-

As a zero bandgap material[1], graphene is difficult to realize switching characteristics directly in application[2]. Therefore if used in field effect transistor devices, the gating effect of graphene is extremely limited. At present, one approach is to turn graphene into a strip with tens of nanometers in width in the transverse direction afterunfolded as a flat plane, that is, graphene nanoribbon (GNRS), so as to form a quasi-one-dimensional nanosystem[3]. In this way, the electrons are transversely confined, the energy gap is opened, and a high on/off ratio at room temperature is realized. Then it can be used as semiconductor conductors in field-effect transistors[4-5]. The previous reports show that graphene nanoribbons have high magnetoresistance and good magnetoelectric properties[6]. Due to the unique structure, electronic properties and broad application prospects in electronic and spintronic devices, GNRS has attracted extensive attention in the past decades[7-12].

At present, there are many synthesis methods of GNRS, including graphene photolithography[6], organic synthesis[7], SiC epitaxy growth[8], chemical vapor deposition[9], plasma etching[10], and longitudinal dissociation nanotubes (MWNTs)[11], etc. Longitudinal dissociation of MWNTs leads to a high yield of graphene nanoribbons, which is one of the main methods to prepare graphene nanoribbons. Kosynkin et al. opened nanotubes along the axis with strong oxidation of potassium permanganate and sulfuric acid mixed solution[12]. Jiao et al. prepared graphene by argon plasma cutting along the axis[13]. However, graphene nanoribbons prepared in this method contain high proportion, which also reduces the properties of graphene nanoribbons[14-16]. Kumar et al. prepared axially opened graphene nanoribbons by pulsed laser irradiation of multi-walled carbon nanotubes[1]. This physical method can avoid oxidation. Its main concern is the formation of graphene bands, but it does not discriminate against the state of carbon nanotubes that have not been dissociated, nor does it measure electrical properties. At the same time, the changes in surface morphology and structure of carbon nanotubes mainly depend on the parameters of laser processing[17], and the related research on changing or regulating the surface morphology of multi-walled carbon nanotubes by adjusting laser parameters, still needs to be further explored.

Here, a single-step method to unravel multi-walled carbon nanotubes by laser irradiation is reported. This method can produce GNRs efficiently and without pollution. The excimer laser irradiation of multi-walled carbon nanotubes (MWCNTs) was used to dissociate MWCNTs. The surface morphology of MWCNTs was investigated by changing laser energy and irradiation time. The graphene properties were characterized by Raman spectroscopy. Finally, the conductivity of MWCNTs was measured by a semiconductor parameter measurement system.

