-

燃气涡轮发动机自应用以来一直在积极的,持续地发展,目前已在航空,发电,化工,船舶与动力工程等领域获得广泛应用[1],特别在航空动力系统中,燃气涡轮发动机已占据主导地位,其先进性是衡量一个国家工业水平和高科技水平的重要标志之一。涡轮叶片是在高温、高增压比、高推重比运行下受力最恶劣的热端部件[2]。因此,准确地测量涡轮叶片工作温度,保证叶片表面最高温度和温度梯度使其与叶片设计寿命相适应,提高燃机运行安全性与效率;评估叶片的工作状态、识别涡轮潜在的问题、进行辅助、维护计划,对燃气轮机安全运行具有重要意义[3]。

美国、英国、乌克兰等国家早已开展了对涡轮发动机及其部件进行可靠性分析、运行状态监测、故障诊断,发射率及热物性的动态测量等领域的相关研究。Maurizio De Lucia[4]和Carlo Lanfranchi建立环境反射模型,使用简化的二维形状的涡轮叶片和固定位置,计算叶片上每个元素的角系数和叶片离散化后的环境表面,根据稳态条件下交换的辐射热通量准确地评估表观目标发射率和温度。Ketui Daniel[5]通过模拟分析,采用单波长和比率高温计引入的反射误差,计算了不同目标表面发射率、视图因子和环境温度下两种高温计的误差。符泰然[6]基于三维叶片模型的离散化,采用有限元法计算曲面间的角系数和三维叶片上各种波长和实际表面发射率的有效光谱发射率的分布,得出有效的光谱发射率分布在叶片表面上并不均匀的结论。李东[7]用CFD软件根据实际燃气轮机输入参数,对转子叶片和导叶进行温度分布模拟,结果表明,由反射辐射和发射角度引起的温度误差在–23~49 K之间。高山[8]根据涡轮机已知的几何形状和材料的物理性质,离散化不规则曲面,利用数学几何方式计算叶片曲面与相邻热端部件的角系数,建立反射模型。该模型基于叶片的旋转角度和位置,修正了叶片位于不同旋转位置时,由背景辐射引起的测量误差,减少了反射辐射的影响。冯驰[9]采用积分法计算不规则曲面之间的角系数,利用计算流体动力学模拟了叶片和叶片的温度分布,得到了反射辐射误差随叶片间相对位置的变化规律。王天壹[10]通过改变端壁表面发射率,控制端壁辐射热流的静吸收或释放,进而得到不同端壁辐射热流下的叶片表面温度分布,分析了壁面辐射影响下对气膜冷却和叶片冷却性能的影响。

大量文献的研究模型是将叶片拉伸为二维叶片,研究内容主要针对在无谱,叶片几何关系、叶片旋转时角度的变化这些问题上,同时测量手段广泛采用接触式测温,在高温燃气与热端部件构成的高温背景下容易在测温结果中引入不可忽略的误差。端壁对叶片的反射辐射,叶片动静之间的距离也是重要的影响因素。由于热端部件所处的环境复杂,受到壁面及燃气辐射干扰,精准测温十分困难。而采用几何方法的计算缺乏对网格单元进一步精细化分解,考虑网格之间计算的方法也不是很多。因此,在恶劣的工作环境下,最大限度地分析出燃气涡轮发动机叶片工作的温度分布情况是亟待解决的关键问题。

文中的研究重点在于对涡轮叶片采用离散化的三维模型,通过红外辐射测温的方式,结合User Defined Function(UDF)自定义编程开展计算,快速准确求解出空间中细小单元面之间的角系数,考虑端壁对叶片的辐射影响,结合涡轮叶片的工作温度分布情况,讨论有效辐射对涡轮叶片温度测量的影响。该分析基于涡轮叶片红外测温的辐射修正方法,在涡轮叶片红外测温辐射修正方面和叶片误差的精确测量分析方面具有一定的指导意义。

-

在高转速、高温度、空间狭小、测量环境复杂的工作条件下。涡轮叶片传统的测量结果主要受到以下因素影响:1)不同温度下不同的表面发射率。表面形态和材料成分,发射率设定值与叶片表面发射率真实值之间的偏差影响温度测量结果。2)燃气的热辐射干扰。辐射高温计的光路中充满了高温和高压气体,气体不仅吸收叶片的部分辐射能,而且自身会辐射一定量的能量[11]。3)燃烧烟尘沉积物的污染。由于燃料的不完全燃烧,会产生残留的高温热颗粒,当这些热粒子进入辐射高温计的探测光路时,就像小而强的移动辐射源,部分辐射能量将被高温计接收并影响测量结果。4)高叶片速度。5)其他叶片和环境的反射辐射。背景辐射在目标表面的反射和目标自身的辐射相叠加,来自相邻热端部件的辐射所形成的反射量将直接影响测量结果[12]。

-

辐射测温是非接触式测温方法中的一种,通过获取目标表面发出的热辐射能量进行温度测量。如图1所示。

由于燃油,燃煤和燃气的燃烧产物中有一定浓度的二氧化碳,水蒸气等具有相当大辐射能力的三原子,多原子气体,和氢气,氮气等无发射和吸收辐射能力的双原子气体,同时气体辐射对波长有选择性且气体辐射和吸收是在整个容积中进行的,所以通过传统测温方法测温常常会引入不可忽略的误差。采用红外辐射测温能进一步达到测量涡轮叶片工作温度的目的。红外辐射具有:1)响应时间短,反应迅速;2)不影响测量温度场;3)不破坏被测目标结构等诸多优势。随着科学技术的不断发展和交叉融合,红外辐射测温技术也正逐步应用于航空航天领域[13]。

-

Stefan-Boltzmann定律阐述了黑体辐射力与热力学温度的关系[14]为:

式中:$ {{C}}_{{0}} $为黑体辐射系数,值为${5.67 {\rm{W}}/}\left({{{\rm{m}}}}^{{2}}{ \cdot }{{{\rm{K}}}}^{{4}}\right)$;$ {\sigma } $称为黑体辐射常数,值为${5.67×}{{10}}^{{-8}}{{\rm{W}}/}\left({{{\rm{m}}}}^{{2}}{ \cdot }{{{\rm{K}}}}^{{4}}\right)$;该式表明随着温度的上升,辐射力急剧增加。

Max Planck定律解释了黑体辐射能按波长分布的规律:

式中:$ {{E}}_{{b \lambda }} $为黑体光谱辐射力$\left({{\rm{W}}}/{{{\rm{m}}}}^{{3}}\right)$;$ { \lambda } $为波长$\left({{\rm{m}}}\right)$;T为黑体热力学温度$\left({{\rm{K}}}\right)$;e为自然对数的底;$ {{c}}_{{1}} $为第一辐射常量,值为${3.741\;9}\times{{10}}^{{-16}}\;{{\rm{W}} \cdot }{{{\rm{m}}}}^{{2}}$;$ {{c}}_{{2}} $为第二辐射常量,值为${1.}{438 8}\times{{10}}^{{-2}}\;{{\rm{m}} \cdot {\rm{K}}}$;可知黑体光辐射力随着波长的增加,先增大后减小。

对应于最大光谱辐射力的波长$ {{ \lambda }}_{{m}} $与温度T一般由Wien位移定律解释:

光谱辐射力曲线下的面积就是该温度下黑体的辐射力,得出了Stefan-Boltzmann定律与Max Planck定律的关系为:

-

准确求得叶片工作的真实温度关键在于准确描述反射量,在实际测量中,两个表面之间的辐射量传递与两个表面间的相对位置有关。两表面间的相对位置的变化,使得一个表面发出的辐射量到达另一个表面的比例随之变化,为此,必须引入角系数,采用离散化的方法对涡轮叶片网格单元进行角系数的计算,从而达到叶片温度更准确误差分析的目的[15]。

如图2所示,表面1发出的辐射能中落到表面2的百分数称为表面1对表面2的角系数,记为X1,2。同理定义角系数X2,1。

当一个微元表面dA1到另一个微元表面dA2,结合图2所示有:

-

有n个等温漫灰体面组成的封闭系统下,见图3,已知各面温度,求各面有效辐射力,由辐射理论基础,每一个面都可列出三个方程为[16]:

k表面的外部热平衡式:

式中:Q为表面的净热流量(W);q为辐射换热热流密度(W/m2);J为有效辐射力(W/m2);G为投射辐射力(W/m2)。

k表面的有效辐射表达式:

k表面的投射辐射表达式:

联立公式(6)~(8),通过等式代换,若已知各表面面积,表面发射率ε及系统内所有的角系数$ \varphi $,各表面温度T,则可得到有效辐射力计算式为:

式中:$ {k=1,2,3,}\cdots $。由于有n个线性方程,所以使用线性代数的知识可得:

其中,

$ {\delta }_{{k,i}} $为克罗内克算符,则:

则公式(10)可改写成如下形式:

式中:[J]表示有效辐射列矩阵;[A]表示a的方矩阵;[T4]表示温度四次方的列矩阵,由上述理论公式反推导可知T-eff为:

式中:${T\text{-}eff}$表示该工况计算收敛时,有效辐射计算所得涡轮叶片上各网格单元温度。

则定义T-dif为:

式中:$ {T\text{-}dif} $表明叶片网格单元在测量和计算两种方法下的误差情况。$ {T\text{-}wall} $表示涡轮叶片在给定边界条件计算收敛时,此时叶片上各网格单元的温度。

-

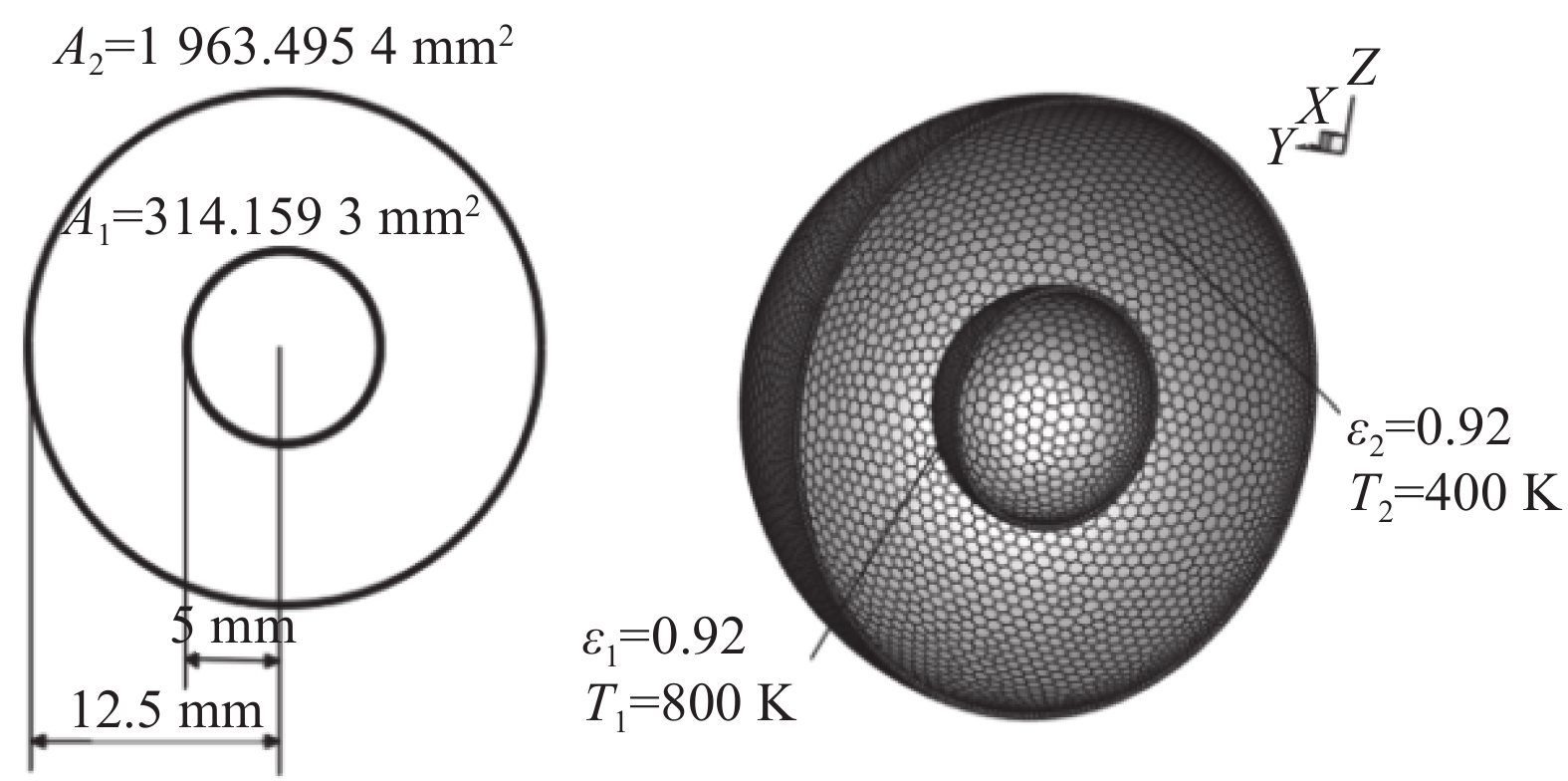

由于在实际有限面组成的辐射换热计算中,各表面有效辐射均匀的情况很少,当采用表面有效辐射均匀假设为基础的计算方法时,就会由计算原理的近似性引起误差,为研究数值计算结果的可靠性,使验证叶片计算的结果更具有说服力,采用大球内腔壁与腔内小球的辐射换热经典模型进行验证计算[12]。

两球均为等温灰体,设定内球面,外球面壁面温度,发射率等相关参数如图4所示[17]。文中通过fluent meshing采用非结构化网格对同心球模型进行网格划分,最小网格尺寸0.024 mm,最大网格尺寸0.63 mm,小球外壁面网格数量911个,大球内壁面网格数量5633个,模型满足计算要求。

由传热学[14]可知,其小球外壁面换热量为:

由公式(6)知$ {q=}\dfrac{{Q}}{{{A}}_{{1}}} $,则:

-

通过数值计算输出,并对角系数进行完整性验证[14]。输出小球外壁面的有效辐射J=3196.452W/m2,经公式(16)、(17)计算所得有效辐射J=3171.33W/m2。由于角系数为一个纯几何因子,取值仅与空间中两表面的形状大小和几何位置相关,与所研究表面的温度和发射率等特性无关。理论上,只要不断的增加网格量,就可以使角系数计算的结果更趋近真实值。则辐射热流量和辐射热流密度将更逼近真实值,该数值模拟计算结果与理论计算结果只相差25.122 W/m2。误差占计算结果7‰,满足验证假设,说明自定义编程计算具有一定的可靠性和可行性。

由于在实验环境条件下,不同温度下不同的表面发射率;燃气的热辐射干扰;燃烧烟尘沉积物的污染;叶片高速度;其他叶片和环境的反射辐射这五大影响因素不能完全规避,也无法就某一个影响因素进行实验验证分析。文中研究内容仅限于对含端壁涡轮导叶的反射辐射,有效辐射进行分析计算,是减少了其他干扰影响因素,特定环境下的数值模拟计算。

-

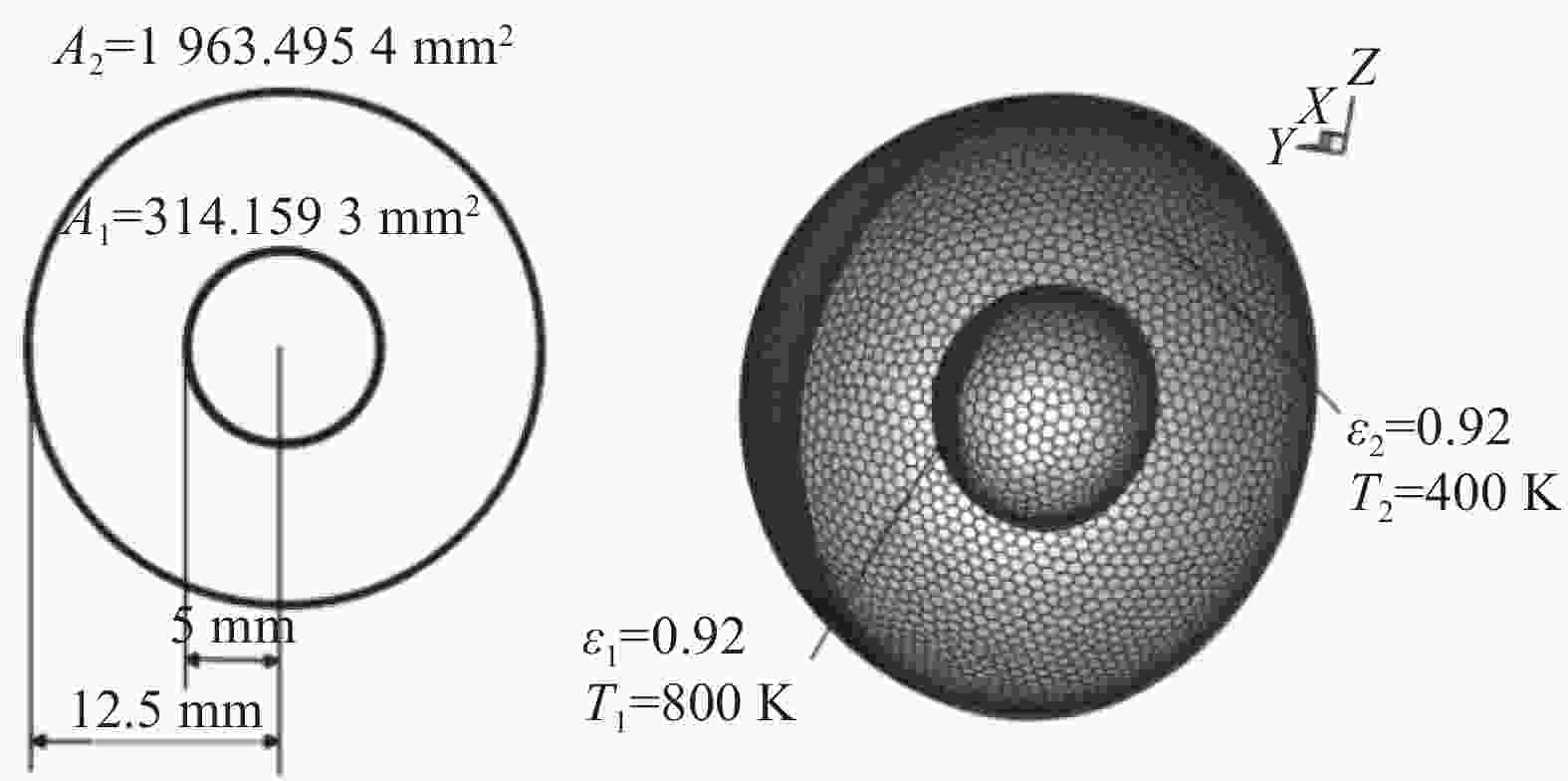

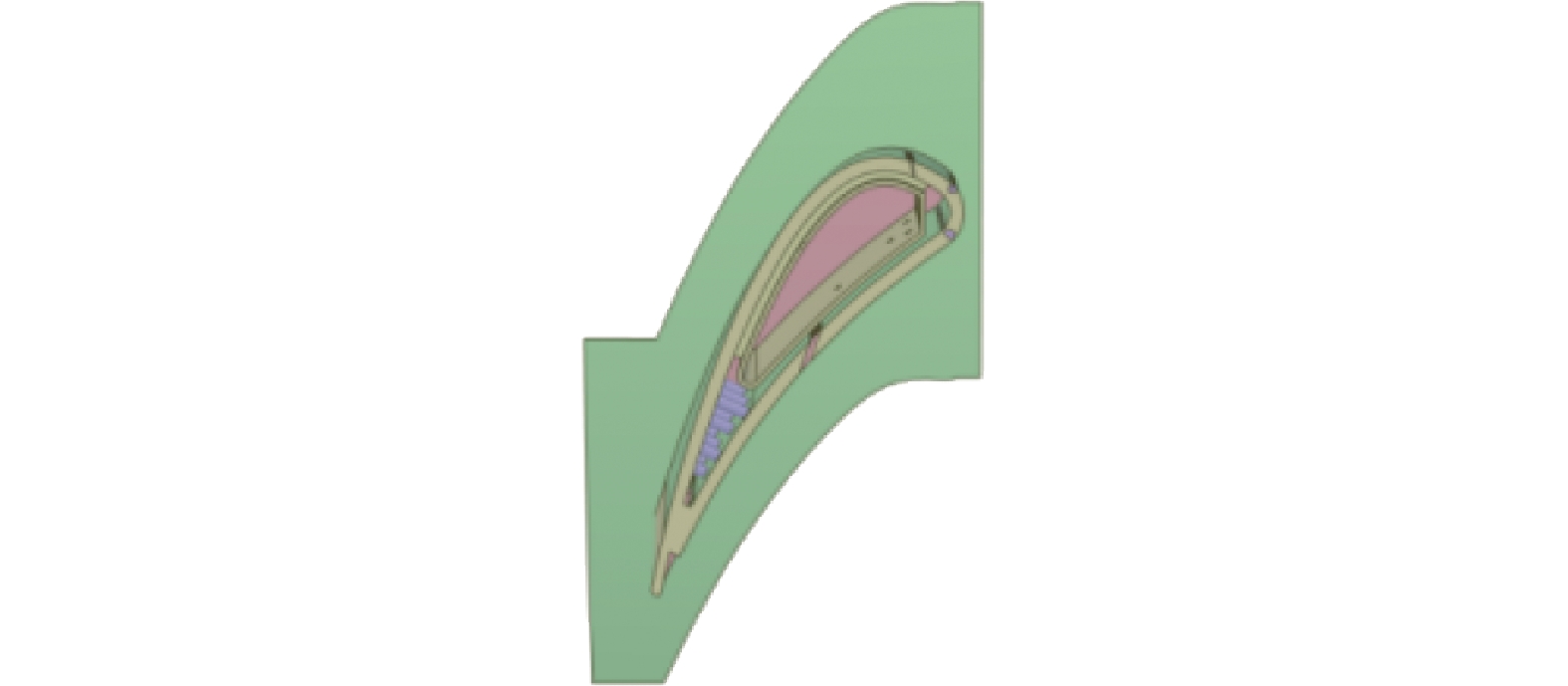

文中选取涡轴发动机中具有复合冷却结构的一级导叶为研究对象,其结构如图5所示,叶片沿中截面切平面内部结构如图6所示。导叶全周期数目为20,计算域中只考虑单个叶片及由叶片所建立的流体域通道,叶片流体通道上下壁面设置为旋转周期边界。叶片叶根及叶顶处同端壁连接受到高温端壁导热作用影响,叶片固体外侧与高温燃气接触,与高温燃气接触的外表面设置为耦合换热边界。叶片中外部冷却主要为气膜冷却,内部冷却为套筒冲击冷却及内部流场对流换热冷却,并在尾缘劈缝前设置绕流柱,改变流动状态来强化对流换热冷却。

二次流从端壁单侧进入叶片内部流体域,端壁外侧与涡轮机匣内部二次流直接接触,从而进行对流—导热换热。计算域的上下壁面设置为旋转周期边界,从而对整个环形叶栅流体通道中叶片外表面的辐射换热进行分析研究。采用非结构化网格对叶片模型进行划分,叶片网格结构如图7所示。

模型采用流固耦合方式进行数值模拟计算,经过网格无关性验证后,模型网格划分数量确定为50万,对涡轮导叶外表面和内表面以及气膜孔区域附近的流体域设置8层边界层,同时设置第一层网格高度为0.05 mm,保证湍流模型及壁面函数所需求的y+值。绕流柱及尾缘劈缝等体积较小的结构进行局部加密,得到更加精细的网格分布。计算工况中辐射模型采用DO模型。离散方法采COUPLE算法,计算过程中的参数离散采用二阶迎风格式。在数值模拟过程中,固体域叶片和端壁材料统一设置为镍;流体域介质为混合气体介质和理想气体。其余边界条件设置如表1所示。

Boundary condition Values Total gas inlet pressure/MPa 1.454 Total gas inlet

temperature/KNon-uniform total temperature Total pressure at

cold flow inlet/MPa1.5 Total temperature of

cold flow inlet/K750 Gas inlet turbulence 25% Cold flow inlet turbulence 5% Table 1. Boundary condition setting

壁面有效辐射计算的矩阵维数数组定义15700×15700,叶片与端壁发射率为0.6,迭代精度为10 e-3,通过获取叶片与端壁的面网格数据,对整个计算域进行循环计算,进而方便地进行各网格单元的黑体辐射力、角系数、克罗内克算符的计算。采用高斯消去法的原理。对公式(13)进行有效辐射的计算,进而输出叶片的有效辐射,表面辐射分布情况,使用TECPLOT进行整合计算并输出误差分布情况。

有关数值模拟过程中辐射相关变量设置应注意以下几点:

1) 经调研叶片壁面辐射相关文献可知[18],燃烧室出口辐射强度约100000 W/m2,可以进而将其折算成温度为1 530 K的黑体辐射强度,参考该值给定导叶进口黑体辐射温度为1 400、1 600、1 800 K;

2)出口辐射温度主要是衡量导叶下游动叶壁面的辐射影响程度,其值基于当地燃气平均温度计算,当发动机处于OEI状态时,燃气温度提升,动叶表面温度提高,定义出口黑体辐射温度为1200、1400、1600 K,来计算出口辐射强度对导叶叶片外表面温度的影响;

3)将发射率的值定义为0.2、0.6、0.8[19]。H2O、CO2、N2和O2的组分占比为0.05、0.1、0.7、0.15。表2给出了计算工况中辐射相关变量的参数设置。

Example

numberEntrance temperature/K Emissivity of wall Radiation

typeExport

temperature/K1 1400 0.6 Wall/Gas 1400 2 1600 0.6 Wall/Gas 1400 3 1800 0.6 Wall/Gas 1400 4 1600 0.6 Wall 1200 5 1600 0.6 Wall 1600 6 1600 0.8 Wall 1400 7 1600 0.2 Wall 1400 Table 2. Example number setting for multi parameter sensitivity analysis of guide vane radiation

-

文中的收敛标准判断需满足以下三个要求:

1)各项残差稳定在10−3以下;

2)叶片表面温度不再随迭代步数变化;

3) UDS输出值趋于稳定。

-

为研究不同进口辐射强度条件下,涡轮导叶在端壁反射辐射下的传热特性的影响,输出其有效辐射分布,改变进口辐射强度,在保证气体组分、叶片发射率、出口黑体辐射温度相同,不考虑燃气辐射影响的基础上选取算例1、2、3,通过计算其在端壁反射辐射情况下的有效辐射分布,以叶片壁面温度(T-wall)分布为基准进行对比研究。

从图8可知,在计算收敛后,其壁面温度分布如图8(b)、(e)、(h)所示,随着入口黑体辐射温度从1400 K提升至1800 K,叶片尾缘和叶片压力面的温度较高。再通过公式(14)反算出在该有效辐射下的温度分布(T-eff),如图8(a)、(d)、(g)所示,在改变进口黑体辐射的温度条件下,对叶片的壁面温度影响主要集中在叶片压力面区域,叶片压力面温度明显高于叶片吸力面区域,其次影响较大的区域主要为叶片前缘区域,这是由于进口黑体辐射温度投入辐射主要照射在叶片压力面及叶片压力面前缘附近,这部分区域接受到了较大的辐射能流。

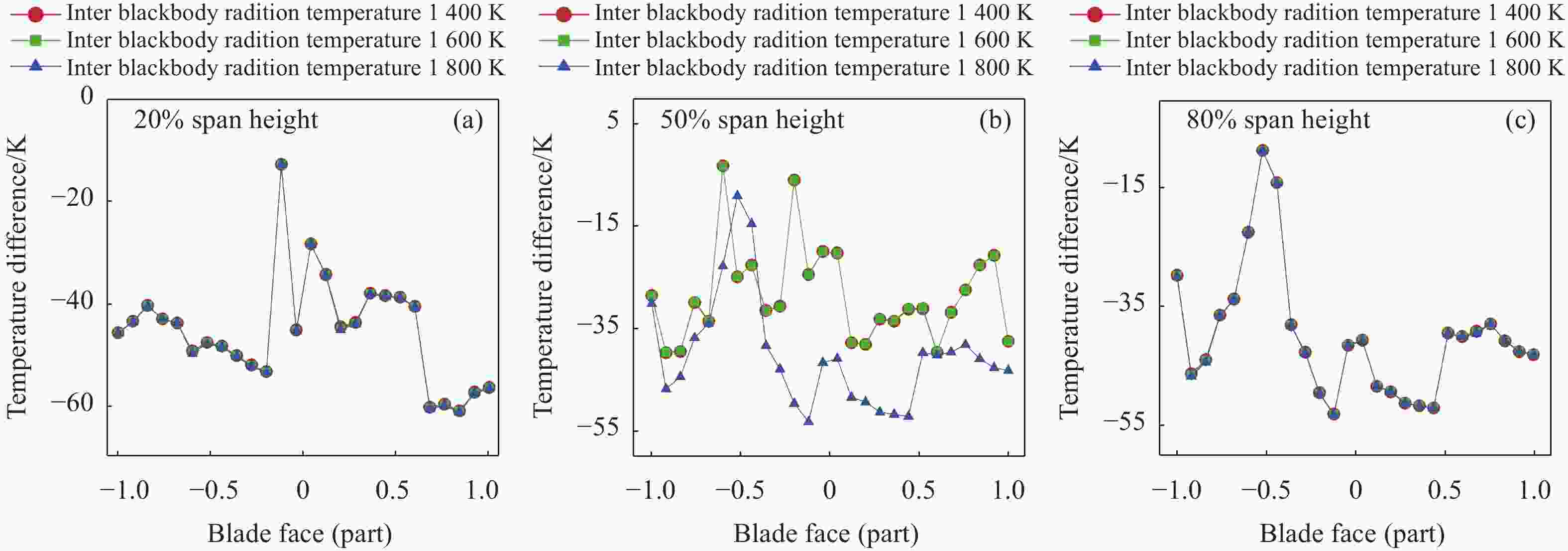

为进一步分析,将误差分布沿叶高方向输出,得到其误差分布如图9所示。笔者将沿不同叶高位置提取到的数据排列在−1~1之间,规定前缘中间位置为0处,则压力面中间位置在−0.5处,吸力面中间位置在0.5处。通过比较在不同进口辐射温度条件下的叶片误差分布,可以定性看出入口辐射温度的提高对于叶片前缘和压力面的温度变化影响最大,尾缘部分次之,且在有气膜孔的区域误差较为明显。由于入口直接受到燃烧室出口燃气辐射的作用,叶片前缘对于入口辐射温度的改变敏感,且尾缘部分冷却措施较少,受到端壁壁温温升的影响,使得此处辐射热流较大,带来较高的温度回升。由公式(15)得误差分布(T-dif)分析,如图8(c)、(f)、(i)所示,在叶片前缘区域计算误差最显著,高达到37.68 K。压力面在主流和二次流的综合作用下,反算出来的误差只在25 K左右。计算的有效辐射分布情况,进一步修正了叶片在不同进口辐射强度条件下的壁面误差分布情况。

-

为研究出口辐射强度条件下对涡轮导叶在端壁反射辐射下壁面温度分布的影响,选取算例4、2、5,其出口黑体辐射温度分别为1200 、1400 、1600 K,通过计算其在端壁反射辐射情况下的有效辐射分布,以叶片壁面温度分布为基准进行对比研究。从图10可知,随着出口黑体辐射温度的升高,辐射热流量占比逐渐增大,吸力面靠近尾缘壁面处存在较为明显的温升。如图10(b)、(e)、(h)所示,叶片吸力面与尾缘受到出口黑体辐射温度的影响更高。出口黑体辐射温度为1600 K时,叶片吸力面及尾缘误差在10 K左右,主要影响区域在叶片吸力面区域,且温升都较小,未能对叶片外表面分布产生较大程度的影响。

为进一步分析,将误差分布沿叶高方向输出,得到误差分布如图11所示。笔者将沿不同叶高位置提取到的数据排列在–1~1之间,规定前缘中间位置为0处,则压力面中间位置在–0.5处,吸力面中间位置在0.5处。在发动机实际工况下,下游动叶的等效黑体辐射温度远小于1600 K。对于文中计算工况而言,只在吸力面尾缘部分辐射能流较大,因此出口黑体辐射温度的变化对于涡轮导叶的影响较小。

-

叶片表面发射率是研究金属吸收和发射辐射的重要参数之一。由于金属叶片表面发射率受温度影响较大,加入辐射会使叶片外表面温度产生较大变化,叶片热侧表面受到来自其他壁面辐射的来源主要由相邻导叶、动叶及相邻端壁组成。

文中叶片端壁未设置冷却措施,所以其温度高于相邻导叶外表面温度,辐射热流更大,由相邻端壁发射和反射的辐射热流会对叶片热侧接收热辐射产生一定程度上的影响。选取算例6、2、7,三个算例中叶片的表面发射率分别为0.8和0.6和0.2,通过计算其在端壁反射辐射情况下的有效辐射分布,以叶片壁面温度分布为基准进行对比研究。

当壁面发射率从0.8、0.6、0.2递减时,叶片压力面前缘区域的温度受发射率的影响较小,有效辐射反算的温度误差分布如图12所示。发射率越大,其在叶片压力面的腮区处的误差也越大。为进一步分析,将误差分布沿叶高方向输出,得到误差分布如图13所示在叶片前缘处的影响较叶片中部区域影响更大,叶片压力面区域较吸力面影响次之。笔者将沿不同叶高位置提取到的数据排列在–1~1之间,规定前缘中间位置为0处,则压力面中间位置在–0.5处,吸力面中间位置在0.5处。

由于气膜孔在前缘位置排布,相较叶片本身角系数较大,在压力面及吸力面气膜孔附近温度变化更为剧烈,叶片表面发射率的改变使叶片可以接收更大的辐射热流,在发动机实际工况下,叶片通道内环境温度较高,由于金属材料的发射率对温度敏感,且随温度的升高而增大,发射率的变化会对于叶片表面温度分布产生较为明显的影响,在高温时,热辐射对于叶片外表面温度变化的影响更大。

-

通过对端壁—叶片模型进行有效辐射和误差的计算,讨论多种辐射因素改变的情形下,对涡轮导叶在端壁反射辐射影响下的传热特性影响进行分析和研究。

1)通过同心球验证模型,验证了UDF自定义编程在同心球封闭腔辐射换热计算的可行性,该方法在涡轮叶片等类似的三维曲面进行网格单元角系数等复杂的计算方面有优势,输出的叶片有效辐射分布能准确分析出叶片在工况下所受到的辐射能流分布情况,对评估叶片温度具有重大意义。

2)当进口黑体辐射温度在1400~1800 K之间,表面发射率为0.6时,进口辐射强度是对叶片换热影响最大的因素,通过输出有效辐射和误差的分布规律,进一步论证进口辐射温度影响区域主要是叶片前缘区域。

3)出口黑体辐射温度的变化对于涡轮导叶的影响较小。温度影响区域主要为叶片前缘区域,而反算的温度误差不超过40 K。其对真实工况下叶片外表面换热量的影响程度有限,在真实工况下可以近似忽略其对叶片表面温度及换热热流量带来的影响。

4)叶片表面发射率与温度成正相关,当叶片表面发射率增大时,叶片表面温度随之均匀升高。

Research on the error influence mechanism of infrared temperature measurement of turbine guide vanes with end walls

doi: 10.3788/IRLA20230371

- Received Date: 2023-06-19

- Rev Recd Date: 2023-11-01

- Available Online: 2024-02-04

- Publish Date: 2024-01-25

-

Key words:

- turbine blades /

- numerical simulation /

- radiation heat transfer calculation /

- radiation characteristics /

- reflected radiation /

- view factor

Abstract:

DownLoad:

DownLoad: