构的速度;ρ为物质的密度,Cp为物质的比热容;T为物质的温度;t为时间;k为热导率;Q表示热源;h为热流密度;$ {{Q}} \cdot {{v}} $和$ {{Q}} \cdot {{h}} $分别表示结构和热之间的相互作用。

-

结构的优化设计是提升产品性能的有效手段之一,然而传统的结构设计是基于经验的设计,该方法对于设计对象的变化本质没有充足地了解,所以要实现性能的提升较为困难。然而拓扑优化的本质就是在目标函数和约束条件的共同作用下,通过改变结构的单元密度实现材料的去除与添加,然后进行结构的目标函数计算并以此为基础进行迭代优化,最终实现局部的最优解,其理论基础如下:

式中:φ为梯度投影;β为平滑因子;E为杨氏模量;u为位移场;f为载荷;J为目标函数;σ为应力张量;ε为应变张量。其实质是将离散化单位设置为变密度单元,密度为0则认为该区域为空,密度为1则认为该区域为实体,通过改变优化区域的密度获得目标结构。

-

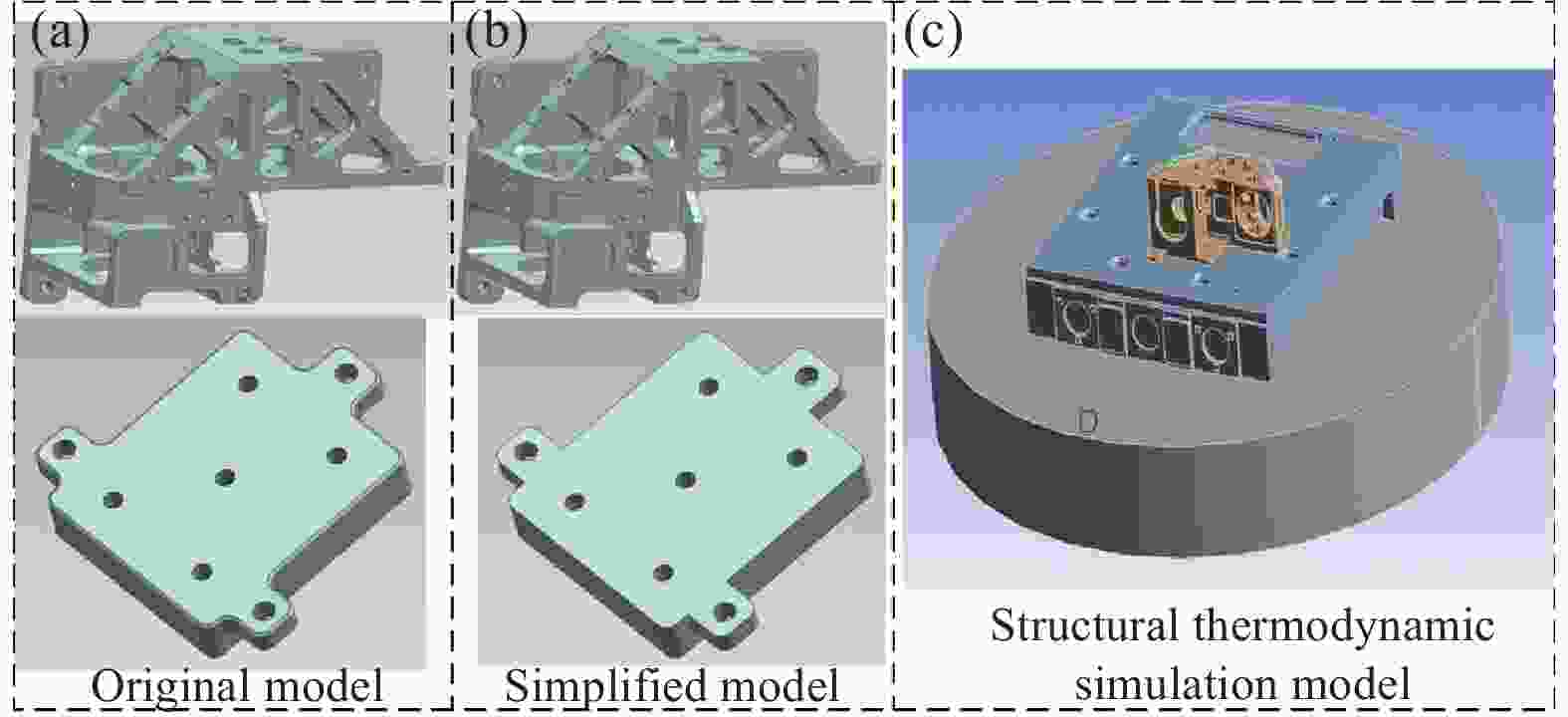

首先将三维模型导入ANSYS软件中进行模型简化,如图1所示,模型简化可以在不影响仿真精度的前提下,提升仿真模型的计算效率和收敛性。由于试验测试过程中采用了高精度温度传感器实时监测被测物体的温度,当温度达到恒温时才测试折转镜的光轴偏移量,整个过程可以看作是稳态过程,因此热仿真过程中不需要考虑流固耦合以及空气对流情况。针对折转镜中的反射镜与反射镜座的连接方式,采用了绑定条件并通过MPC设置模拟螺钉固定区域进行约束;通过在反射镜添加远程点,以实现对指定位置的变形情况的监测;针对折转镜精度要求高、曲率变化大、模型尺寸小等区域,采用四面体网格进行网格细化和分布式划分,共划分344787个单元,598739个节点。

-

图2(a)为待优化的折转镜座三维结构,该模型是经验设计的产物,结构上的减重孔都是对称使用的,并没有针对其使用场景进行针对性设计。如果要针对该模型进行拓扑结构优化,需要先构建如图2(b)所示的原始模型的最大外包络结构,然后以实际加工与装配为设计约束,进行如图2(c)所示的拓扑优化区域的分割,以实现拓扑优化设计模型与经验设计模型的替换。因为变密度法的拓扑优化是通过调整有限元网格的密度实现模型结构的优化的,所以拓扑优化的结果与网格的关联性较弱,容易得到网格无关性结果。

-

折转镜组件主要受到热载荷、重力、螺钉约束以及接触面的摩擦等多种载荷的作用,热载荷主要通过稳态热模块实现,由于热像仪整机的试验测试环境为−40 ℃的低温环境与+55 ℃的高温环境,文中主要介绍一种折转镜组件的仿真及拓扑优化方法,以+55 ℃和−40 ℃的高低温环境为主要研究对象;重力方向指向地心,数值大小依据测试环境而定;螺钉的约束和接触面的摩擦的设置,可通过螺钉实体建模、梁单元和绑定接触等,通过调整参数以贴近试验测试数据为主。

折转镜组件在试验测试过程中固定在高精度旋转台上,仿真模型也模拟该过程,固定约束对象为高精度旋转台的底面支撑柱面;反射镜面与折转镜座采用螺栓连接方式进行固定连接。

由于折转镜座结构复杂,直接采用指定拓扑优化体积的方式进行结构优化会导致折转镜座结构畸变,不适用于提升其光轴热稳定性。文中采用针对折转镜座进行区域分割的方式,划分出合理的优化区域与非优化区域,实现折转镜组件的光轴热稳定性的提升与质量控制。拓扑优化的设计目标是折转镜座的刚度最大化,设计响应为材料体积。

-

针对折转镜组件及其测试工装进行结构热力学仿真分析,得到如图3(a)所示的热变形结果。从图中可以看出,连续体的结构热变形是以固定约束区域为热变形中心(此处变形量通过有限元软件设置为0),逐渐向四周膨胀,远离热变形中心的材料的变形量越大。由此可以得出,该模型的结构热变形最大部分为反射镜组件的上半部分,所以进行拓扑优化时要注意约束上半部分的变形;通过将反射镜表面的变形数据导入光学软件中,得出反射镜在高温条件下的光轴热偏移量为44.5″,在低温条件下的光轴热变形量为87.8″。