-

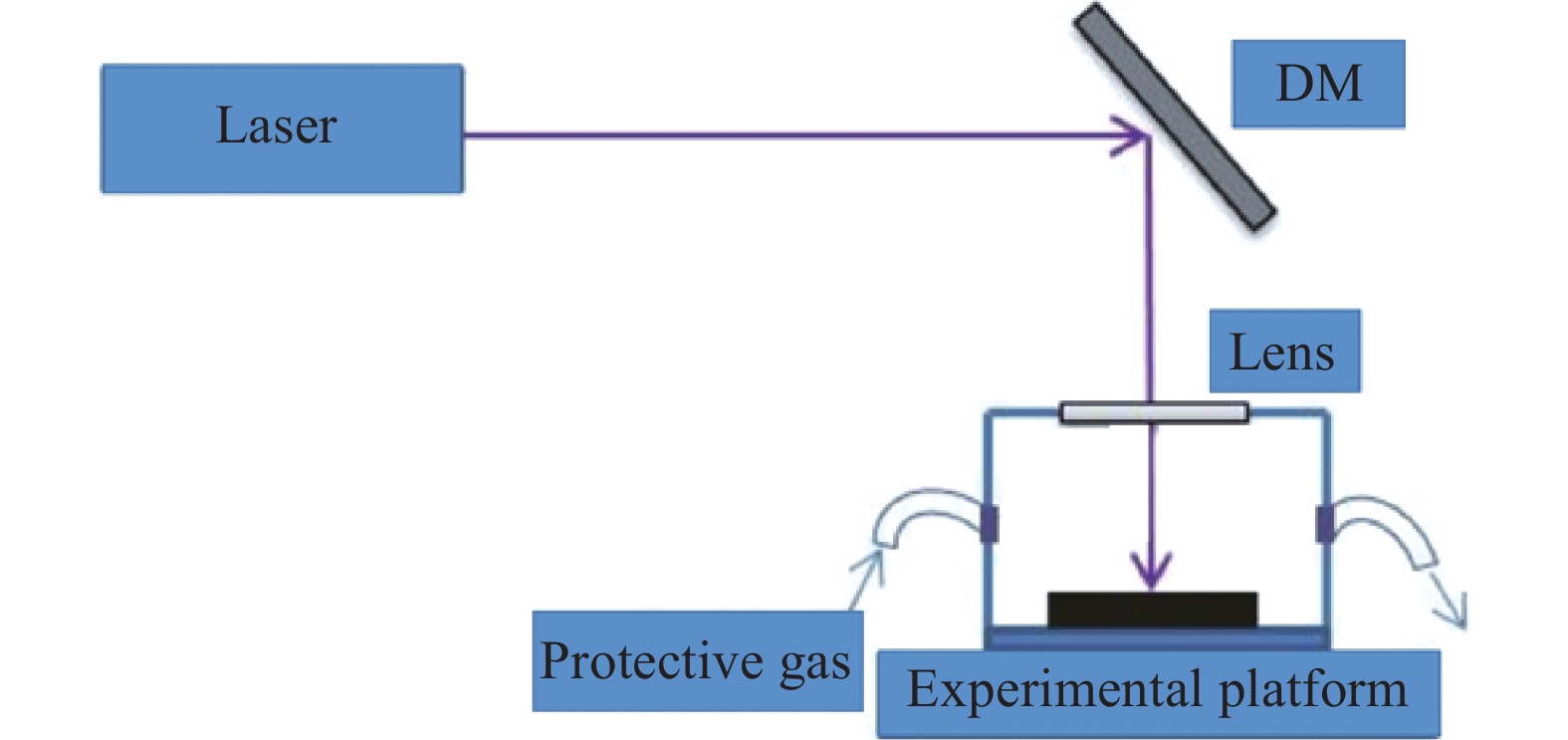

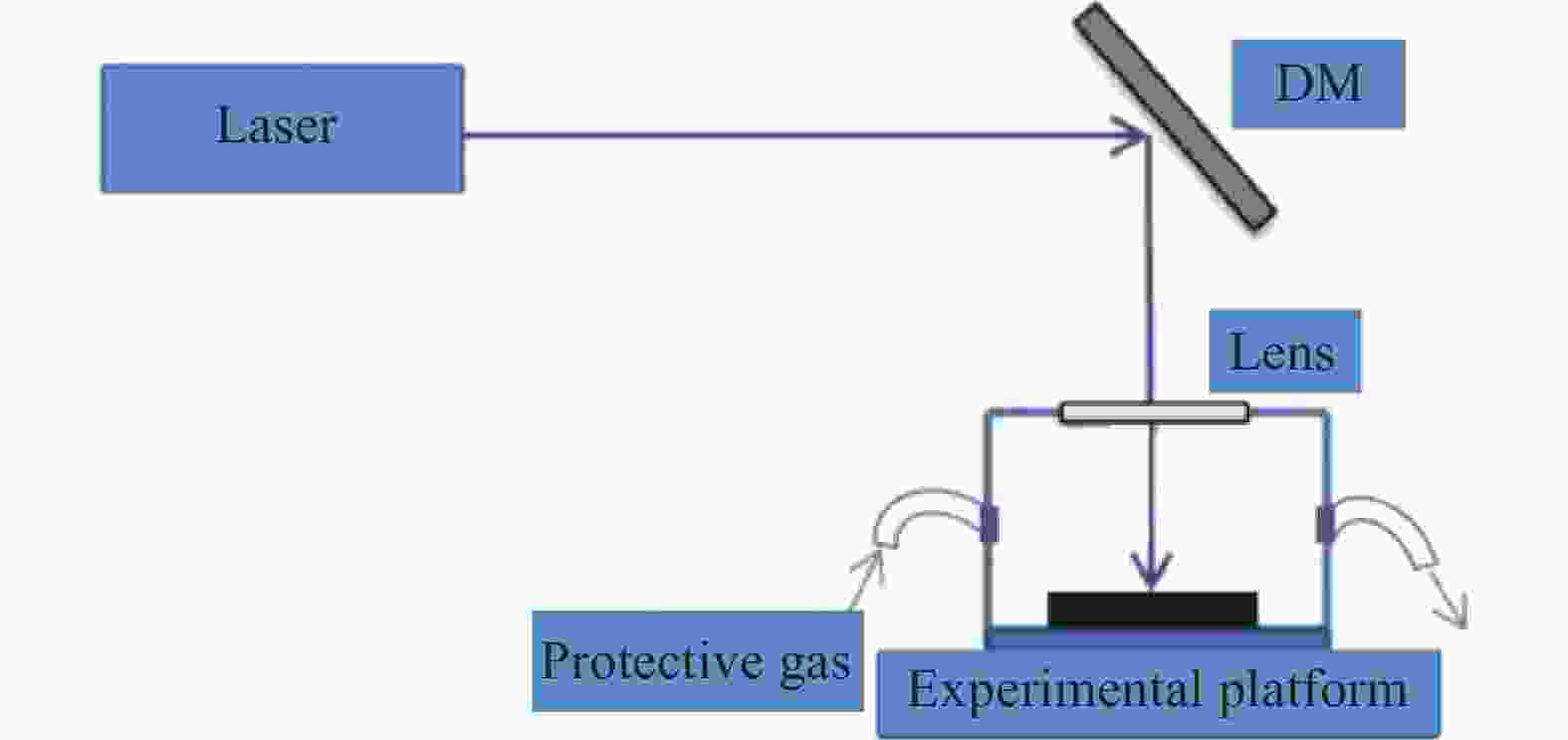

The experiment scheme is shown in Fig.1. The excimer laser used in the experiment is Lambda-Physik (LPX 305iF, Germany). The laser buffer gas is Ne with working gas of KrF. The emission wavelength is 248 nm with the pulse width 30 ns and repetition rate in the range of 1-50 Hz. The single pulse energy of the laser is adjustable with a maximum energy of 800 mJ. The spot size applied is about 35.4 mm × 16.4 mm.

The sample graphite target was prepared by the deposition of MWNTs suspension on a polished silicon wafer. Firstly, the silicon substrates were thoroughly cleaned by deionized water-isopropanol-alcohol-acetone-alcohol. The 1.5 mL of water dispersion (0.2% of dispersant concentration) of 1 mg/mL multi-walled carbon nanotubes were added to 98.5 mL isopropanol, and then 10 mg Mg(NO3)2·6H2O was added to ultrasonic vibration for 10 minutes to obtain uniform and dispersed electrophoretic solution[18]. MWNTs thin films were deposited on silicon wafers by electrophoresis. The thickness of MWNTs thin films was 200-250 nm.

Oxygen and nitrogen in the air will react with carbon in laser irradiation, causing adverse effects[19]. Then inert gas protection is needed. Ar is chosen as the protective gas and the flow rate is 10 L/min. The inert atmosphere in the sealing device is ensured by ventilating for 5 minutes before irradiation[20]. For knowing the laser influence affection upon the CNT film, the excimer laser output single pulse energy is 150, 250, 350, 450, 550 mJ in different irradiation experiments at the repetition rate of 25 Hz, pulse number is 50. The thickness and surface roughness of carbon nanotube films were measured by the optical profiler (Wyko NT1100). A scanning electron microscope (SEM) is used to observe the microscopic morphology (Hitachi S4800). Raman spectroscopy of graphene was characterized by Raman spectrometer (Jobin Yvon's T64000). Lastly, the I-V characteristics of carbon nanotube films were measured by a semiconductor parameter measurement system (Weida Technologies Co., Ltd., PDA-FS360).

-

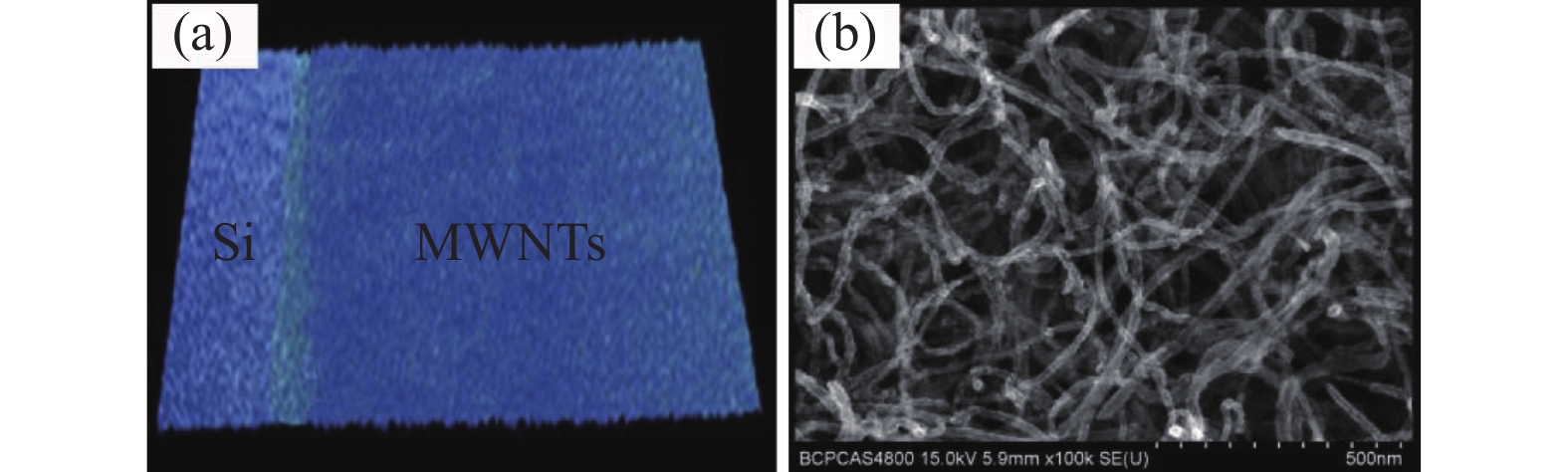

The macro-morphology of carbon nanotube films was measured by the optical profiler. As shown in Fig.2(a), the film thickness is uniform, and the shape is regular. The SEM of MWNTs without laser irradiation shows that the wall of MWNTs is smooth and uniform, and no obvious defects and damage are observed. Its diameter is about 20-30 nm and has a large aspect ratio.

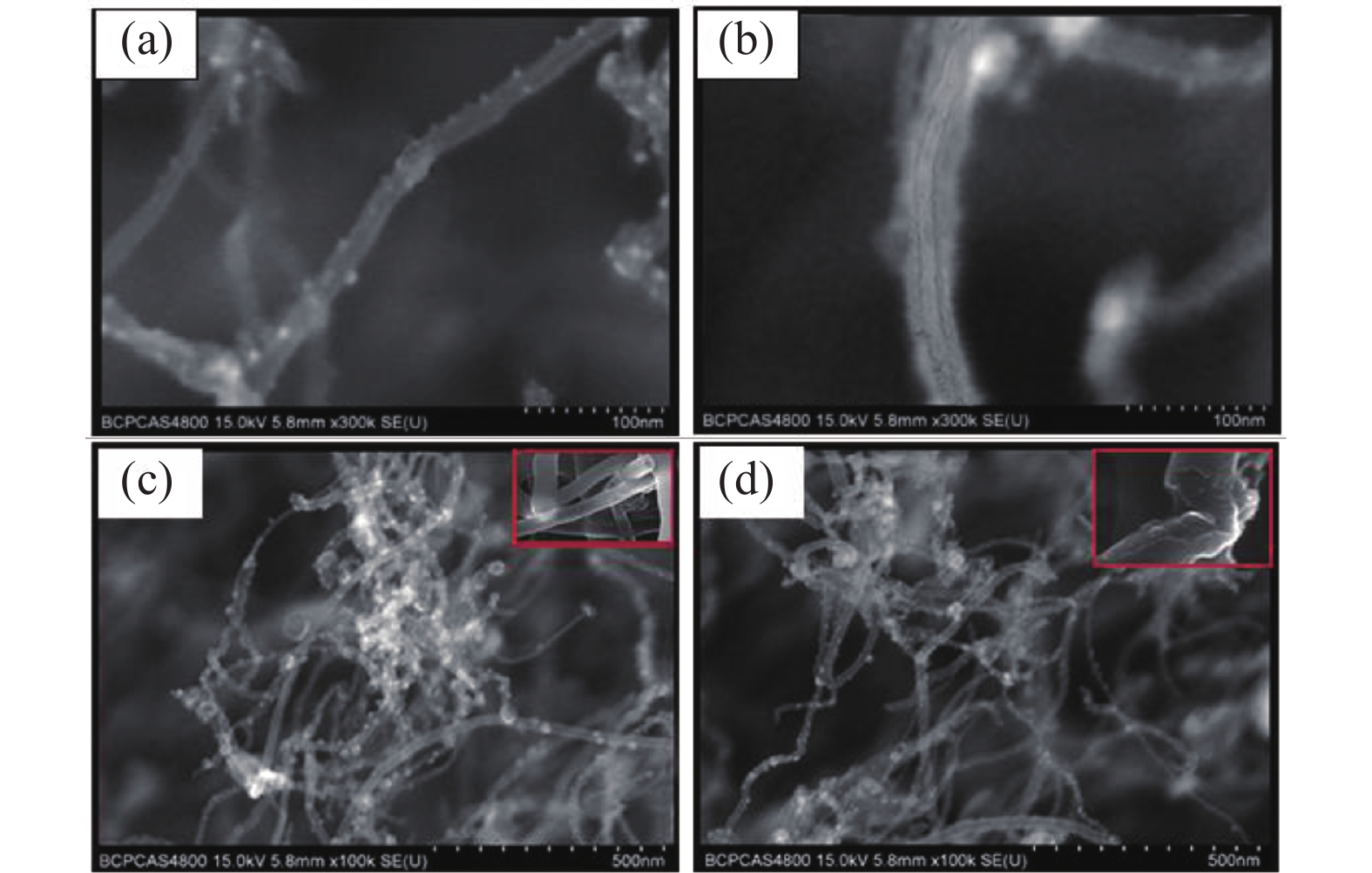

The SEM images of multi-walled carbon nanotube films irradiated by excimer laser (Lambda-Physik LPX 305iF/248 nm/30 ns/50 pulses) are shown in Fig.3. The laser energy is adjusted in the range of 150-550 mJ to test its role in opening nanotubes. As shown in Fig.3 (a), carbon nanotubes were not destroyed when irradiated with 150 mJ. The diameter of carbon nanotubes was 20-30 nm. Figure 3(b) is an SEM image of GNRS obtained from carbon nanotube films irradiated by 450 mJ laser. The width of GNRs is about 70-90 nm. It can be seen that the excimer laser irradiation can well unravel carbon nanotubes to form graphene nanoribbons. As can be seen from Fig.3(c): The wall morphology of 150 mJ irradiated tube is similar to that of MWNTs without laser irradiation, and no dissociation occurs. (2) The Outer wall of MWNTs fused and combined with each other, and there is a connection at the overlap. Figure 3(d) shows that for undissociated MWNTs at 550 mJ, the wall of MWNTs is severely damaged due to thermal accumul, and the aspect ratio of MWNTs is severely reduced, resulting in aggregation of carbon nanotubes.

Figure 3. SEM after laser irradiation with energy of (a) 150 mJ, (b) 450 mJ, (c) 250 mJ, and (d) 550 mJ

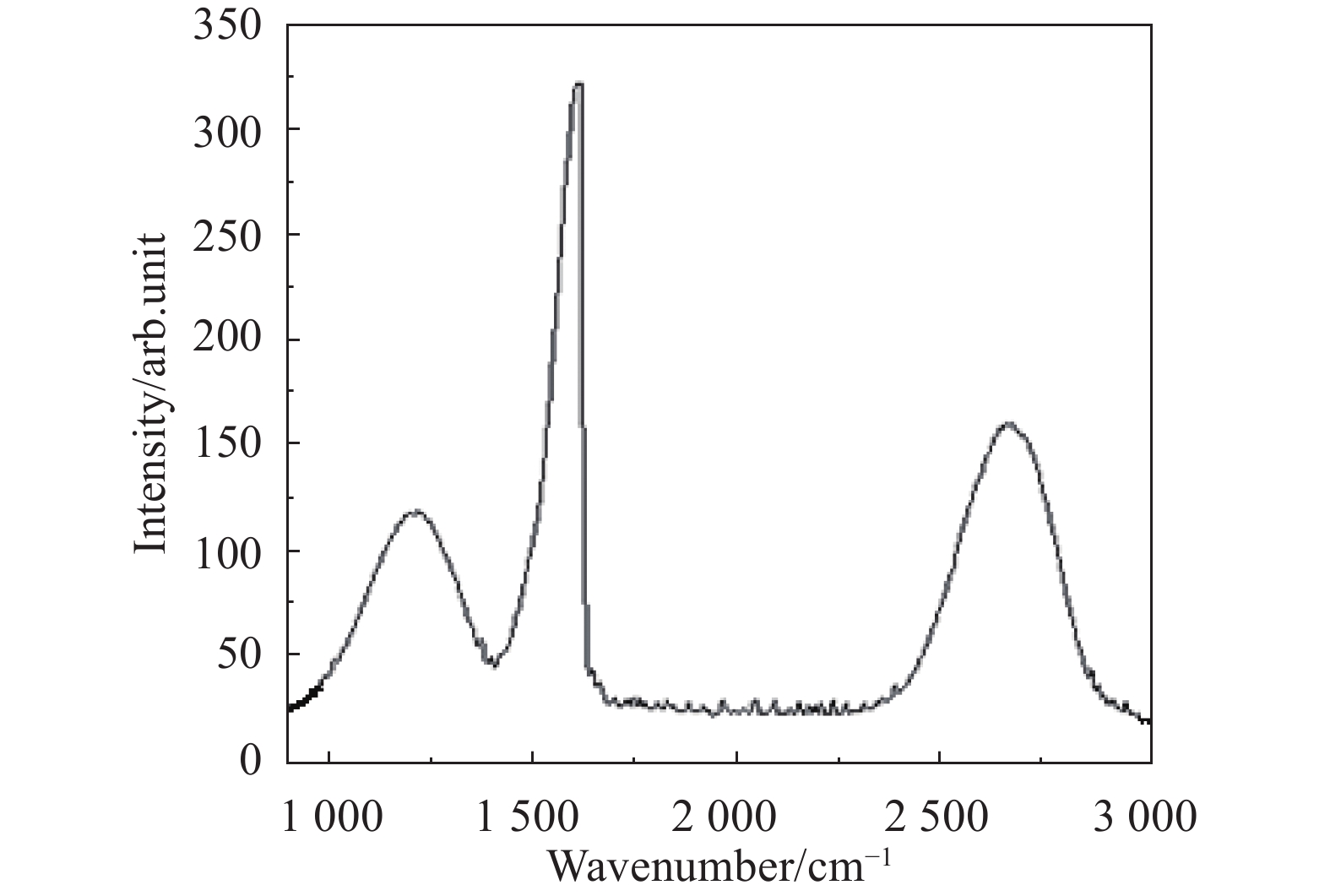

Raman spectroscopy is one of the important means to characterize the quality and defects of carbon nanotubes and graphene[21]. The defect peaks (D peaks) of carbon nanotubes near 1 330 cm−1 come from their structural defects, such as carbon nanotube particles adsorbed on the wall, amorphous carbon, and other nano-sized microcrystals[1]. The peak of carbon nanotubes (CNTs) near 1580 cm−1 is graphite peak (G peak), which is generated by the graphite base surface (wall of CNTs). As shown in Fig.4, Raman spectra of MWNTs without laser irradiation show G-band characteristics due to tangential mode, and D-band and 2D-band characteristics due to defects.

Raman spectrum G band is sensitive to the displacement of Fermi level[22]. The typical Raman spectra of GNRs are shown in Fig.5. Compared with MWNT, the intensity ratio of D band to G band (ID/IG) in GNRS increased significantly with the increase of dissociation. In MWNTs, ID/IG is 0.42, while in GNRs irradiated by laser, ID/IG is 0.7-0.9. The ratio of I2D/IG in MWNTs is higher than that in GNRs. In MWNTs, the ratio of I2D/IG is 0.5 and GNRS is 0.15-0.4. It can also be judged that more GNRS will be produced with the laser energy of 350-450 mJ.

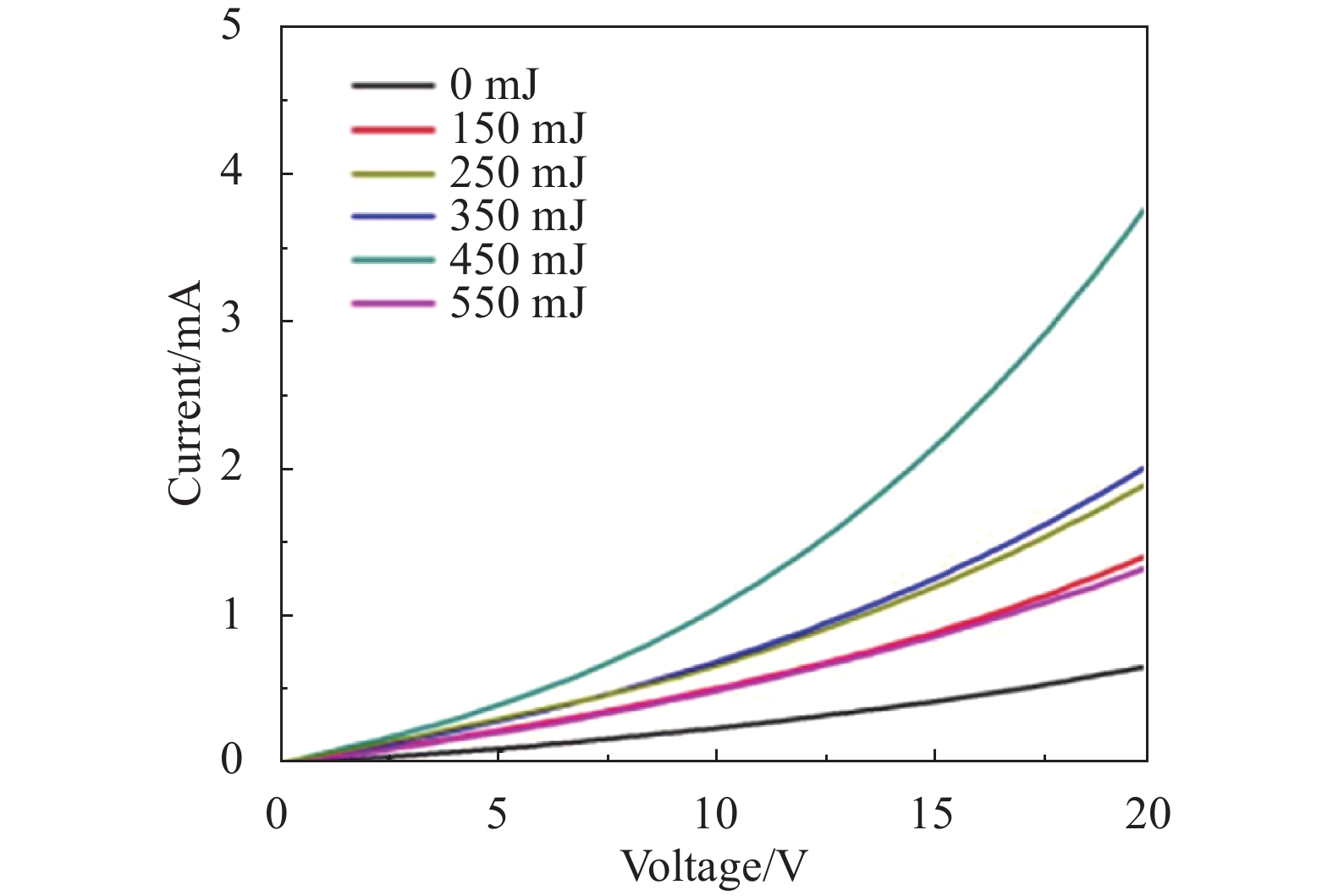

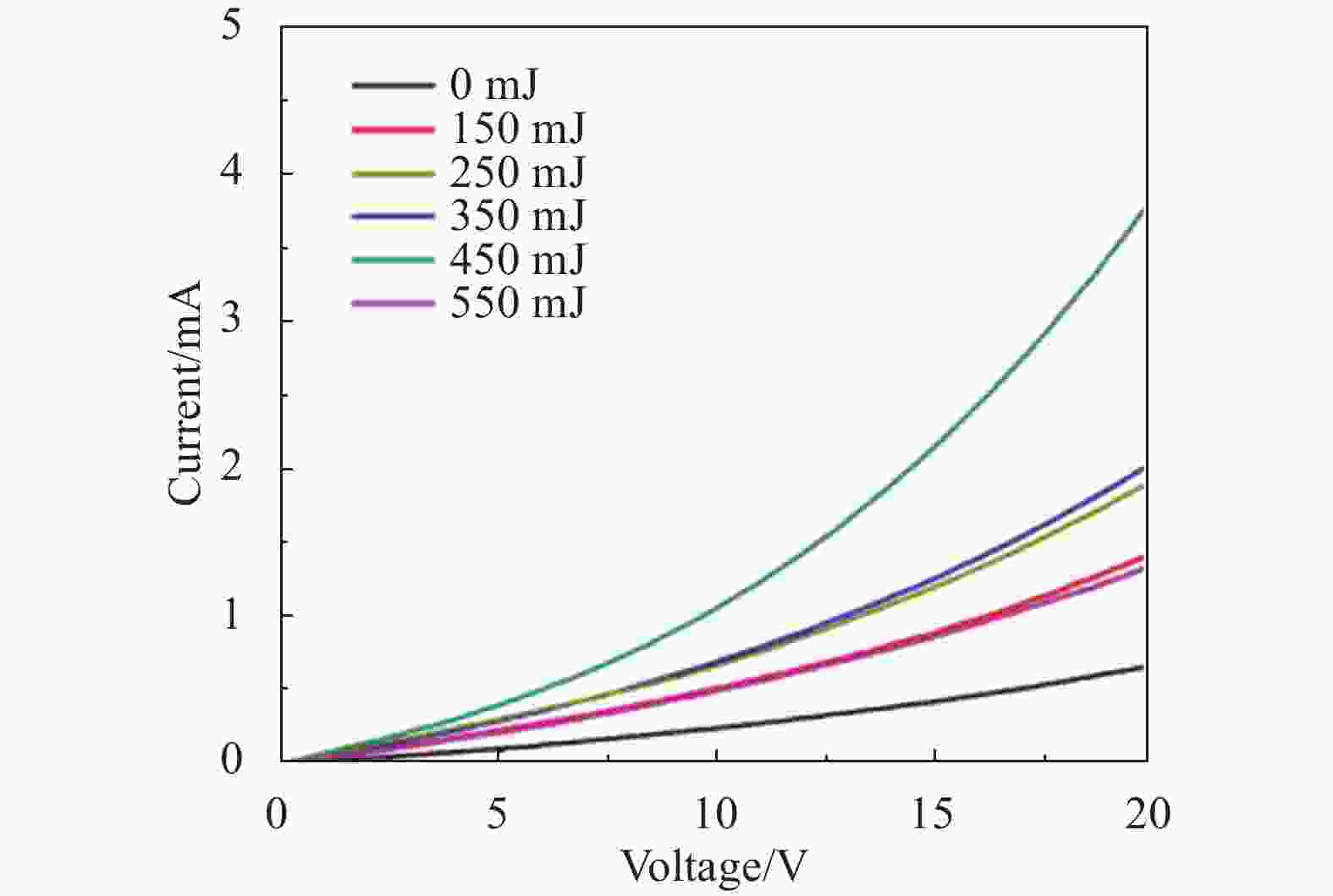

By testing the I-V characteristic curve of the film, it can be seen that the conductivity of the film is greatly enhanced after laser irradiation, especially after 450 mJ laser energy irradiation (see Fig.6). This is because excimer laser irradiation can effectively open carbon nanotubes to form GNRS and improve the conductivity of the films. However, when the laser energy increases to 550 mJ, the conductivity of the films decreases sharply due to the damage of thermal accumulation.

-

In summary, our study shows that the excimer laser irradiation of carbon nanotubes thin films is a simple method for preparing graphene nanoribbons without surface pollution. When MWNTs are irradiated, the defect location is easy to reach a high temperature that leads to longitudinal dissociation. With the pulse energy of 450 mJ, the film disassembled at the best result and the conductivity is improved significantly. In addition, when the laser energy is 150 mJ, no carbon nanotubes are opened, and the connection of carbon nanotubes can be observed. At 550 mJ, the thermal accumulation of the film was seriously damaged, and the conductivity of the film decreased sharply.The result shows a certain significance for the efficient preparation of 2D graphene ribbon structure materials.

Laser-induced transformation of carbon nanotubes into graphene nanoribbons and their conductive properties

doi: 10.3788/IRLA20200298

- Received Date: 2020-04-06

- Rev Recd Date: 2020-05-17

- Available Online: 2020-09-22

- Publish Date: 2020-09-22

-

Key words:

- carbon nanotubes /

- graphene /

- excimer laser /

- Raman spectroscopy

Abstract: GNRs can be readily produced by unzipping the nanotubes because CNT structure can be analogically considered as graphene sheets rolled up. This is a special 2D graphitic structure performing the exceptional properties. Due to the unique structure and the outstanding properties, GNRs have been used in a vast range of applications, including transistors, optical and microwave communication devices, biosensors, chemical sensors, electronic memory and processing devices, nano electromechanical systems, and composites. The morphology of the fiilms was observed by scanning electron microscopy (SEM), and the properties of graphene were characterized by Raman spectroscopy. The conductivity of the fiilms was measured by a semiconductor parameter measurement system. Raman spectroscopy showed that the Raman characteristics of graphene characterized by optimized process were enhanced. Laser energy and irradiation time were two important parameters for the preparation of graphene from carbon nanotubes. In this study, to open carbon nanotubes by laser, graphene nanoribbons were produced by excimer laser irradiation of carbon nanotubes thin films. The experimental results show that, with the laser energy 150 mJ, the carbon nanotubes are not opened while the connection is observed. With the energy 450 mJ, the carbon nanotubes can be effectively destroyed, and graphene strips can be partially opened to form. At this time, the conductivity of the fiilm reaches the maximum value. Due to the thermal accumulation effect, a large number of porous structures appear on the wall of carbon nanotubes.

DownLoad:

DownLoad: