-

清洗,就是利用某种清洗媒介以物理、化学或生物方式将污染物从物体表面去除,恢复物体原貌的过程。清洗过程存在四个要素:(1) 基底材料,如半导体线路板、建筑物、工件等。(2) 污染物或附着物(统称污染物):因自然或人为原因,在基底材料表面上附着的油污、铁锈、灰尘、油漆等。附着有污染物的基底材料,称为清洗对象。(3) 清洗介质:用来将污染物从清洗对象的表面去除,如水、化学试剂、铁砂、激光、电磁波等。(4) 清洗力:因机械、溶解、表面活性、化学反应等作用,在清洗对象和清洗介质之间存在的力,通过该作用力实现清洗过程。

清洗技术可分为两大类:(1) 物理清洗技术,利用力热声光电等物理原理,依靠机械摩擦、加热、超声波、高压、冲击、紫外线、蒸汽等,去除物体表面上的污染物,清洗过程中没有(或者可以忽略)化学反应。如高压水射流、电脉冲、超声波、喷丸等技术。(2) 化学清洗技术,利用化学试剂与污染物发生化学反应,或利用电解技术,将污染物去除。如化学试剂清洗、电解清洗、生物清洗等技术。此外,等离子体清洗技术既有物理反应又有化学反应。

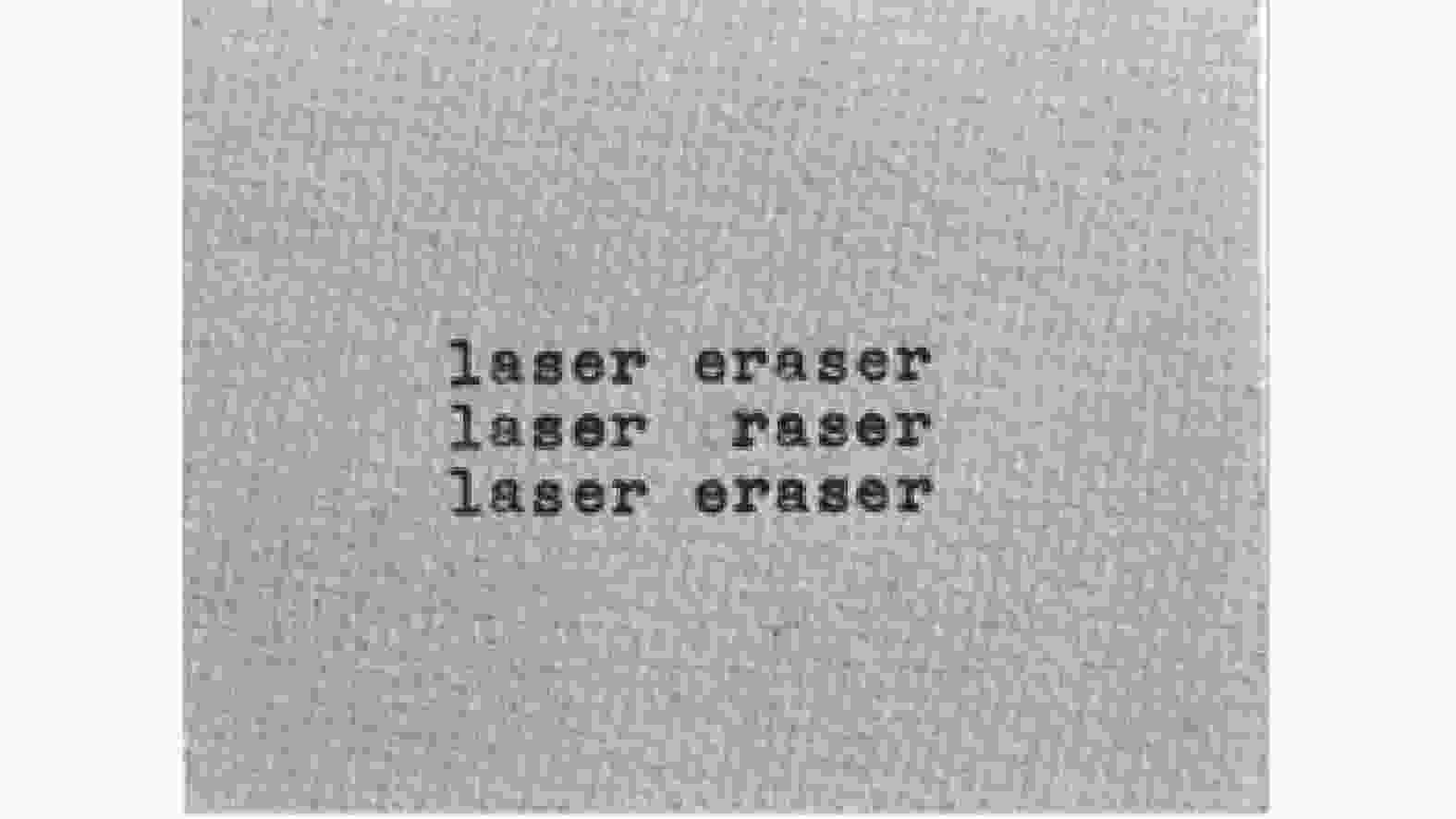

激光清洗,是将激光照射清洗对象,通过热振动、烧蚀等过程使污染物离开基底表面的技术,可归于物理清洗技术,其研究最早可溯源到20世纪60年代。1965年,诺贝尔奖获得者肖洛(Schawlow)用脉冲激光照射有字(油墨印刷)的纸,纸面的墨色字体快速汽化,而纸本身没有损伤。他第一次提出了“激光擦(laser eraser)”术语,如图1所示[2]。1969年,贝德尔(Bedair)等人[3]用调Q激光清除镍表面的氧和硫污染,提出了激光清洗这一概念。

1973年,阿斯姆斯(J·Asmus)团队最早报道了激光文物清洗[4],他们对多种文物进行了激光清洗,包括达芬奇壁画、雕像[5-7]。后来激光清洗成为文物修复和保护的一个重要手段。激光除漆是当今激光清洗的一个重要应用方向,最早的激光除漆实验研究是1974年福克斯(J. A. Fox)用Q开关钕玻璃激光有效去除了树脂玻璃和金属基底上的油漆层[8]。

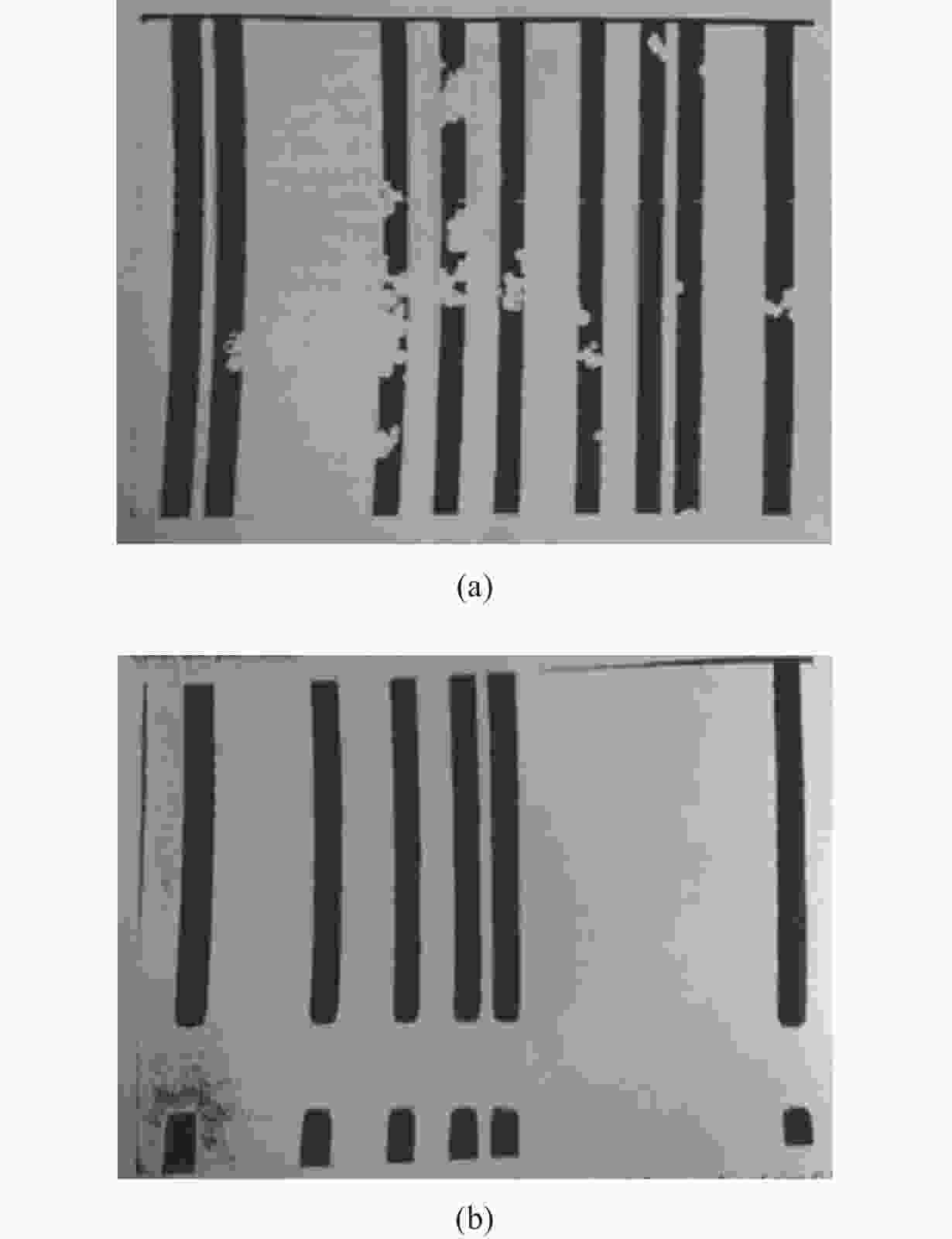

20世纪80年代,美国IBM公司研制出电子束投影刻蚀技术,制备掩模版时其表面不可避免地会沾上微粒污染物,导致出现次品,但传统的超声波清洗、机械清洗、化学清洗等技术等无法清除微粒污染物。1982年,IBM公司德国制造技术中心的扎普卡(W. Zapka)等人用聚焦激光照射掩模版,成功地将附着的污染物清洗掉,而掩模图案丝毫不会受到损伤[9]。图2(a)为一块污染后的硅掩模版,导线宽约1.8 μm,白色不规则形状代表污染微粒,线度为0.3~1.5 μm,图2(b)为激光清洗后的图片[10]。1987年7月2日,扎普卡在德国申请了第一个关于激光清洗方面的专利 [10]。

图 2 (a) 一个附着有 Al2O3球形污染微粒的硅掩模版; (b) KrF 激光清洗后的照片

Figure 2. (a) A silicon mask with Al2O3 spherical pollution particles atta-ched; (b) Photo after KrF laser cleaning

前苏联彼得洛夫(Yu.Petrov)研究小组在激光清洗线路板方面也独立开展了研究工作。1987年,他们率先发表了激光清洗表面微粒的论文,这是公认的第一篇激光清洗微粒方面的论文[11]。该论文的作者之一普罗霍洛夫(A.M. Prokhorov)是激光领域的先驱,于1964年因为激光方面的开创性工作和突出贡献,与汤斯、巴索夫共同获得了诺贝尔物理学奖。

作为一种新型高效的环保清洗技术,激光清洗的研究和应用吸引了越来越多的关注。此文对激光清洗技术原理、特点、发展等进行综述,对中国近年来的激光清洗的发展进行回顾。

-

激光清洗,通过光学聚焦整形系统把高亮度和方向性好的激光,照射物体待清洗样品,污染物吸收激光后,通过光剥离、汽化等过程,离开物体表面。可通过计算机对激光束的扫描过程进行控制,对清洗表面进行监测,实现激光清洗自动化控制。图3给出了激光清洗的装置示意和清洗原理图。

与其他清洗方法相比,激光清洗法具有以下诸多优点:(1) 环境污染少,(2) 安全,(3) 无机械接触,(4) 可精确定位,(5) 能实时控制和反馈,(6) 多种清洗对象,(7) 激光清洗效率高,(8) 长期运行成本低。

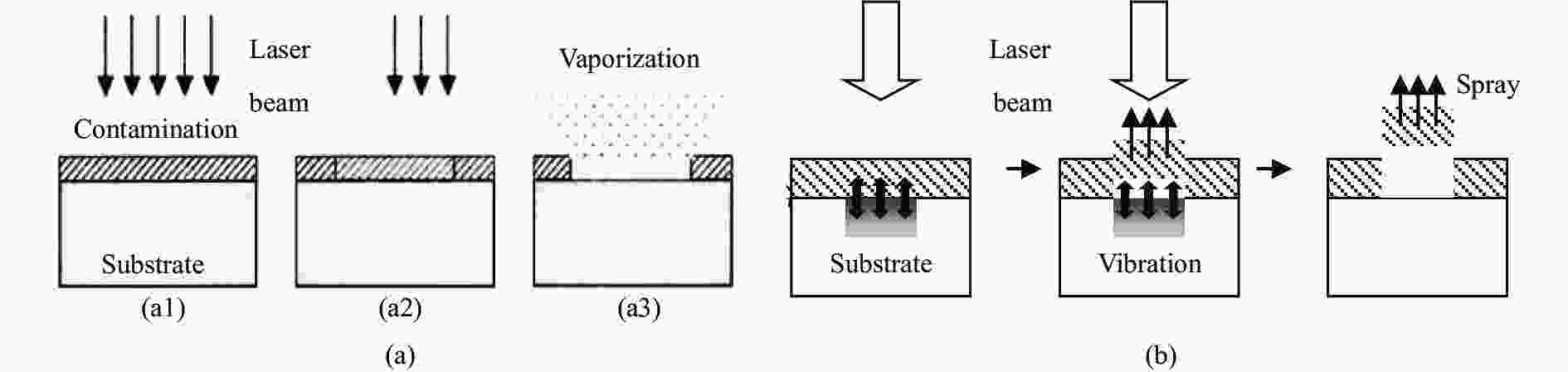

从是否使用辅助材料,激光清洗可以分为三种类型:干式激光清洗(Dry Laser Cleaning, DLC)、蒸汽式激光清洗(Steam Laser Cleaning, SLC)、湿式激光清洗( Wet Laser Cleaning, WLC)。湿式激光清洗法和蒸汽式激光清洗法,最常用的液体是水,使用方便,没有污染。前者将清洗对象浸泡在水中,后者则是喷洒气态物质使得在样品表面形成液膜,控制好液膜厚度。液体的功效是:保护清洗对象不至于因为温升过快而损伤;吸收激光能量形成过热液体或相爆炸,将污染物清洗掉。在实际操作中,湿式激光清洗和蒸汽式激光清洗中使用的液体量很难控制、清洗机理很难区分,所以一般倾向于不加区分,而统一称为湿式激光清洗法。图4为干式和湿式激光清洗示意图。

干式激光清洗设备简单,应用更加广泛;湿式激光清洗效率更高,但由于需要加入液体,对控制工艺有了更高的要求,还要防止液膜的侵蚀和锈蚀作用,这限制了其应用范围。

-

由于污染物的成分和结构很复杂,激光与之作用的机理也有所不同,科学家们提出了各种理论模型对此进行解释 [12-13]。

早期在激光干式清洗微粒的机理研究中,陆(Y.F. Lu)研究组指出激光清洗的机理包括光分解、烧蚀和表面振动[14-15]。卢克扬楚克(B.S. Luk‘yanchuk)、阿诺德(N. Arnold)研究组建立了一维热膨胀的干式激光清洗模型,考虑了近场光学增强和三维热膨胀效应[16-19]。格罗觉(D.Grojo)[20-21]研究了干式激光清洗过程中喷射粒子动力学,利用原位诊断方法研究了可能涉及“激光-粒子-表面”相互作用的各种烧蚀机制。其他科学家也对微粒的激光清洗理论机制进行了研究,如张(Zhang P)[22]理论分析了等离子体激波与附着球形粒子相互作用的动力学过程,考虑了激波载荷引起粒子接触半径的变化。吴东江[23]建立了一维热传导模型,利用有限元分析软件模拟硅片表面的温度随激光作用时间和能量密度的分布,量化了颗粒所受到的清洗力以及其与硅片表面之间的粘附力。林(Lim)提出了冲击波机制[24],因空气电离产生的等离子体冲击波使得污染物从基底剥离。

对于油漆、锈蚀的激光清洗机理和模型,有激光除漆中的激光汽化效应、热应力效应和激光等离子体效应、光化学分解、有限元模型模拟分析温度场[25-30];激光除锈中的烧蚀和热应力振动,以及薄膜屈曲效应和爆破效应[31-32]。

激光清洗机制研究中的理论模型,主要通过热传导方程,得到温度场分布[33],对于热振动机制,进一步计算其应力分布[30],并与粘附力进行比较。而粘附力主要来自范德华力,可由哈梅克模型给出[34]。对于冲击波的压强,可由色多夫模型计算得到[35]。

关于激光清洗机制,文献中提出的名词很多,概括起来主要有:(1)选择性汽化,污染物吸收激光后熔化或汽化;(2)光化学机制,污染物分子吸收激光能量,化学键发生振动、弯曲、甚至断裂,使得分子发生分解;(3)热膨胀机制,污染物和基底材料对激光的吸收能力有所差别,各自的物理属性(热导率、杨氏模量、热膨胀系数等)也不同,基底材料和污染物发生膨胀程度不同,膨胀到一定程度时,形成了脱离力;(4)热应力机制,材料吸热后会热胀冷缩而产生形变,形成的热弹性应力大于粘附力时,污染物将从基底剥离;(5)热弹性振动机制,污染物(基底)材料受热产生瞬时膨胀,对基底(污染物)施加压力,并产生了向材料内部传播的应力波,在材料的自由表面以拉伸波的形式反射,形成振荡;(6)逆韧致剥离或等离子体效应[12-13],激光使得清洗对象附近空气或污染物电离并强烈吸收激光能量,产生冲击波,使得污染物脱离基底;(7)光致压力,高度聚焦的激光对辐射表面产生压力,使得微小污染物(如微电子元件中亚微米颗粒)去除;(8)相爆炸机制,对于疏松多孔的氧化物膜层,激光的加热作用将使得压强增大,形成爆炸,带动污染层破碎并剥离。以上这些机制,有些是相似的,只是不同论文里的说法不同而已。将这些提及的机制和术语做一个大概的归纳,如图5所示。

概括起来,可以将以上机制归为两大类:(1) 烧蚀机制,包括选择性气化、蒸发、光化学机制等,(2) 剥离机制,包括热弹性振动、蒸汽压力、光致压力、相爆炸、冲击波等。前者产生了相变,污染物分解成新的物质或者变成了气态或液态;后者污染物维持原来的物态。如图6所示。烧蚀机制中,污染物瞬时达到很高的温度进而熔化或气化;如果激光提供的能量足以破坏表层物质的化学键,则是光分解机制。剥离机制中,污染物和基底材料吸收激光后,产生热弹性膨胀,进而产生脱离应力,则是热振动机制;如果激光使得污染物附近空气电离,则是等离子体冲击波机制;湿式激光清洗时,液体吸热升温形成过热液体或气泡破裂引起爆炸,则是相爆炸机制。

-

因为掩膜版中激光清洗的成功,科学家们掀起了对激光清洗电子印刷电路、电子元器件的研究热潮,研究了不同波长、不同脉冲宽度、不同能量密度、不同入射角等因素对清洗效果的影响。研究的基底大多是硅片,主要是因为半导体工业中硅片上的微粒去除最为迫切,其他的基底还有PI、PMMA、Ge、NiP、锂、石英玻璃等。研究的微粒和薄膜材料有PS、Cu、W、SiO2、Al2O3、橡胶、光刻胶等,形状有球形、扁平形以及无规则形状,微粒尺寸从几十纳米到几百微米[36-37]。

准分子激光、CO2激光被广泛用于干式清洗沉积在熔融石英或硅衬底上的微粒或吸附膜层[38-40],以及柔性电路板中的聚酰亚胺微粒[41],清洗率从12%到88%不等。俄罗斯科学家彼得洛夫(Y.N.Petrov)课题组首次报道了湿式激光清洗[42],将硅片浸泡在深度为0~5 mm的水中,在激光作用过程中会产生的声波有助于微粒清除[43-44]。美国的唐(A.C. Tam)[45-46]、阿伦(S.D.Allen)教授[47-49]等课题组也进行了大量湿式激光清洗微粒的研究,并不断改进实验参数和实验方法,以提高清洗效率和清洁度[50-54]。

进入21世纪后,研究更加注重细节,如激光参数、微粒的影响。从事研究的国家和科技人员也更多,既包括欧美国家的研究团队,也包括亚洲的新加坡和韩国学者 [55-58],中国学者[59]也加入了研究队伍。激光能量、入射角、污染微粒种类和粒径等参数对激光清洗效果的影响是重点研究方向[60-63],采用了多种检测方法来测量清洗效果,如椭偏仪、俄歇电子能谱[64],还尝试了在线监测[65]。

佩里(M.Peri)[66]的书中指出,在激光清洗技术中,短脉冲激光是微粒脱离基底材料的能量来源。在半导体工业中,随着纳米制造中特征尺寸的不断缩小和待去除表面上微粒数量的不断减少,微粒清洗越来越难,成品率仍然是微纳制造中的一个关键问题。常用的清洗技术包括机械刷洗、超声波清洗、离心喷雾清洗、气相清洗、流体喷射清洗和低温清洗,虽然可以去除大量的微/纳米尺度的粒子,但也存在三个主要问题:(1)材料损坏;(2)化学残留物造成的污染问题(例如,雾状缺陷);(3)难以精确清洗,而激光清洗则可以全部或少部分解决这些问题。

-

文物种类很多。石材是古建筑、雕塑等的重要原材料,石材的品种很多,有大理石、石灰岩、花岗石等;金属制品文物包括古钱币、工艺品、装饰品等,比如,建筑物上的铜屋顶、青铜器和青铜雕像、古钱币、金属纺织绣品;留存下来的木质文物易腐朽且雕刻凹槽中的污染物很难清洗;油画文物通常有一层涂层,用来保护画作,但是经过长时间的风化,表面的涂层都会受到损坏,在维护和修复时,需要去除表面破损涂层;羊皮纸、宣纸、丝绸等材料是古代人写字、作画的常用介质;此外还有化石、陶土、石膏、蜡雕等文物材料。

文物表面往往覆盖着土壤污染物、腐蚀产物、灰尘、有机污渍和结壳,改变了其化学成分和美学外观。对受到污染的文物需要进行清洗,以避免进一步腐蚀污染,同时恢复文物本来面貌。文物是不可再生的稀有物品,清洗时需要非常谨慎,不能有任何破坏。传统的文物清洗方法主要有化学法、机械法,均会在清洗过程中对文物本体造成一定程度的损伤。自1974年起,阿斯姆斯(Asmus)等人[4-7]陆续对多种文物古迹进行了激光清洗研究,开启了激光清洗在文物保护和处理方面的应用方向。进入90年代后,文物的激光清洗研究迅速引起了广泛关注。进入21世纪,对文物的激光清洗研究更是得到了蓬勃发展,从最初的清洗是否有效、与传统清洗技术(机械清洗、化学清洗)的比较,到激光参数(波长、能量、脉冲数等)对清洗效果的影响、采用光谱等测试手段评判清洗效果、清洗机理和副作用(激光清洗石材和纸张后的变色等问题)的成因分析,科学家们都做了大量的研究,得到了有用的结论。除了实验室研究外,还在实际文物清洗中开展了行之有效的工作。图7是赫尔墨斯雕塑雕像清洗前后对比照片,左为原始污染后的雕像,右为激光清洗后的照片,右下角为清洗前后耳朵部位的细节[67]。表1列举了常见文物的激光清洗研究情况。

表 1 激光清洗文物举例

Table 1. Examples of laser cleaning cultural relics

Base material Category Specific research content Literature

(serial number)Stone (marble, limestone, granite) Ancient architecture

statueEffects of surface roughness, porosity and water content of mortar [75]

Influence of laser parameters and stone cladding color on cleaning efficiency [76-78]

Discoloration problem [79-80][68-80] Metalwork Ancient coins, handicrafts, ornaments, etc Copper roof of Wilanow Palace in Warsaw, Poland[81], fragments of original historic sites in St. Petersburg [82], copper alloy plates on rudders of ancient shipwrecks [83], bronze bells [84], the Paradise Gate of gilded bronze artifacts from the Renaissance in Florence [85]

Samuel Morse Statue [86]

Coins of the late British Saxon and Norman periods [87], Roman Imperial copper based quaternary alloys [88], Roman and Byzantine coins, and ancient Alexandrian coins [89-91]

Fabric embroidered with gold, silver, or copper wire [92-94].[81-94] Wooden relics Statue

ornamentThe effect of laser wavelength [95-97]

The influence of energy density [98]

Carve the notched area [99][95-99] Oil painting Influence of different laser parameters (wavelength, pulse width, repetition rate and energy density) on oil painting surface [100-101]

Efficiency and canvas integrity compared with traditional cleaning techniques [102]

Study on the mechanism of laser cleaning oil painting [103-104][100-104] Cellulose Parchment, rice paper, silk, linen and cotton products, etc Laser cleaning of various products [105-110]. "Yellowing" and other discoloration phenomena and solutions [111-113] [105-113] Other Fossil, glass A sample of fossil mammalian bones [114-115]. Cultural relics such as clay, plaster and wax carving were cleaned [116] [114-116] 在文物清洗过程中,要避免文物损伤,所以需要合适的激光波长和激光能量(单位面积的激光能量或峰值功率),既要达到清洗阈值,将污染物去除掉,又不能达到损伤阈值,以免损伤文物。文物清洗还有一个重要特点,就是特别注重监测,这跟文物的不可再生性有关。在激光清洗前后以及清洗过程中,采用了多种测量方法,以监测控制和表征激光清洗过程和清洗效果[117-120]。

-

工农业生产和仪器设备维护中,脱漆除锈是最常见的工序之一。去除金属上油漆和腐蚀最常用的方法有喷丸和化学清洗法,这两种方法效率高、技术成熟,但是污染环境、有损操作者健康。20世纪,激光脱漆[121-122]和除锈[123]的研究开始起步。与激光清洗文物、半导体相比,其研究虽然相对较晚,但是进入21世纪后得到了更广泛的关注,尤其是近10年来,进入了研究高潮。其成本低、环保、效果好,可以替代常规清洗方法[124],已在工业生产中逐步有了应用。

研究者们采用多种激光(主要有CO2激光、Nd:YAG激光、Yb光纤激光)进行了脱漆除锈研究,通过显微镜观测、化学成分测量等多种手段,分析激光参数(波长、脉宽、能量密度)、油漆参数(种类成分、厚度、颜色等)对脱漆除锈效果的影响[125-126],提出激光脱漆除锈的物理机制。

-

船舶、飞机、桥梁等大型设备都需要定期重新涂装,这就离不开脱漆(或称为除漆),以去除老化破损的油漆,不损伤基底,方便后续重新涂装。激光除漆法对基底无损伤、耗电量低、可自动操控、对环境污染少。

(1) 金属表面涂层清洗

钢铁是工业中应用最多的材料之一,比如轮船甲板在涂装前需要进行除漆,这是一个具有重大经济效益的产业。沙姆苏基沃哈(M. Shamsujjoha)[127]、刘(Y. Liu)[128]用激光清洗船用钢板上的环氧基涂料,去除效果非常显著。重新涂装后,油漆与钢板的附着力与喷丸清洗的相当,甚至更好。

铝合金因其强度高、耐腐蚀能力强,在工业中使用越来越多,汽车、飞机等交通工具以及工业设备上所用铝合金的除漆[129-132]、激光清洗参数对工件表面粗糙度的影响[133]、激光除漆后铝合金基底材料的性能(疲劳性能、硬度、杨氏模量等)[134-135]等研究表明,清洗效果好,且材料表面性能有所提高,如图8所示[136]。其他金属如铜上油漆的激光清洗,也证明是可行的[137]。甚至于其他种类的涂层也可以用激光清洗,比如,TiN涂层对提高航空发动机在沙尘环境下的耐磨性和抗冲击性有积极作用,通过激光可以清洗掉老化的涂层[138],清洗效果明显。

激光除漆中,由于油漆熔点较低,有可能产生火焰,一方面部分地阻挡了激光束,减弱其清洗效率,另外一方面会污染设备,甚至有火灾隐患。匡[139]研究了一种能有效抑制燃烧火焰、等离子体和火花的激光脱漆技术,可有效去除油漆,并能有效抑制火焰和火花。

(2) 复合材料表面

复合材料质量强度大,应用越来越广泛,比如,在飞机中,碳纤维增强聚合物(CFRP)逐渐取代铝合金。在使用中,粘合剂可以用来最大限度地提高CFRP的材料性能,但是碳纤维表面残留的脱模剂会引起粘附问题。用激光清洗CFRP上的油漆,通过研究激光参数对清洗过程的影响以及对碳纤维表面的影响,发现激光清洗后有利于提高粘接样品的拉伸性能和粘结性能,试件强度比机械磨削清洗的强度提高了很多[140-141]。

-

建筑物、桥梁、很多仪器设备,都使用了金属材料。在生产过程中,由于金属材料放置在仓库中,表面容易产生一层氧化层(腐蚀);在使用一段时间后,也会产生腐蚀现象。1998年,拉法格(P.E Lafargue)[142]使用准分子激光器和 Nd:YAG 倍频和四倍频激光器,去除了约90%的表面污染物和75%的铁粉。此后,更多的研究都表明了激光去除金属表面腐蚀层的可行性和有效性[143-145],且对工作场所的要求比传统喷丸和化学法要低。

由于腐蚀产物和基底材料的结合比油漆与基底的结合更为紧密,在激光除锈时,往往需要更大的能量或峰值功率密度;同时,由于基底材料上各处腐蚀层不均匀,在激光除锈时对于腐蚀轻微处基底吸收激光能量更多,容易导致基底损伤。因此,采用激光清洗金属表面腐蚀后,金属基底材料的性能是否有所改变,是工业上非常关心的。研究表明,激光清洗前后的基底的表面粗糙度几乎没有变化,性能几乎没有影响[146-147],甚至更好,比如,钢表面具有更好的自清洁性能[148],铝合金表面的粗糙度、组织、元素含量、显微硬度、残余应力和耐腐蚀性能有所增强,光洁度和强度均可有效提高[149]。研究还表明,激光除锈后,金属的耐腐蚀性还有所提高,这是因为激光除锈过程中,新形成了保护作用较强的钝化层,提高了材料的抗腐蚀性[149-157]。不过,激光除锈需要保持合适的参数,当激光强度和脉冲数超过了某个值,会出现变色现象,这是空气中的氧气与不锈钢之间的热化学反应导致的[158]。

以上研究表明,只要参数合适,激光清洗对材料性能基本没有负面影响,反之还可能提高某方面的性能,如耐腐蚀性。

-

激光清洗还被用在其他材料上。汤姆孙散射实验中,光学窗经常受到污染,成原(K.Narihara)[159]用激光清洗汤姆逊散射窗,获得了满意的清洗效果。陆永枫团队尝试了很多材料的激光清洗,如玻璃和石英表面上的指纹[160]、 磁头表面吸附颗粒[161]。工业上常用的陶瓷砂轮,在经过一段时间的磨削工序后,表面会黏上金属屑,使得磨削效率下降,通过激光清洗可以提高切削效率[162]。德国于1997年启动了一个研究项目“彩色玻璃窗的激光清洗”[163],研究了激光在彩色玻璃修复中的可行性,如图9所示。

图 9 激光清洗涂有杂聚硅氧烷的玻璃后的显微图,左:以0.5 J/cm2、10 Hz、100次脉冲去除涂层后的自然裂纹形态无损伤;右侧:可见残留涂层[155]

Figure 9. Light microscopy; corroded glass, coated with aheteropolysiloxane; on the left side: the coating was removed with 0.5 J/cm2, 10 Hz, 100 pulses, no damage on the natural crack pattern of the gel layer; on the right side: residual coating visible[155]

激光清洗的范围不断扩大,已用于海面泄露石油 [164]、油污零件和板材[165]、纸张[166-167]、发动机积碳[168-169]、蛋壳[170]、皮革[171]、丝织物[172]、城市涂鸦[173]、光学薄膜[174]、磁流变光学加工[175]、玻璃或金属镜面[176-180]、同步辐射元件[181-183]、探针电极[184-187]、雷达组件[188]、石墨烯[189]、牙齿[190]等。

由以上介绍可知,激光清洗的效果已经得到认可,在微电子领域、文物保护领域中的研究相对较多,同时,尝试了多种清洗对象,基底材料有金属、光学玻璃、复合材料等,污染物有颗粒、油漆、氧化层等。所采用的激光器除了准分子、CO2、Nd:YAG激光器外,光纤激光器的使用也增多了。

-

激光清洗前后和清洗过程中,可以通过各种监控手段判断清洗效果和清洗进程。文物的激光清洗监控开展得最早,此后其他清洗也逐步引入。监控包括监测和控制。监测的目的是确定清洗进程和判断清洗效果,而控制则是根据监测结果控制清洗参数和清洗过程。

-

监测激光清洗效果和激光清洗效率的常用监测技术有成像技术、光谱技术等。在监测时往往离不开图像处理技术,以对图像和光谱进行识别、去噪、分析。

成像技术可以通过直接观测(通过眼睛成像)、照相、光学显微镜、电子显微镜等。如希德尔(H. Siedel)[191]对19世纪留存下来的因风化、老化和油漆而被污染的砂岩文物,通过光学和扫描电子显微镜以及颜色测量,比较了激光清洗和其他清洗方法。表2总结了常用成像技术。

表 2 常用成像监测技术

Table 2. Commonly used imaging monitoring techniques

Means of measurement Cleaning object Measurement result (parameter) Literature

(serial number)Optical microscope and scanning electron microscope Copper and copper oxide on circuit boards The thickness of the covering layer is reduced from 15-25 nm to ≤ 10 nm [17] Atomic force microscopy (AFM), optical and scanning electron microscopy Acrylic ester on Si sheet The differences in effectiveness and reliability of excimer laser and Si-masters reactive ion cleaning are discussed [19] Optical reflection, photoacoustic beam deflection probe laser and flash photography techniques Pollution particles on the NiP disk substrate The mechanism of wet laser cleaning of contaminated particles on the nip hard disk substrate was studied [27] Optical microscope Metal surface coating material Ablative with TEA CO2 laser pulse [97] Optical microscope Stainless steel surface γ-Fe2O3 and Fe3O4 formed on the surface of stainless steel are found [125] Scanning electron microscope The rust of the ship The corrosion resistance of the laser cleaned surface is about 5 times that of the corroded surface [129] Optical microscope The oxide layer on Si(100) surface Complete pollutant elimination is achieved [167] Optical microscope The oxide layer on Si(100) surface Complete contaminant elimination is achieved without any damage to the surface [168] Plume imaging technology Inlaid stone carvings It is an inexpensive tool for real-time monitoring of laser ablation and determining safe surface cleaning interventions [174] Imaging analysis Carbon steel Q235 Improving cleaning efficiency, qualified rate of 92.5% [177] Scanning electron microscope Paint The infrared absorption spectrum of the clean surface has two additional peaks [192] Scanning electron microscope Q345 (Gr·B) steel surface paint The surface is relatively flat, the content of Fe and C elements reaches 89% and 9% respectively, and the hardness is improved [193] 光谱技术是另外一种广泛使用的检测技术,包括吸收光谱、反射光谱、傅里叶红外光谱、激光诱导等离子谱。通过光谱技术可以知道清洗对象在清洗前后的成分以及清洗过程中的成分变化。比如,拉茨普瑞特(R.Larciprete)[192,194]在研究Si(100)表面的氧化物层(SiOx (x<2))层激光清洗时,通过光学显微镜观察形态,并采用俄歇电子能谱(AES)、低能电子衍射能谱(LEED)、X射线光电子能谱(XPS)等方法研究了激光能量密度和总光子数对清洗效果的影响。表3总结了常用的光谱技术。

表 3 常用光谱监测技术

Table 3. Common spectral monitoring techniques

Means of measuremen Cleaning object Measurement result (parameter) Literature

(serial number)X-ray electron spectroscopy Copper and copper oxide on circuit boards The thickness of the covering layer is reduced from 15-25 nm to ≤ 10 nm [17] Laser induced breakdown spectrum Ancient Pentelic marble covered with a black crust Select the best laser parameters for effective cleaning [46] X-ray fluorescence analyzer Historical site surface pollutants and natural sediments X-ray fluorescence analyzer can be used to monitor the quality of laser cleaning of historic sites [58] X-ray powder diffraction, pyrolytic-gas chromatography-mass spectrometry, portable X-ray fluorescence spectroscopy City statue Degradation products affecting its surface and organic coatings for protection were analyzed [62] Laser induced fluorescence, laser induced breakdown spectrum, Fourier transform Raman spectrum and infrared spectrum Coloured wooden ceiling The influence of laser wavelength is studied [72] Laser induced fluorescence spectroscopy, laser induced plasma spectroscopy Fine biocomposites such as 15th-and 16th-century parchment manuscripts and 19th-century printing paper The feasibility of the two technologies in the field of non-destructive on-line monitoring is studied [81] Energy dispersive X-ray analysis Metal surface coating material Ablative with TEA CO2 laser pulse [97] Energy dispersive X-ray analysis Two Malaysian car coatings The balance of carbon and oxygen components in the cleaning process helps to reduce the coating [105] Auger electron spectroscopy Stainless steel surface γ-Fe2O3 and Fe3O4 formed on the surface of stainless steel are found [125] Glow Discharge Emission Spectra (GDOES) and X-ray Photoelectron Spectroscopy (XPS) AA7024-T4 aluminum alloy The change of material properties is related to the change of surface oxide state [127] Raman spectral analysis Marine metal The relationship between laser power output and Raman spectrum is established [128] X-ray photoelectron spectroscopy and scanning electron microscopy The rust of the ship The corrosion resistance of the laser cleaned surface is about 5 times that of the corroded surface [129] Auger electron spectroscopy (AES), low energy electron diffraction spectroscopy (LEED), X-ray photoelectron spectroscopy (XPS) The oxide layer on Si(100) surface Complete pollutant elimination is achieved [167] Auger electron spectroscopy (AES) The oxide layer on Si(100) surface Complete contaminant elimination is achieved without any damage to the surface [168] Laser induced breakdown spectrum Inlaid stone carvings It is an inexpensive tool for real-time monitoring of laser ablation and determining safe surface cleaning interventions [174] Fiber Optic Reflection Spectroscopy (FORS) and Visible and Near Infrared (VNIR) Hyperspectral Imaging (HSI) Limestone surface Assess protection status and determine more appropriate cleaning recovery levels [175] Fourier transform infrared spectroscopy, X-ray photoelectron spectroscopy Paint The infrared absorption spectrum of the clean surface has two additional peaks [192] Electron backscatter diffraction Q345 (Gr·B) steel surface paint After cleaning, the surface is relatively flat, the content of Fe and C elements reaches 89% and 9% respectively, and the hardness is improved. [193] 还有通过电磁顺磁共振技术、硬度计、粒度计、光学轮廓扫描仪测量实时反射率等手段,测量得到表面信息[195],如表4所示。

监测的目的是为了合理选择和控制激光参数,以控制激光清洗进程,保证良好的清洗效果。监测可以分为离线监测和在线监测。前者是激光清洗后,关闭激光,对样品进行测量,判断污染物是否被清洗干净,样品是否有损伤;后者是在清洗过程中进行监测,在激光辐照样品时,监测相关参数,判断清洗效果,并判定激光参数是否合适。在线实时监测可以结合控制系统,一边监测,一边控制激光器进行清洗。在线测量要求更高,难度更大,根据在线测量结果,通过计算机进行数据处理、分析、判断,进而控制激光清洗过程,还刚刚起步。未来,基于在线监测的激光清洗智能控制将是研究的主流方向。

表 4 表面信息的监测技术

Table 4. Surface information monitoring technology

Means of measurement Cleaning object Measurement result (parameter) Literature

(serial number)Real-time reflectance measurement Oxide on Ge crystal sheet The energy density cleaning threshold and damage threshold of 193 nm cleaning c-Ge sheet were determined [16] Acoustic monitoring Contaminated limestone sculpture Acoustic monitoring can judge the cleaning effect in real time [44] Surface roughness and surface morphology Polyurethane coating for hull plate surface Laser cleaning has a remarkable effect on the removal of polyurethane paint from ship shell factory [104] Surface bonding strength Resin residue on the surface of CFRP materials The bonding strength is 1.6 times that of the surface without laser cleaning [116] Continuous measurement of surface photocurrent Pure tungsten photocathode Real-time monitoring of cleaning effect [159] Surface roughness Metal A two-stage process parameter adjustment and surface roughness estimation algorithm based on image analysis was proposed [176] -

基于声学、色度学和智能技术的激光清洗控制技术已经发展起来,不仅可以实现激光清洗,而且可以实现过程的自动控制。早在20世纪90年代,就有一些研究人员指出激光在线监测和自动控制的可能性。马拉维拉基(P.V. Maravelaki)[70]在激光清洗古代Pentelic大理石时,指出LIBS可以作为一种自主的在线诊断技术,为完成清洗提供必要信息。布里格(V.B Bregar)[196-197]通过测量光声波在线观察清洗过程的进展,在连续波的振幅和传播速度(接近声速)都达到一定值时,清洗过程结束。希尔登哈根(J. Hildenhagen)[198]使用光电二极管来检测来自艺术品表面辐照区域的散射光,激光彻底去除污染物后,散射光振幅甚至脉冲带宽有明显的改变,相应的信号可用于闭环控制或在线监测。柯和智(A.Khedr)[199]激光清洗大理石基底时,采用羽流成像技术实时监测激光烧蚀,以控制文物的激光清洗过程。库奇(C. Cucci)[200]对意大利巴里市著名的斯沃堡(Castello Svevo)入口处深黑色石灰岩进行激光清洗时,采用光纤反射光谱(FORS)和可见光及近红外(VNIR)高光谱成像(HSI)对清洗过程进行评估和控制。塞内斯(G.S. Senesi)[120]在激光清洗意大利巴里的古石灰岩门柱的过程中,采用LIBS技术监测、控制和表征。

在线监测并实现激光清洗的智能控制,离不开计算机技术。近年来,这方面的工作逐渐展开。李(J. Li)[201]对Q235碳钢的激光清洗,采用了一种基于成像分析的智能技术,包括离线和在线计算模型。刘(H. Liu)[202]在激光清洗前,对样品采集图像,通过计算得到分类特征,使用支持向量机(SVM)预测清洗效果。激光清洗后,对清洗后的图像计算多个图像特征,以控制激光清洗过程。

-

国内的研究基本上起始于21世纪。南开大学在《清洗世界》杂志发表了系列文章,介绍激光清洗[203-206]。半导体材料及其他材料上的微粒的激光清洗研究开展相对较早,如陈浩[207]从理论和实验上对激光湿式清洗印刷线路板进行了初步研究,李绪平等[208]对石英基片的微粒进行激光清洗,叶亚云[209]对镀金K9玻璃进行激光清洗。

对文物的激光清洗也做了尝试。张晓彤[210]针对一件鎏金青铜造像进行激光清洗后,造像面部及周身线条轮廓清晰,散发鎏金光泽,体现了原有工艺价值。赵莹[211]对纸本书画(宣纸)上产生的霉菌进行了激光清洗。

在激光脱漆除锈方面,陈菊芳等[212]采用CO2激光去除铝板表面的油漆层,研究了激光功率密度、扫描速度及扫描道间搭接量与油漆去除效果之间的关系。杜鹏[136]使用Nd:YAG声光调Q激光器,较为系统地研究了准连续激光除漆,并通过简化的一维热应力模型计算出激光照射后基底的表面温升、清洗阈值和损伤阈值。施曙东[193]对钢基底表面漆层样品进行了激光清洗实验和工作机理研究。章恒[213]对FV520B铝合金基底的表面漆层进行了激光除漆实验和机理研究。路磊[214]采用双波长激光(1064 nm和532 nm)进行了大面积钢板除锈和铜板除锈激光清洗实验研究。李(X.Li)[215]研究了纳秒脉冲激光去除Q345 (Gr·B)钢表面油漆的情况以及清洗后表面的组织和硬度。

中国学者也研究了其他方面的激光清洗,如激光清洗模具[216]、蒸汽发生器传热管[217]、印刷机械中的丝网部件[218]、钴铯污染层[219]、镜片上的油脂[220]和指纹[221]、航空液压管路系统中的钛合金[222]、电极[223]、牙科中的牙齿正畸托槽[224]、城市涂鸦[225]、聚氨酯涂料船壳板表面、采矿零件、碳纤维表面树脂、铝合金氧化膜[226]、CFRP表面[227]和微生物污垢表面[228]等。

目前南开大学、中国科学院半导体研究所、哈尔滨工业大学等众多单位都在开展激光清洗研究,表5给出了部分单位的研究动态,表6列出了常用激光器和清洗污染物。

表 5 国内部分单位对激光清洗的研究

Table 5. Research on laser cleaning in some domestic units

Organization Laser Wavelength/

nmCleaning object Base Pollutant Literature

(serial number)Nankai University Nd:YAG laser 150 Homemade sample Aluminium alloy Paint [229] Harbin Institute of Technology Nanosecond fiber pulse laser 30-100 Homemade sample Titanium alloy Oxide layer [230] Huazhong University of Science and Technology Pulse laser with maximum Power of 100 W (YDFLP-100-LM1) 100 Homemade sample Aluminium alloy Oxide layer [231] Jiangsu University IPG-HP-100 laser 100 Homemade sample Steel Oxide [232] Jinan University All solid state fiber coupled output laser 50 Aluminium alloy tyre mould Aluminium alloy Sulfide [233] Hunan Engineering and Technology Research Center of Aircraft Maintenance All-solid state quasi-continuous laser (IS-0604QCW) 100 Homemade sample Aluminium alloy Paint layer [234] 表 6 主要激光器和污染物

Table 6. Mainly used lasers and contaminants

Laser Type Wavelength/nm Cleaning contaminant Literature

(serial number)Excimer laser ArF, KrF 193, 248 Granules and paints [235] Nd:YAG laser Nd:YAG 352, 532, 1 064 Metal contaminant [236] Er:YAG laser Er:YAG 2 940 Pollutant cleaning of cultural relics [89] Fiber laser Fiber laser 1 064 Paint, rust [237] Gas laser CO2 laser 1 0.6 Paint on non-metallic materials [238] -

激光清洗是随着激光技术的发展而诞生的,随着对环境保护的要求越来越高,激光清洗技术的研究和应用也越来越得到关注。20世纪60年代提出激光清洗概念,70年代用于文物清洗,80年代用于半导体材料清洗,并发展了湿式激光清洗技术,90年代在文物、集成电路方面的研究取得突破。进入21世纪,作为一种新型高效的环保清洗技术,干式激光清洗、湿式(含蒸汽式)激光清洗、监控技术得到进一步发展,在电子元器件、文物和脱漆除锈等方面的研究和应用更为广泛。目前激光脱漆除锈、实时监测与自动控制,已成为新的研究热点。

目前激光清洗已经被应用在半导体加工、飞机蒙皮、文物保护等领域。基于环保和效率要求,近年来我国科研人员也对激光清洗表现出极大的热情,在激光脱漆除锈、模具清洗的研究和应用已经全面铺开,在激光清洗机理和应用实践等多个方面开展了研究并取得成效。科技部也设立了多个攻关项目,出版了若干专著包括国家重点出版规划图书[1]。激光清洗仍然面临许多挑战:(1) 模拟效果有待解决。对于复杂成分的污染物,在理论模型计算中,数据还不够完整,一些物理参数也会随着温度的变化而变化,这将导致很难定量准确地获取激光清洗过程中的清洗阈值和损伤阈值。(2) 实时清洗效果评估和智能化控制有待加强。激光清洗的实时监测与效果判断,并结合图像识别处理可以实现对清洗的区域实时清洗评估。同时,可以与机器人联动使用,实现自动化,提高清洗效率。(3) 混合清洗应用方面。由于污染物和基底种类较多,表现出不同的物化特性。其他清洗方式(如喷丸法、化学法)市场占有量巨大,面对这种客观实际情况,可以将激光与其他技术相结合,实现复合清洗,以降低成本,提高效率。

Review of laser cleaning technology (invited)

-

摘要: 激光清洗是通过把高亮度和方向性好的激光照射到物体待清洗的部位,使激光器发射的光束被污染层和/或基底吸收,通过光剥离、汽化等过程,克服污染物和基底之间的粘附力,使污染物离开物体表面,达到清洗目的,且不损伤物体本身的物理清洗技术。20世纪80年代以后,激光清洗技术得到了越来越多的关注。40年来,激光清洗作为一种新型高效的环保清洗技术,得到了飞速发展,在电子元器件清洗、文物保护和脱漆除锈等领域得到研究并获得了应用。2010年以后,对激光清洗研究进一步深入,在激光清洗的检测和智能控制方面取得较大成果,并且在激光清洗机理方面也取得了进展。中国科学家在这个过程中也做出了贡献。介绍了激光清洗原理、特点、源起,对40余年的激光清洗发展做了综述,并介绍了国内近年来激光清洗的研究动态。Abstract: Laser with the high brightness and good direction is irradiated to the object to be cleaned. After laser beam is absorbed by the pollution layer and/or substrate, with such processes as light stripping, vaporization, the adhesion force between pollutants and substrate is overcome so that pollutants leave the surface of the object, to achieve the purpose of cleaning, while causing no damage of the object itself. After the 1980s, laser cleaning technology has received more and more attentions. In the past 40 years, as a new efficient environmental cleaning technology, laser cleaning technology has developed rapidly and has been used in electronic components cleaning, cultural relics maintenance, paint and rust removal and other fields. Since 2010, further research on laser cleaning has been carried out, and great achievements have been made in the detection and intelligent control of laser cleaning. Breakthroughs have been made in the mechanism of laser cleaning. Chinese scientists have also made great contributions. The paper summarizes the principle, characteristics, origin and development of laser cleaning technology in the past 40 years, and introduces the development of laser cleaning in China in recent years.

-

Key words:

- laser cleaning /

- contaminant /

- light tripping /

- gasification

-

图 9 激光清洗涂有杂聚硅氧烷的玻璃后的显微图,左:以0.5 J/cm2、10 Hz、100次脉冲去除涂层后的自然裂纹形态无损伤;右侧:可见残留涂层[155]

Figure 9. Light microscopy; corroded glass, coated with aheteropolysiloxane; on the left side: the coating was removed with 0.5 J/cm2, 10 Hz, 100 pulses, no damage on the natural crack pattern of the gel layer; on the right side: residual coating visible[155]

表 1 激光清洗文物举例

Table 1. Examples of laser cleaning cultural relics

Base material Category Specific research content Literature

(serial number)Stone (marble, limestone, granite) Ancient architecture

statueEffects of surface roughness, porosity and water content of mortar [75]

Influence of laser parameters and stone cladding color on cleaning efficiency [76-78]

Discoloration problem [79-80][68-80] Metalwork Ancient coins, handicrafts, ornaments, etc Copper roof of Wilanow Palace in Warsaw, Poland[81], fragments of original historic sites in St. Petersburg [82], copper alloy plates on rudders of ancient shipwrecks [83], bronze bells [84], the Paradise Gate of gilded bronze artifacts from the Renaissance in Florence [85]

Samuel Morse Statue [86]

Coins of the late British Saxon and Norman periods [87], Roman Imperial copper based quaternary alloys [88], Roman and Byzantine coins, and ancient Alexandrian coins [89-91]

Fabric embroidered with gold, silver, or copper wire [92-94].[81-94] Wooden relics Statue

ornamentThe effect of laser wavelength [95-97]

The influence of energy density [98]

Carve the notched area [99][95-99] Oil painting Influence of different laser parameters (wavelength, pulse width, repetition rate and energy density) on oil painting surface [100-101]

Efficiency and canvas integrity compared with traditional cleaning techniques [102]

Study on the mechanism of laser cleaning oil painting [103-104][100-104] Cellulose Parchment, rice paper, silk, linen and cotton products, etc Laser cleaning of various products [105-110]. "Yellowing" and other discoloration phenomena and solutions [111-113] [105-113] Other Fossil, glass A sample of fossil mammalian bones [114-115]. Cultural relics such as clay, plaster and wax carving were cleaned [116] [114-116] 表 2 常用成像监测技术

Table 2. Commonly used imaging monitoring techniques

Means of measurement Cleaning object Measurement result (parameter) Literature

(serial number)Optical microscope and scanning electron microscope Copper and copper oxide on circuit boards The thickness of the covering layer is reduced from 15-25 nm to ≤ 10 nm [17] Atomic force microscopy (AFM), optical and scanning electron microscopy Acrylic ester on Si sheet The differences in effectiveness and reliability of excimer laser and Si-masters reactive ion cleaning are discussed [19] Optical reflection, photoacoustic beam deflection probe laser and flash photography techniques Pollution particles on the NiP disk substrate The mechanism of wet laser cleaning of contaminated particles on the nip hard disk substrate was studied [27] Optical microscope Metal surface coating material Ablative with TEA CO2 laser pulse [97] Optical microscope Stainless steel surface γ-Fe2O3 and Fe3O4 formed on the surface of stainless steel are found [125] Scanning electron microscope The rust of the ship The corrosion resistance of the laser cleaned surface is about 5 times that of the corroded surface [129] Optical microscope The oxide layer on Si(100) surface Complete pollutant elimination is achieved [167] Optical microscope The oxide layer on Si(100) surface Complete contaminant elimination is achieved without any damage to the surface [168] Plume imaging technology Inlaid stone carvings It is an inexpensive tool for real-time monitoring of laser ablation and determining safe surface cleaning interventions [174] Imaging analysis Carbon steel Q235 Improving cleaning efficiency, qualified rate of 92.5% [177] Scanning electron microscope Paint The infrared absorption spectrum of the clean surface has two additional peaks [192] Scanning electron microscope Q345 (Gr·B) steel surface paint The surface is relatively flat, the content of Fe and C elements reaches 89% and 9% respectively, and the hardness is improved [193] 表 3 常用光谱监测技术

Table 3. Common spectral monitoring techniques

Means of measuremen Cleaning object Measurement result (parameter) Literature

(serial number)X-ray electron spectroscopy Copper and copper oxide on circuit boards The thickness of the covering layer is reduced from 15-25 nm to ≤ 10 nm [17] Laser induced breakdown spectrum Ancient Pentelic marble covered with a black crust Select the best laser parameters for effective cleaning [46] X-ray fluorescence analyzer Historical site surface pollutants and natural sediments X-ray fluorescence analyzer can be used to monitor the quality of laser cleaning of historic sites [58] X-ray powder diffraction, pyrolytic-gas chromatography-mass spectrometry, portable X-ray fluorescence spectroscopy City statue Degradation products affecting its surface and organic coatings for protection were analyzed [62] Laser induced fluorescence, laser induced breakdown spectrum, Fourier transform Raman spectrum and infrared spectrum Coloured wooden ceiling The influence of laser wavelength is studied [72] Laser induced fluorescence spectroscopy, laser induced plasma spectroscopy Fine biocomposites such as 15th-and 16th-century parchment manuscripts and 19th-century printing paper The feasibility of the two technologies in the field of non-destructive on-line monitoring is studied [81] Energy dispersive X-ray analysis Metal surface coating material Ablative with TEA CO2 laser pulse [97] Energy dispersive X-ray analysis Two Malaysian car coatings The balance of carbon and oxygen components in the cleaning process helps to reduce the coating [105] Auger electron spectroscopy Stainless steel surface γ-Fe2O3 and Fe3O4 formed on the surface of stainless steel are found [125] Glow Discharge Emission Spectra (GDOES) and X-ray Photoelectron Spectroscopy (XPS) AA7024-T4 aluminum alloy The change of material properties is related to the change of surface oxide state [127] Raman spectral analysis Marine metal The relationship between laser power output and Raman spectrum is established [128] X-ray photoelectron spectroscopy and scanning electron microscopy The rust of the ship The corrosion resistance of the laser cleaned surface is about 5 times that of the corroded surface [129] Auger electron spectroscopy (AES), low energy electron diffraction spectroscopy (LEED), X-ray photoelectron spectroscopy (XPS) The oxide layer on Si(100) surface Complete pollutant elimination is achieved [167] Auger electron spectroscopy (AES) The oxide layer on Si(100) surface Complete contaminant elimination is achieved without any damage to the surface [168] Laser induced breakdown spectrum Inlaid stone carvings It is an inexpensive tool for real-time monitoring of laser ablation and determining safe surface cleaning interventions [174] Fiber Optic Reflection Spectroscopy (FORS) and Visible and Near Infrared (VNIR) Hyperspectral Imaging (HSI) Limestone surface Assess protection status and determine more appropriate cleaning recovery levels [175] Fourier transform infrared spectroscopy, X-ray photoelectron spectroscopy Paint The infrared absorption spectrum of the clean surface has two additional peaks [192] Electron backscatter diffraction Q345 (Gr·B) steel surface paint After cleaning, the surface is relatively flat, the content of Fe and C elements reaches 89% and 9% respectively, and the hardness is improved. [193] 表 4 表面信息的监测技术

Table 4. Surface information monitoring technology

Means of measurement Cleaning object Measurement result (parameter) Literature

(serial number)Real-time reflectance measurement Oxide on Ge crystal sheet The energy density cleaning threshold and damage threshold of 193 nm cleaning c-Ge sheet were determined [16] Acoustic monitoring Contaminated limestone sculpture Acoustic monitoring can judge the cleaning effect in real time [44] Surface roughness and surface morphology Polyurethane coating for hull plate surface Laser cleaning has a remarkable effect on the removal of polyurethane paint from ship shell factory [104] Surface bonding strength Resin residue on the surface of CFRP materials The bonding strength is 1.6 times that of the surface without laser cleaning [116] Continuous measurement of surface photocurrent Pure tungsten photocathode Real-time monitoring of cleaning effect [159] Surface roughness Metal A two-stage process parameter adjustment and surface roughness estimation algorithm based on image analysis was proposed [176] 表 5 国内部分单位对激光清洗的研究

Table 5. Research on laser cleaning in some domestic units

Organization Laser Wavelength/

nmCleaning object Base Pollutant Literature

(serial number)Nankai University Nd:YAG laser 150 Homemade sample Aluminium alloy Paint [229] Harbin Institute of Technology Nanosecond fiber pulse laser 30-100 Homemade sample Titanium alloy Oxide layer [230] Huazhong University of Science and Technology Pulse laser with maximum Power of 100 W (YDFLP-100-LM1) 100 Homemade sample Aluminium alloy Oxide layer [231] Jiangsu University IPG-HP-100 laser 100 Homemade sample Steel Oxide [232] Jinan University All solid state fiber coupled output laser 50 Aluminium alloy tyre mould Aluminium alloy Sulfide [233] Hunan Engineering and Technology Research Center of Aircraft Maintenance All-solid state quasi-continuous laser (IS-0604QCW) 100 Homemade sample Aluminium alloy Paint layer [234] 表 6 主要激光器和污染物

Table 6. Mainly used lasers and contaminants

Laser Type Wavelength/nm Cleaning contaminant Literature

(serial number)Excimer laser ArF, KrF 193, 248 Granules and paints [235] Nd:YAG laser Nd:YAG 352, 532, 1 064 Metal contaminant [236] Er:YAG laser Er:YAG 2 940 Pollutant cleaning of cultural relics [89] Fiber laser Fiber laser 1 064 Paint, rust [237] Gas laser CO2 laser 1 0.6 Paint on non-metallic materials [238] -