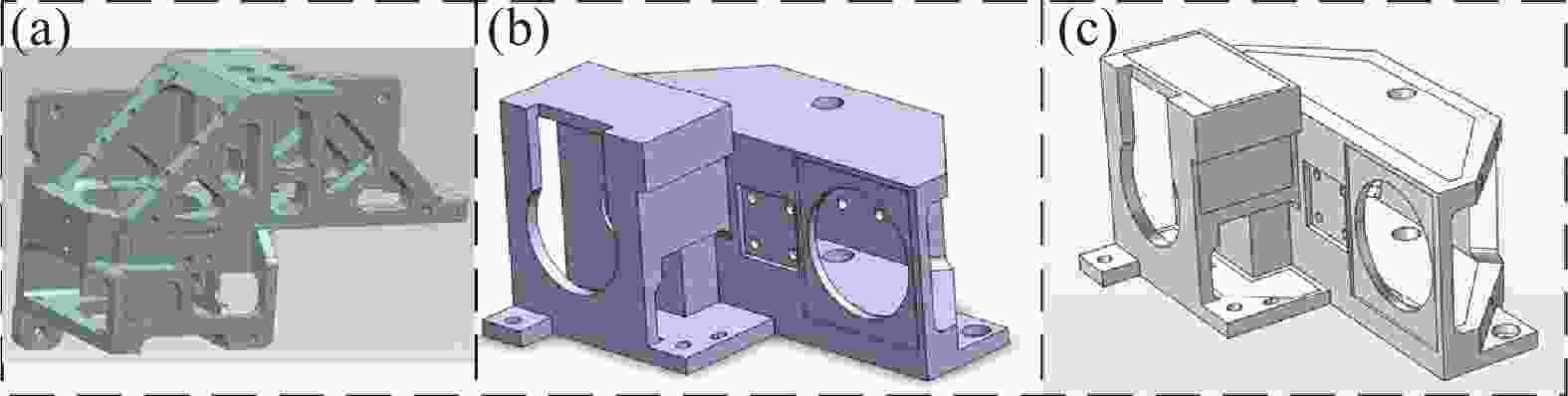

以原始模型的最大外包络模型为拓扑优化仿真对象,利用ANSYS拓扑优化求解器对有限元模型进行求解,经过50次迭代,计算结果收敛,得到了拓扑优化结果如图3(b)所示。其中,偏向蓝色的区域其密度值接近于0,即材料去除的区域;偏向红色的区域其密度值接近于1,即材料需要保留的区域。根据分析结果可见,折转镜座的上半部分材料去除较多,下半部分材料去除较少,说明下半部分材料对于结构的整体刚度的贡献率较大,而上半部分的贡献量较小。根据优化结果与加工工艺进行结构的二次重构,结果如图3(c)所示,实现了不用修改整机结构,可直接进行组件替代的拓扑优化设计。

-

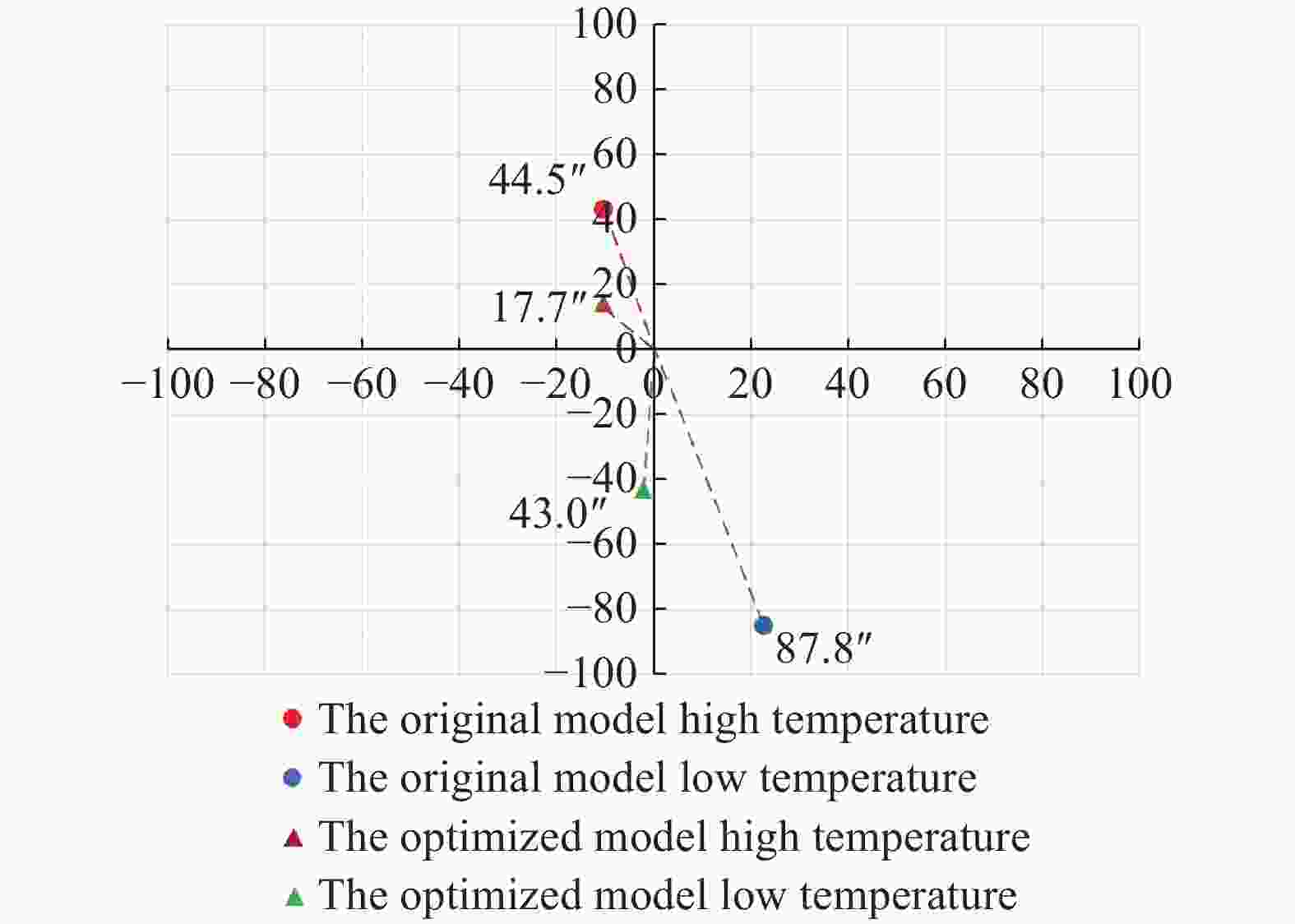

优化前后的两种折转镜的光轴偏移量仿真数据如图4所示。从图中可以看出,折转镜的光轴高温偏移量由44.5″减小到17.7″,减小了60.2%,折转镜座的光轴低温偏移量由87.8″减小到43.0″,减小了51.0%。可见,拓扑优化模型可以实现材料的最优分布,从而实现在质量不增加甚至减少的条件下提升结构性能,有利于提升红外热像仪的轻量化水平和提高红外热像仪的光轴热稳定性,以提高整机的瞄准精度和整体性能。

-

优化前后的折转镜组件被加工和装配在测试工装上,如图5(a)、(b)所示,将整个被测系统放置到高精度旋转温箱中进行折转镜组件的光轴热偏移量测试,测试原理如图5(c)所示,温箱外的光电自准直仪发出光线,通过温箱内的反射镜组件,然后通过温箱外的立方棱镜进行反射,将光线反射回反射镜组件,最后被光电自准直仪接收,得到光轴的偏移量数据。

测试开始前先将高精度温度测试系统粘贴到被测物体的主要监测部位,然后将温箱温度设置到指定温度(+55 ℃和−40 ℃)并进行温度监测,当温度测试系统显示被测物体的温度以及达到目标温度并恒温时,进行折转镜组件的光轴偏移量测试,测试过程重复多次,排除波动较大的偶然误差;将原始模型按照上述试验方法进行重复试验,获得原始模型在相同测试环境下的测试结果,得到如图6所示的测试结果对比图。拓扑优化后,折转镜的光轴热稳定性得到了大幅提升,光轴高温偏移量由46.1″减小到25.5″,减小了44.7%,光轴低温偏移量由92.9″减小到51.0″,减小了45.1%。

为了进一步证明拓扑优化仿真技术的有效性,将优化前后的折转反射镜安装到红外热像仪整机中进行整机的光轴热稳定性测试,在相同的测试环境中进行两种折转镜的光轴热稳定性测试,测试结果如图7所示。安装有优化前后的折转镜的红外热像仪整机的高温光轴偏移量由0.461 mrad减小到0.340 mrad,下降了26.2%,低温光轴偏移量由0.485 mrad减小到0.296 mrad,下降了39.0%。说明拓扑优化技术针对折转镜组件的光轴热稳定性优化是有效的,也为后续的红外整机的光轴热稳定性的进一步提升以及轻量化奠定了基础。

-

文中以结构热力学仿真模型为基础,提高了折转镜在不同温度条件下仿真与试验结果的一致性;采用了基于变密度法的拓扑优化方法,针对热像仪的折转镜组件进行了结构优化设计,以结构刚度最大化为目标函数,获得了折转镜的材料的局部最优分布情况,得到以下结论:

1) 通过对比优化前后折转镜的光轴热偏移量仿真数据,可得到折转镜的光轴高温偏移量由44.5″减小到17.7″,减小了60.2%,折转镜座的光轴低温偏移量由87.8″减小到43.0″,减小了51.0%;

2) 通过对比优化前后折转镜的光轴热偏移量试验测试数据,可得到折转镜的光轴高温偏移量由46.1″减小到25.5″,减小了44.7%,光轴低温偏移量由92.9″减小到51.0″,减小了45.1%;

3) 通过对比红外热像仪整机安装优化前后折转镜的光轴热偏移量试验测试数据,可得到热像仪整机的高温光轴偏移量由0.461 mrad减小到0.340 mrad,下降了26.2%,低温光轴偏移量由0.485 mrad减小到0.296 mrad,下降了39.0%。

研究结果表明,通过拓扑优化技术可以实现在不改变原始结构安装条件的前提下,将目标结构的材料进行局部最优的重新分配,提升目标结构的光轴热稳定性能。该技术可以实现材料的更合理分配,为后续进一步提升热像仪光轴热稳定性以及热像仪的整机轻量化设计奠定了基础。

Simulation and topological optimization of the thermal stability of the optical axis of the infrared imager

doi: 10.3788/IRLA20230358

- Received Date: 2023-06-14

- Rev Recd Date: 2023-10-16

- Publish Date: 2024-01-25

-

Key words:

- structural design /

- topological optimization /

- infrared imager /

- reflective mirror /

- thermal stability of the optical axis

Abstract:

DownLoad:

DownLoad: